electrical rough in boxes plugs Wire Strippers https://amzn.to/3e6jq2UIn this video I will show you how to install rough in electricity in a new construction house. This is how to do wire a. There is a black box with a flexible handle inside the raised portion. It has two bolts coming down from the top near where the seatbelt latches are mounted. Anybody know what this box is for?

0 · roughing in electrical outlets

1 · rough in electrical wiring layout

2 · residential wiring rough in guide

3 · residential electrical rough in checklist

4 · electrical rough in symbols

5 · electrical rough in material list

6 · electrical rough in inspection guidelines

7 · electrical rough in check list

This article dives into the properties, types, and applications of galvanized sheet metal, revealing its effectiveness in rust prevention and durability. From hot-dip to electro-galvanized sheets, discover the different methods of galvanization and their specific advantages.

roughing in electrical outlets

Wire Strippers https://amzn.to/3e6jq2UIn this video I will show you how to install rough in electricity in a new construction house. This is how to do wire a.At the rough-in stage, inspectors look for a few key signs of a job well done: cables properly sized for the loads they’ll carry; the requisite number and type of outlets specified by code; cables protected by nail plates as needed; neat, . But the wiring has not been connected to your breaker box and the various switches, outlets, and receptacles have not yet been installed. With the information provided here and some basic tools, you can do rough-in wiring . To clarify, roughing in as an electrician refers to pulling wring, drilling holes, mounting box heights for receptacles and light switches, or bending emt pipe, building pipe racks, building an electrical room, or even looking at .

Here’s one of my favorite videos discussing the rough-in process. It doesn’t get crazy technical and it doesn’t get to the stage of installing switches and plugs, but here’s what it does cover: Basics of electrical and wiring rough-in code; Proper . Installing rough electricity involves running electrical wiring, installing outlet boxes, and setting up light fixtures before the walls are closed. It’s really a job for a licensed electrician. In this video and guide, This Old House electrician Scott Caron discusses the key steps for installing rough electricity in a newly framed basement room. Mark the height from the floor to the center of the boxes (usually 48 in. for switches and 12 in. for outlets) or line them up with existing boxes to determine electrical outlet height. Use letters and symbols to identify boxes. Add 2×4 blocks to .

Wire Strippers https://amzn.to/3e6jq2UIn this video I will show you how to install rough in electricity in a new construction house. This is how to do wire a.At the rough-in stage, inspectors look for a few key signs of a job well done: cables properly sized for the loads they’ll carry; the requisite number and type of outlets specified by code; cables protected by nail plates as needed; neat, consistent work throughout the system; and, above all, ground wires spliced and, in metal boxes, secured . But the wiring has not been connected to your breaker box and the various switches, outlets, and receptacles have not yet been installed. With the information provided here and some basic tools, you can do rough-in wiring yourself and save some money on your project. To clarify, roughing in as an electrician refers to pulling wring, drilling holes, mounting box heights for receptacles and light switches, or bending emt pipe, building pipe racks, building an electrical room, or even looking at electrical prints and understanding panel and equipment schedules.

Here’s one of my favorite videos discussing the rough-in process. It doesn’t get crazy technical and it doesn’t get to the stage of installing switches and plugs, but here’s what it does cover: Basics of electrical and wiring rough-in code; Proper measurements and placement of boxes and switches; Stripping wires and running them to boxesRough-in Recap: Electrical Code Circuit breakers, wiring, and devices must be correctly sized for the loads they carry. For example, 20-amp circuits require 12AWG wire and receptacles rated for no greater than 20 amps. Knowing how to rough in electrical wiring ensures that the foundational electrical work is done correctly, paving the way for a safe and efficient final installation. Can I do electrical rough-in by myself? Yes, with the right tools and knowledge, you can undertake a .

In the industry, that part of wiring is called “roughing in.” Before running cable, the author marks the location of every switch and notes what that switch will control. He also indicates if a switch is a 3- or 4-way. A circle with two lines indicates a receptacle location. Installing rough electricity involves running electrical wiring, installing outlet boxes, and setting up light fixtures before the walls are closed. It’s really a job for a licensed electrician. In this video and guide, This Old House electrician Scott Caron discusses the key steps for installing rough electricity in a newly framed basement room.

Mark the height from the floor to the center of the boxes (usually 48 in. for switches and 12 in. for outlets) or line them up with existing boxes to determine electrical outlet height. Use letters and symbols to identify boxes. Add 2×4 blocks to .

Wire Strippers https://amzn.to/3e6jq2UIn this video I will show you how to install rough in electricity in a new construction house. This is how to do wire a.

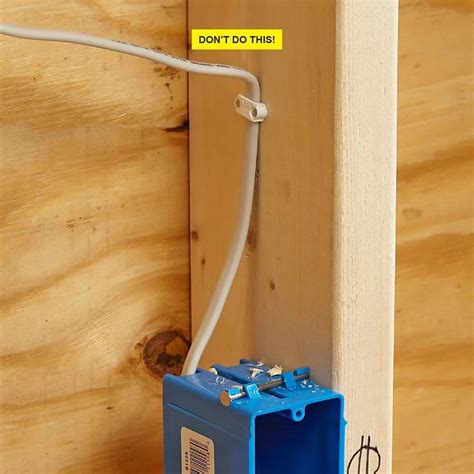

At the rough-in stage, inspectors look for a few key signs of a job well done: cables properly sized for the loads they’ll carry; the requisite number and type of outlets specified by code; cables protected by nail plates as needed; neat, consistent work throughout the system; and, above all, ground wires spliced and, in metal boxes, secured .

But the wiring has not been connected to your breaker box and the various switches, outlets, and receptacles have not yet been installed. With the information provided here and some basic tools, you can do rough-in wiring yourself and save some money on your project. To clarify, roughing in as an electrician refers to pulling wring, drilling holes, mounting box heights for receptacles and light switches, or bending emt pipe, building pipe racks, building an electrical room, or even looking at electrical prints and understanding panel and equipment schedules.Here’s one of my favorite videos discussing the rough-in process. It doesn’t get crazy technical and it doesn’t get to the stage of installing switches and plugs, but here’s what it does cover: Basics of electrical and wiring rough-in code; Proper measurements and placement of boxes and switches; Stripping wires and running them to boxesRough-in Recap: Electrical Code Circuit breakers, wiring, and devices must be correctly sized for the loads they carry. For example, 20-amp circuits require 12AWG wire and receptacles rated for no greater than 20 amps.

Knowing how to rough in electrical wiring ensures that the foundational electrical work is done correctly, paving the way for a safe and efficient final installation. Can I do electrical rough-in by myself? Yes, with the right tools and knowledge, you can undertake a .

rough in electrical wiring layout

how to turn an outlet into a junction box

What Does a Sheet Metal Mechanic Do? A sheet metal mechanic works with various thin sheets of metal materials to fabricate, install, and repair products and parts made from sheets of metal. Their direct supervisor may be a sheet metal supervisor, shop manager, production manager, or general contractor depending on their place of employment.

electrical rough in boxes plugs|rough in electrical wiring layout