sheet metal tabs When designing your sheet metal parts with tab and slots for laser cutting with SendCutSend, keep material thickness and finishes in mind. 314.29 says boxes have to be accessable without removing any part of the building. I'm doing a bathroom remodel that was originally wired with emt with a vanity light on each .

0 · solidworks add sheet metal tab

1 · sheet metal tabs and slots

2 · sheet metal tab solidworks

3 · sheet metal folding techniques

4 · laser cut tabs and slots

5 · interlocking sheet metal joints

6 · interlocking sheet metal design

7 · crimping process in sheet metal

Junying precision CNC aluminum 6063 components go through milling, turning, drilling and more processes, equipped with 6 advanced CNC milling centers and skilled operators, our 6063 aluminum CNC products can reach your custom requirements. Aluminum 6063 is a medium-strength aluminum alloy with magnesium and silicon as the alloying elements.

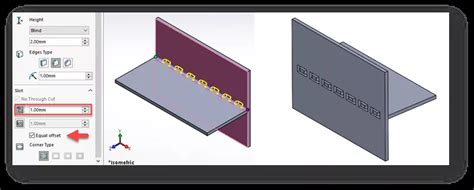

Sheet metal fabrication uses notches and tabs to make further machining operations easier and eliminate space conflicts during assembly. This article will go through several types of notches, dimensioning & tolerancing . At Approved Sheet Metal, we regularly add slots and tabs to weldment components—a process most metal fabrication shops don’t undertake. Slot and tab features perform two critical functions: Slots & tabs enable self .Sheet Metal Tabs. The depth of a tab feature is automatically set to the thickness of the sheet metal part. The direction of the depth automatically coincides with the sheet metal part to prevent a disjoint body. The sketch can be a single closed, .In 2018, Solidworks added a “tab and slot” feature in the sheet metal menu. This allows the user to drastically speed up the process for the designer to add these features. Undoubtedly, this .

When designing your sheet metal parts with tab and slots for laser cutting with SendCutSend, keep material thickness and finishes in mind. The release of SOLIDWORKS 2018 added a great sheet metal feature called Tab and Slot. Tabs and slots can be added to adjoining components to create an interlock between them. The feature can be added to .

The Tab feature allows you to add a tab to a sheet metal flange, remove interfering material if appropriate, or bridge two flanges from the same sheet metal model. Tabs are reflected in the model and in the flat pattern. Creating tabs is a common punching application. Tabs are used to keep the part attached to the sheet so it can be easily broken free once it’s removed from the machine. The .

14x14 outdoor electrical pull box door cover

Creating Sheet Metal Tabs just got a lot easier with Onshape’s most recent update. A new Sheet Metal Tab command was added that makes this a simple task. Let’s take a look. You’ll find the new Tab command with the rest of the . A look at 3 ways of adding temporary Tabs to a sheet metal part. And how we can use Multibody modelling to solve a flat pattern operation unsuccessful issue.The sketch can be a single closed, multiple closed, or multiple-enclosed profile. The illustration shows a single tab feature that adds two tabs to the sheet metal part. The sketch must be on a plane or planar face that is perpendicular to the direction of thickness of the sheet metal part. You can edit the sketch. When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Tab - Add a tab .

You’re done. That’s all it takes to create a simple Sheet Metal Tab in Onshape. But the Sheet Metal Tab command can do more than create a single Sheet Metal Tab. You can also create multiple tabs in the same feature by selecting more parallel flanges to merge with. Or you can even create flanges on two separate parts in the same feature.The sketch can be a single closed, multiple closed, or multiple-enclosed profile. The illustration shows a single tab feature that adds two tabs to the sheet metal part. The sketch must be on a plane or planar face that is perpendicular to the direction of thickness of the sheet metal part. You can edit the sketch. When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Tab - Add a tab to a sheet metal flange.; Make joint - Convert the intersection of two walls into a joint feature, either a bend (walls joined by cylindrical geometry) . Slots and Tabs for Weldment Components Picture a four-sided box with flanges that are 8” high. To weld the box’s corner seams, most shops apply clamps or other fixtures to hold the sides in place at the correct angles—a time-consuming task that can double the welding time. Adding slots & tabs to the box’s sides makes those sides self-fixturing, eliminating the .

The sketch can be a single closed, multiple closed, or multiple-enclosed profile. The illustration shows a single tab feature that adds two tabs to the sheet metal part. The sketch must be on a plane or planar face that is perpendicular to the direction of thickness of the sheet metal part. You can edit the sketch.

The sketch can be a single closed, multiple closed, or multiple-enclosed profile. The illustration shows a single tab feature that adds two tabs to the sheet metal part. The sketch must be on a plane or planar face that is perpendicular to the direction of thickness of the sheet metal part. You can edit the sketch.

Incorporating slot and tab features into your sheet metal parts increases flexibility, decreases cost during fabrication, and allows for a more streamlined design process. Please note that the numbers in this article lean on the conservative end and that for large-scale production runs, we recommend testing the sizes first.For Sheet Metal users, the new features in SOLIDWORKS 2025 are sure to excite. See everything new in SOLIDWORKS 2025 Sheet Metal here. SOLIDWORKS. 3D CAD . at least the first time until you customize it onto your Sheet Metal tab or shortcut bar (as shown below). So typing 's' and then 'be' will be enough. Collect All Bends makes it easy for .The sketch can be a single closed, multiple closed, or multiple-enclosed profile. The illustration shows a single tab feature that adds two tabs to the sheet metal part. The sketch must be on a plane or planar face that is perpendicular to the direction of thickness of the sheet metal part. You can edit the sketch.Our trick tabs are stamped from premium mild steel and go through a full tumbling process to remove any burrs or imperfections. All of our trick tabs start off as flat tabs, then they are formed in a Forming Die to create the “winged” or “3-dimensional” tab. Radius Tab 101: Radius tabs can be either formed or flat. Each of these tabs .

Hello all, Does anyone know a way to make a simple tab in sheet metal? When I do a bend it bends the entire edge. To do a partial, it seems I have to create a sketch first, create a floating face, then create the bend between the two edges to connect them. I'm used to Creo, where we create a bend, then we can simply offset one or both ends right there in the bend tool.

The sketch can be a single closed, multiple closed, or multiple-enclosed profile. The illustration shows a single tab feature that adds two tabs to the sheet metal part. The sketch must be on a plane or planar face that is perpendicular to the direction of thickness of the sheet metal part. You can edit the sketch.The sketch can be a single closed, multiple closed, or multiple-enclosed profile. The illustration shows a single tab feature that adds two tabs to the sheet metal part. The sketch must be on a plane or planar face that is perpendicular to the direction of thickness of the sheet metal part. You can edit the sketch.Properties of tab sketches include: The sketch can be a single closed, multiple closed, or multiple-enclosed profile. The illustration shows a single tab feature that adds two tabs to the sheet metal part. The sketch must be on a plane or planar face that is perpendicular to the direction of thickness of the sheet metal part.

Properties of tab sketches include: The sketch can be a single closed, multiple closed, or multiple-enclosed profile. The illustration shows a single tab feature that adds two tabs to the sheet metal part. The sketch must be on a plane or planar face that is perpendicular to the direction of thickness of the sheet metal part.

Use the Sheet Metal tab to link the sheet metal parameters to the material. If you change the material, the sheet metal parameters also update. Options on this tab are available for custom materials only. To display this dialog box: When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Hem - Create a hem for each edge/face selected, on an existing sheet metal part.; Tab - Add a tab to a sheet metal flange.; Bend - Bend a sheet metal model .

Weld tabs, brackets, and metal fabrication products. Our weld tabs are stamped, not flame cut. Made in the USA from American steel. . When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Tab - Add a tab to a sheet metal flange.; Make joint - Convert the intersection of two walls into a joint feature, either a bend (walls joined by cylindrical geometry) . When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Hem - Create a hem for each edge/face selected, on an existing sheet metal part.; Tab - Add a tab to a sheet metal flange.; Bend - Bend a sheet metal model .

Properties of tab sketches include: The sketch can be a single closed, multiple closed, or multiple-enclosed profile. The illustration shows a single tab feature that adds two tabs to the sheet metal part. The sketch must be on a plane or planar face that is perpendicular to the direction of thickness of the sheet metal part.

I know this is inanely simple, but I cannot get the sheet metal tab to dock at the top with the rest of the toolbars. Dragging to the selection yields no results, and it's driving me mad. How do I get this thing to dock correctly? Student Edition 2019/2020 Edit: Solved my own problem. For the googlers: Right Click on another tab in the toolbar .

The sketch can be a single closed, multiple closed, or multiple-enclosed profile. The illustration shows a single tab feature that adds two tabs to the sheet metal part. The sketch must be on a plane or planar face that is perpendicular to the direction of thickness of the sheet metal part. You can edit the sketch.

When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Hem - Create a hem for each edge/face selected, on an existing sheet metal part.; Tab - Add a tab to a sheet metal flange.; Bend - Bend a sheet metal model .

solidworks add sheet metal tab

Take a look at our precision OEM CNC milling aluminum parts for machines, and get an instant free quote online. 6061 is a popular grade in the aluminum alloy family due to its high corrosion resistance, good formability, and weldability. 6061-T6 aluminum refers to the aluminum alloy that has been given a solution heat treatment followed by quenc.

sheet metal tabs|solidworks add sheet metal tab