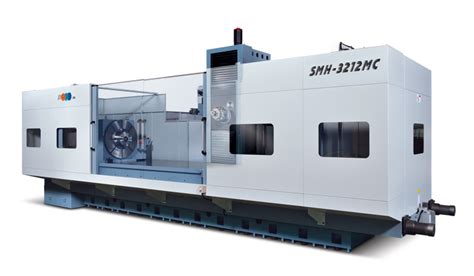

cnc hhv3 machine center The HHV3 can achieve up to 50% faster machining time over conventional processes, better than 95% machine up-time, and true lean and green production. To learn more about the Modig HHV3 or to schedule a demonstration, connect .

Non-standard turned parts are an integral component of various industries, providing customized solutions to meet specific design requirements. These specialized components offer a range of benefits, from enhanced functionality to improved efficiency and reliability.

0 · Horizontal High Velocity Machining Centers

1 · HHV3

2 · Equipment Spotlight: Modig HHV3 Machining Centers

3 · 5

The Red Hook Stores complex at the end of Van Brunt Street is now home to a Fairway Market. Originally known as the New York Warehouse Co.’s Stores, this structure dates back to the .

Horizontal machining center with 3 rotary tables. Options: Spindle power and torque, 4- or 5-axis, tool magazine and tool holder. Automation: Bar feeder system, robot loading/unloading. Materials: Aluminum and Composite. .The HHV is a universal machining center for bar or extrusion components. It is ideal for limited production runs, nesting, or high-volume production. Raw material is loaded from the left side into the machine, the HHV automatically pulls the .Horizontal High Velocity Machining Centers Developed in collaboration with the world’s leading aircraft manufacturers, the HHV 2, HHV 3 and HHV DUO are built for companies and organizations that demand the best possible machining .Horizontal machining center with 3 rotary tables. Options: Spindle power and torque, 4- or 5-axis, tool magazine and tool holder. Automation: Bar feeder system, robot loading/unloading. Materials: Aluminum and Composite. Industries: Automotive, Extrusion, Aerospace and more.

The HHV is a universal machining center for bar or extrusion components. It is ideal for limited production runs, nesting, or high-volume production. Raw material is loaded from the left side into the machine, the HHV automatically pulls the raw material into position for machining and delivers finished parts into a part catcher. The HHV3 can achieve up to 50% faster machining time over conventional processes, better than 95% machine up-time, and true lean and green production. To learn more about the Modig HHV3 or to schedule a demonstration, connect .

Horizontal High Velocity Machining Centers Developed in collaboration with the world’s leading aircraft manufacturers, the HHV 2, HHV 3 and HHV DUO are built for companies and organizations that demand the best possible machining .The HHV (Horizontal High Velocity) is a universal machining center for bar or extrusion components. It was developed in close cooperation with the world's largest aircraft manufacturers. Since its introduction, it quickly became the first choice of high-performance machine shops.

The HHV3 is a horizontal machining center that is available with four- or five-axis machining and one or two spindles for high-volume production. It handles uncut bars and extrusions of unlimited length and produces many parts from the same block of material.Technical specification for MODIG HHV3 3 rotary table machining centre | Significantly reduces cycle time, machines in one set up handling un cut raw materialsHHV3: Reduced cycle time up to 40-70%! Better chip flow with horizontal machining, and complete parts in one setup with no workholding. HHV3 has three rotary tables. See HHV3 technical specification for detailed information on the three rotary tables, axes, aluminium and hard metal spindles, tool changer, feed rates and acceleration.

The Modig HHV3 (Horizontal High Velocity) Machining Center is a favorite among busy machine shops due to.Horizontal machining center with 3 rotary tables. Options: Spindle power and torque, 4- or 5-axis, tool magazine and tool holder. Automation: Bar feeder system, robot loading/unloading.Horizontal machining center with 3 rotary tables. Options: Spindle power and torque, 4- or 5-axis, tool magazine and tool holder. Automation: Bar feeder system, robot loading/unloading. Materials: Aluminum and Composite. Industries: Automotive, Extrusion, Aerospace and more.

The HHV is a universal machining center for bar or extrusion components. It is ideal for limited production runs, nesting, or high-volume production. Raw material is loaded from the left side into the machine, the HHV automatically pulls the raw material into position for machining and delivers finished parts into a part catcher. The HHV3 can achieve up to 50% faster machining time over conventional processes, better than 95% machine up-time, and true lean and green production. To learn more about the Modig HHV3 or to schedule a demonstration, connect .

Horizontal High Velocity Machining Centers Developed in collaboration with the world’s leading aircraft manufacturers, the HHV 2, HHV 3 and HHV DUO are built for companies and organizations that demand the best possible machining .

The HHV (Horizontal High Velocity) is a universal machining center for bar or extrusion components. It was developed in close cooperation with the world's largest aircraft manufacturers. Since its introduction, it quickly became the first choice of high-performance machine shops.The HHV3 is a horizontal machining center that is available with four- or five-axis machining and one or two spindles for high-volume production. It handles uncut bars and extrusions of unlimited length and produces many parts from the same block of material.Technical specification for MODIG HHV3 3 rotary table machining centre | Significantly reduces cycle time, machines in one set up handling un cut raw materials

Horizontal High Velocity Machining Centers

HHV3: Reduced cycle time up to 40-70%! Better chip flow with horizontal machining, and complete parts in one setup with no workholding. HHV3 has three rotary tables. See HHV3 technical specification for detailed information on the three rotary tables, axes, aluminium and hard metal spindles, tool changer, feed rates and acceleration.

The Modig HHV3 (Horizontal High Velocity) Machining Center is a favorite among busy machine shops due to.

HHV3

Get the best deals on Victorian Original Vintage Hat Boxes when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

cnc hhv3 machine center|Horizontal High Velocity Machining Centers