sheet metal bending calculation Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time. Husky has different lines and therefore different gauge steel in each. Going from 20-22 gauge on the lowest end stuff to 18-19 on the midrange stuff (which is pretty expensive already), and then 16 gauge on the pro level stuff. I can't say for .

0 · sheet metal calculation formula

1 · sheet metal bending formula

2 · sheet metal bending calculator free

3 · sheet metal bending calculation formula

4 · sheet metal bending angle chart

5 · online sheet metal bending calculator

6 · blank size calculator sheet metal

7 · bend allowance calculator for sheet metal

Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, .

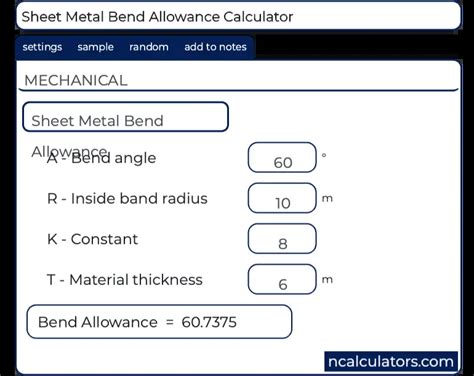

Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and .

Learn how to calculate bend allowance, outside setback, and bend deduction for sheet metal parts. See formulas, examples, and tips for flat-blank layout and spri.

sheet metal calculation formula

sheet metal bending formula

Use SendCutSend’s bending calculator to input your desired material . Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time. Learn how to calculate the length of a sheet metal bend using the bend allowance formula and the K-factor. This tool also works as a bend deduction calculator for different bend angles and radii. Our bend deduction calculator helps you calculate the correct values for your sheet metal bending projects, ensuring accurate results and minimal waste. Try it out for free today!

K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. In this article, we will discuss .Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and KnightHow to calculate tonnage, internal radius and other bend parameters. This tool allows you to determine tonnage, internal radius, V-die opening and minimum flange.You just have to insert the characteristics of the sheet metal to be bent.Key Features. Accurate Calculations: Provides precise bend allowance and bend deduction values. User-Friendly Interface: Simple and intuitive design for easy use. Automatic Calculation: Real-time updates as you input values. Versatility: Suitable for various sheet metals, including stainless steel and aluminum. Benefits of Using Our Calculator. Enhanced Accuracy: Minimize .

The bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length. The bend allowance describes the length of the neutral axis between the bend lines, or in other words, the arc length of the bend. Therefore, the bend allowance added to the flange lengths is equal to the total flat . Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape.. This is done through the application of force on a workpiece. The force must exceed the material’s yield strength to achieve plastic deformation.Sheet Metal; Bend Allowance; Bending Springback; V-Bending Force; Wipe Bending Force; Deep Drawing Force; Bend Allowance Calculator. Sheet thickness (in): . V-Bending Force Calculator. Sheet thickness (in): Die ratio: Die opening (in): Bend length (in): Ultimate tensile strength (psi): Factor of safety: Bending force (lb):

Sheet Metal Unfold Rule Equations. Register for more free training on this topic at KETIV Virtual Academy. Register Now. Free training, every week, from real experts. 9HUVLRQ 1R 3DJH RI .(7,9 $ &RQWHQWVAdvanced Calculation Considerations. Springback Compensation: To account for springback, a correction factor is often applied to the initial bend angle.This factor varies with material type and thickness. Die and Punch Clearance: Proper clearance between the die and punch is crucial to prevent excessive thinning or cracking.A general rule of thumb is to maintain a clearance of .The TRUMPF BendGuide app performs bending calculations more easily and clearly than ever before. Discover the BendGuide app from TRUMPF – your solution for precise and efficient bending. With intuitive operation and innovative technology for optimal bending results. . Sheet metal weight calculation; Download the app In the "More" menu item .

Sheet Metal Bending Parameters Calculator Here you can insert the characteristics of the sheet metal to be bent (internal radius, V-die opening and minimum flange) . The tool can calculate the required bending force for bending aluminum, stainless steel, mild steel. Bending Force Calculation Our press brake bending calculator can help you based on the [.] 90 Degrees Bend Angle. Figure 2 illustrates the sheet that is bent with the bend angle of 90 degrees. We will start by calculating the Bend Allowance. From there we can calculate the K-Factor and the Bend Deduction. After bending the sheet we need to do some measurements as shown in Figure 2.Bending Springback Calculator. After a bending operation, residual stresses will cause the sheet metal to spring back slightly. Due to this elastic recovery, it is necessary to over-bend the sheet a precise amount to acheive the desired bend radius and bend angle. The final bend radius and bend angle can be approximated from the sheet thickness .K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of neutral axis and sheet thickness. During sheet metal part bending, the inside bending surface is compressed, whereas the outer surface is stretched.

sheet metal bending calculator free

The variables in this formula include: S: Sheet thickness; r: Inner radius during bending; K: Width of the horizontal projection of the bending deformation zone; From the derivation process, it is essential to meet two additional conditions when using formulas (2) or (3) to calculate bending force: the width-to-thickness ratio (V/S) must equal 9, and the radius-to-width ratio must equal .Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and fracturing in hard material. Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part. For instance, if the sheet metal to be bent is mild steel, with a thickness of 4mm and a bending length of 3.2m, the theoretical width of the bottom die opening should be 8 times the thickness, which is 32mm. Input these figures into the calculator above (remember the units are in .Online bend deduction calculator. Automatically calculate bend deduction, bend allowance and K-factor for sheet metal fabrication and forming. Skip to content. Request a Quote (916) 419-0580; Search. Toggle navigation Menu [email protected] (916) 419-0580; Services. Services;

Sheet Bending Calculator is used to calculate sheet bending allownace, bend deductions, sheet bending plate raw size Sheet Bending Calculator is very helpful in sheet metal fabrication industry, process equipent fabrication industry, heavy equipment fabrication and sheet metal indutsry. Bend allowance and bend deduction calculations are essential methods used to determine the length of sheet metal raw materials in their flat form, ensuring the desired size of the bent part is achieved. Understanding these calculations is crucial for precision in sheet metal fabrication. Bend Allowance Calculation Method:

BendCalc is a bend deduction and bend allowance calculator for sheet metal air-bending. Actually BendCalc is more than that, BendCalc is five calculators in one. . Calculator 2: Calculates Bend Deduction and Bend Allowance given bend angle, material .

Defining Bend Calculation. When designing sheet metal with the Sheet Metal model feature, locate the Material > Bend Calculation option in the dialog. The dropdown options are: K Factor: A dimensionless factor representing the ratio of the neutral axis length to the material thickness during bending. It is a common choice for many sheet metal . Have you ever wondered how to calculate the exact force needed to bend metal sheets? This article will introduce you to the V & U-shaped Bend Force Calculator, a powerful tool in sheet metal fabrication. By the end, you'll understand its importance and how it ensures precision in your projects. Let's dive in!Metal bending involves the deformation of a metal sheet along a straight axis, altering its shape without reducing its cross-sectional area. Accurate bending calculations are essential to prevent material failure, such as cracking, buckling, or excessive thinning, which can compromise the structural strength and aesthetics of the final product. For the Bend Calculation option, the spreadsheet applies one of three equations – depending on the angle of the bend – to the sheet metal design. With the Bend Table option, each of the available tables extracts the values for Bend Allowance – as it relates to the various radii and material thicknesses – from the Machinery Handbook.

CNC bending opens up laser cut sheet metal to a new world of possibilities, turning your 2D parts into 3D. To help make sure you get your bends the correct sizes and in the right places we’ve created a Bending Calculator tool that calculates the complicated bend allowance and bend deduction values for you.Sheet Metal Bending Equation and Calculator. Manufacturing Knowledge Menu Sheet Metal Knowledge. The following illustration shows the equation / calculation for determining the bend line to mold allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line calculator.

sheet metal bending calculation formula

sheet metal bending angle chart

online sheet metal bending calculator

blank size calculator sheet metal

Thanks to this site, I am now aware of what a SJB is, and what I need to do to fix it. The only real question is.if I unplug the SJB and take it out to clean it, will it reset any programming in the box???Learn what a sheet metal worker does, including duties, skills, types, and workplace. Find out how to become a sheet metal worker and explore related careers.

sheet metal bending calculation|online sheet metal bending calculator