process of manufacturing sheet metal I have not discussed any sheet metal operation here. I am discussing the consideration which a designer should use so that sheet metal parts do not get deform while manufacturing. Overall, 20 considerations have been discussed in the course. Students can make a list of all the points and use the values when they are designing parts in sheet metal.

1 was here. For all of your metal fabrication needs come to Tresco Metal Fabrication. We specialize in.

0 · types of sheet metal fabrication

1 · sheet metal processes pdf

2 · sheet metal operations with diagrams

3 · sheet metal manufacturing process types

4 · sheet metal manufacturing process pdf

5 · sheet metal manufacturing news

6 · how to fabricate sheet metal

7 · forming operation in sheet metal

Round Cover Trim Rings Enerlites 975509-S – Nickel-Plated Brass 4″ Round Floor Box Trim Ring $

The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material .

cnc automatic lathe machined part

Sheet Metal Manufacturing Process Engineer. New. Confidential. Alpharetta, GA 30004. From ,000 a year. Full-time. Easily apply. Estimates manufacturing costs, process time studies and manpower requirements. Hands-on experience in manufacturing, facilities, equipment. Employer Active 2 days ago.A sheet metal manufacturing process consists of the following basic steps: 1. Set up the manufacturing database. It may contain such items as workcells (machine tools) available, tooling, site parameters, etc. If you do not want to set up all your database up front, go directly into the machining process and define any of the items above when . Sheet metal fabrication is a widely used manufacturing process that transforms flat sheets made from various metals, mainly steel, and aluminum, into functional shapes and structures. It does so by cutting, punching holes, and folding the metal sheets to achieve the.

types of sheet metal fabrication

Shearing is a fundamental manufacturing process within sheet metal fabrication, serving as a primary method for cutting and shaping flat metal sheets. This process involves the use of shearing machines equipped with sharp blades, where the upper blade descends against the lower blade to cut through the sheet material. Shearing is particularly .I have not discussed any sheet metal operation here. I am discussing the consideration which a designer should use so that sheet metal parts do not get deform while manufacturing. Overall, 20 considerations have been discussed in the course. Students can make a list of all the points and use the values when they are designing parts in sheet metal.

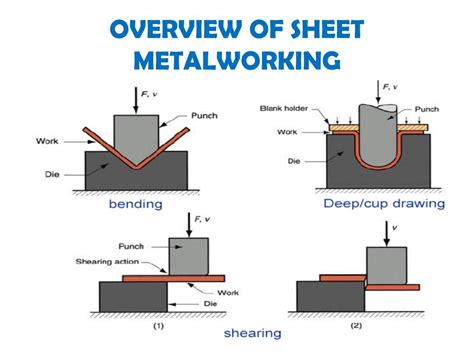

Sheet metal manufacturing plays a crucial role in fulfilling the requirements of various engineering processes. When engineering specifications dictate the use of sheet metal, it undergoes a fabrication process. Sheet metal crafting encompasses a range of techniques including shearing, bending, notching, shrinking, and beading. The sheet metal blanking process is a fundamental aspect of the manufacturing industry that converts flat metal sheets into specific, predefined shapes for a variety of uses. This method is known for its efficiency and is especially advantageous for high-volume production. Let’s take a closer look at how sheet metal blanking operates. Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high strength-to-weight ratio, durability, and versatility. This guide will provide a comprehensive overview of precision sheet metal fabrication techniques, applications, and best practices.Sheet Metal Manufacturing Processes: Sheet metal manufacturing encompasses the fabrication of sheet metal components through cutting, bending, and shaping thin metal sheets into precise configurations and dimensions. This process commonly involves employing coating, cutting, bending, and assembly methodologies.

sheet metal processes pdf

sheet metal operations with diagrams

The Advantages Of Precision Sheet Metal Fabrication Process. The precision sheet metal fabrication process is ideal for high-quality manufacturing due to the various benefits it offers. For example: Customization: This process allows manufacturers to produce parts and components tailored to meet precise requirements. They just need to modify .

Sheet metal fabrication is a dynamic process that involves various shearing processes depending on industry requirements. It involves piercing, punching or blanking during the manufacturing process, depending on the end product.

During the process of sheet metal manufacturing, if a sheet metal part requires welding, PMF is more than capable of filling that need. We are equipped with 2 spot welding stations and we also employ traditional welders who are experienced in both MIG and TIG welding practices. In addition, in an effort to lessen the cost associated with .

The sheet metal stamping process is a strategic advantage that can set your business apart. Precision, efficiency, and innovation are at its core, driving the production of high-quality components. Precision, efficiency, and innovation are at its core, driving the production of high-quality components. Although it is not always considered a fabrication process, the assembly of disparate components of sheet metal parts using fasteners bolts, screws, and rivets is an important part of the overall manufacturing process. Other sheet metal fabrication processes like punching may be carried out explicitly to make holes for rivets and other fasteners. The process of computer-aided design and manufacturing of sheet metal parts starts with computer-aided design, goes through numerical simulation unfolding, nesting, cutting, stamping, bending, and other procedures, and . Mastering sheet metal design is key to achieving both precision and efficiency in manufacturing sheet metal parts. By incorporating Design for Manufacturing (DFM) principles, you can streamline production, reduce costs, and maintain high-quality standards. Whether you’re working with steel, aluminum, or copper, understanding the nuances of sheet metal processing .

The first step of the shearing sheet metal process is the setup for the shear itself. . Yes, the shearing and forming manufacturing process can be automated using CNC (Computer Numerical Control) shearing machines. .The manufacturing features of sheet metal have been researched, e.g. by Wang [4] who has studied sheet metal parts bending with a robotized bending machine. When designing the manufacturing process of a sheet metal product, one should take into account not only individual features and geometries, but also their combinations.

For sheet manufacturers, maintaining stable production, meeting quality specifications, and minimizing energy consumption are the keys to profitability. . Sheet Manufacturing. Pulp & Paper; Films Metals Coatings And Calendering; Lithium Ion Batteries; Chemicals. . View All Discontinued: Process Instruments DCP50 DIN Programmer; DL4000 . Sheet Metal Stamping is a low-cost high-speed manufacturing process that produces a high volume of identical metal components, which has contributed importan.

Conclusion: The Path to Cost-Effective Sheet Metal Fabrication. Sheet metal fabrication is a critical part of manufacturing, and optimising costs in its design and production will improve competitiveness and profitability. By implementing cost-effective strategies from the outset, you can lower expenses, reduce waste, and improve efficiency.The common materials used in manufacturing sheet metal are aluminum and stainless steel. The most known grades available in stainless steel are 304, 316 and 410. 304 is one of the most common grades. . Sheet metal forming process is done on a press and the parts are formed in between two die. The die at the top is called a punch. Sheet metal . In conclusion, sheet metal hydroforming is a versatile and efficient manufacturing process that offers numerous advantages for engineers and manufacturers. It allows for the production of complex parts with tight tolerances, smooth surfaces, and reduced material waste.

The fabrication process of sheet metal can involve longer production times, especially for complex parts. Multiple steps such as cutting, bending, and assembling are often required, each adding to the overall production time. Advanced techniques and precision requirements can further extend the manufacturing process.

sheet metal manufacturing process types

Sheet metal fabrication is a highly versatile manufacturing process that creates complex parts and structures from metal sheets. From cellphones and kitchenware to submarines and rockets, numerous industries utilise this process to create a wide range of products and technologies that shape our daily lives and facilitate technological advancement. Sheet metal machines are widely used in various manufacturing industries for shaping, cutting, and forming sheet metal into different components. . Stamp press technology, also known as stamping or pressing, is a manufacturing process that utilizes a press to shape or cut materials into desired forms. This process involves the use of a die . These detailed drawings are crucial for accurate fabrication, quality control, and communication between design and manufacturing teams in sheet metal work. . Bending is a fundamental sheet metal forming process that transforms 2D flat parts into 3D components with precise angles and contours.

sheet metal manufacturing process pdf

Trenton Sheet Metal Profile and History. Trenton Sheet Metal custom fabricates all types of metal, as well as plasma cutting, shearing, cnc punching, bending, welding, metal cutting, metal stamping and metal rolling.

process of manufacturing sheet metal|sheet metal manufacturing process pdf