can pvc structural foam be cnc machined For projects requiring machining foam or fabrication of foam there is a require to use CNC routers or a combo of a CNC hot wire foam cutter with a router program. Full scale .

Metal Sheets at Tractor Supply Co. Buy online, free in-store pickup. Shop today!

0 · pvc foam cutting rate

1 · cutting foam with cnc router

2 · cutting foam with cnc

3 · cnc foam milling tools

4 · cnc foam cutting rate chart

A white house with a black roof creates an enduringly stylish contrast that adds depth, sophistication, and character to any home. This classic pairing balances the airy brightness of white with the bold stability of black, achieving an aesthetic that feels both timeless and modern.

Advice on feed rates, cutter choice, and RPMs when cutting sheet PVC foam on CNC equipment. March 21, 2006

PVC foam boards are easily handled and can be machined using circular saws, jigsaws, and CNC machines. Craft a work of art with materials that are easily milled, shaped, and molded using standard woodworking tools. A: Approximately three types of PVC are amenable to CNC machining, including unplasticized PVC (uPVC), chlorinated PVC (CPVC), and some grades of plasticized PVC. .

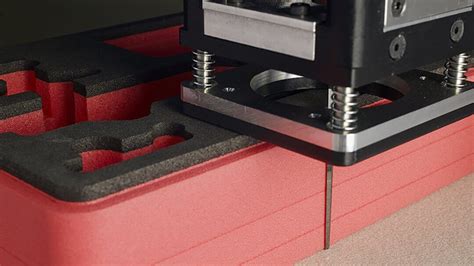

Cutting foam with a CNC router is a popular and versatile process that offers the ability to precisely shape and carve foam materials for use in several industries. Read ahead to learn more about cutting foam with a CNC . PVC foam board can be CNC. As a highly machinable plastic building board, PVC foam board has an expanded closed-cell core, which gives it a lighter weight an.

For projects requiring machining foam or fabrication of foam there is a require to use CNC routers or a combo of a CNC hot wire foam cutter with a router program. Full scale . PVC foam board can be CNC. As a highly machinable plastic building board, PVC foam board has an expanded closed-cell core, which gives it a lighter weight and makes it easier to CNC than traditional common PVC . Learn how to select the right plastic for CNC machining. Avoid pitfalls, ensure optimal performance, and reduce costs for your CNC machined parts with our comprehensive guide. E-pvc can be used for short- and medium-term indoor and outdoor applications and long-term interior applications. Another material option for signage is a paper-faced foam board. It can be used for short- to medium-term .

If you need to create a foam shape design that is large or even full scale you can use a small model, scan it using a 3D scanner then transport it into the CNC router for machining, using a specialty cutting software that .

Advice on feed rates, cutter choice, and RPMs when cutting sheet PVC foam on CNC equipment. March 21, 2006 PVC foam boards are easily handled and can be machined using circular saws, jigsaws, and CNC machines. Craft a work of art with materials that are easily milled, shaped, and molded using standard woodworking tools. A: Approximately three types of PVC are amenable to CNC machining, including unplasticized PVC (uPVC), chlorinated PVC (CPVC), and some grades of plasticized PVC. Depending on application requirements, one may choose any. uPVC allows a good combination of rigidity and machining, as it is mostly used, whereas CPVC gives better resistance to .

Cutting foam with a CNC router is a popular and versatile process that offers the ability to precisely shape and carve foam materials for use in several industries. Read ahead to learn more about cutting foam with a CNC automated router. 1. What Kinds Of Foam Can Be Cut With A CNC Router?

PVC foam board can be CNC. As a highly machinable plastic building board, PVC foam board has an expanded closed-cell core, which gives it a lighter weight an. For projects requiring machining foam or fabrication of foam there is a require to use CNC routers or a combo of a CNC hot wire foam cutter with a router program. Full scale racing cars, 3D topographic maps (up to 10’x5’x20″ on a single reduce), props and art work can all be machined, and foam molds can also be developed. PVC foam board can be CNC. As a highly machinable plastic building board, PVC foam board has an expanded closed-cell core, which gives it a lighter weight and makes it easier to CNC than traditional common PVC solid sheets. Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 [.] Learn how to select the right plastic for CNC machining. Avoid pitfalls, ensure optimal performance, and reduce costs for your CNC machined parts with our comprehensive guide.

E-pvc can be used for short- and medium-term indoor and outdoor applications and long-term interior applications. Another material option for signage is a paper-faced foam board. It can be used for short- to medium-term interior applications but is not routable because of the paper, which tears. If you need to create a foam shape design that is large or even full scale you can use a small model, scan it using a 3D scanner then transport it into the CNC router for machining, using a specialty cutting software that generates the part file.Advice on feed rates, cutter choice, and RPMs when cutting sheet PVC foam on CNC equipment. March 21, 2006

how much electrity does a box fan use

PVC foam boards are easily handled and can be machined using circular saws, jigsaws, and CNC machines. Craft a work of art with materials that are easily milled, shaped, and molded using standard woodworking tools. A: Approximately three types of PVC are amenable to CNC machining, including unplasticized PVC (uPVC), chlorinated PVC (CPVC), and some grades of plasticized PVC. Depending on application requirements, one may choose any. uPVC allows a good combination of rigidity and machining, as it is mostly used, whereas CPVC gives better resistance to . Cutting foam with a CNC router is a popular and versatile process that offers the ability to precisely shape and carve foam materials for use in several industries. Read ahead to learn more about cutting foam with a CNC automated router. 1. What Kinds Of Foam Can Be Cut With A CNC Router?PVC foam board can be CNC. As a highly machinable plastic building board, PVC foam board has an expanded closed-cell core, which gives it a lighter weight an.

For projects requiring machining foam or fabrication of foam there is a require to use CNC routers or a combo of a CNC hot wire foam cutter with a router program. Full scale racing cars, 3D topographic maps (up to 10’x5’x20″ on a single reduce), props and art work can all be machined, and foam molds can also be developed. PVC foam board can be CNC. As a highly machinable plastic building board, PVC foam board has an expanded closed-cell core, which gives it a lighter weight and makes it easier to CNC than traditional common PVC solid sheets. Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 [.] Learn how to select the right plastic for CNC machining. Avoid pitfalls, ensure optimal performance, and reduce costs for your CNC machined parts with our comprehensive guide.

E-pvc can be used for short- and medium-term indoor and outdoor applications and long-term interior applications. Another material option for signage is a paper-faced foam board. It can be used for short- to medium-term interior applications but is not routable because of the paper, which tears.

pvc foam cutting rate

The corded drill would have metal gears because there's more power in an AC motor, and that power is always there. The last sentence of your posts makes it sound like .

can pvc structural foam be cnc machined|pvc foam cutting rate