electrical trough vs junction box A pull box describes an electrical box that gives access to pull electrical cables through non-metallic or metallic raceways and conduit. They give you a means to pull . This includes perhaps the most important core business system at many metal fabricators: the enterprise resource planning (ERP) platform. What Is ERP?

0 · junction box wiring diagram

1 · junction box vs electrical box

2 · electrical pull boxes

3 · electrical junction box vs pull box

4 · electrical junction box sizes

5 · electrical junction box installation

6 · electrical junction box

7 · e-abel junction box

Does the iPhone 12 pick up metallic things? For example, paper clips, etc. Planning an upgrade but my line of work sometimes brings my phone (and me) on close proximity to metallic shavings and rust. I’m not keen on a circle of scratched phone!A sheet metal worker specializes in working with thin metal sheets to fabricate, install, and maintain various products and systems. They use blueprints and technical drawings to measure, cut, shape, and join metal sheets using methods like welding, soldering, or riveting.

You'll want to look at article 376 for your trough information and article 312 for pull boxes/ junction boxes. Pull Boxes and Junction Boxes differences between pull boxes in electrical installations. Understand functions, sizes, and applications. A pull box describes an electrical box that gives access to pull electrical cables through non-metallic or metallic raceways and conduit. They give you a means to pull .As a rule of thumb, pull boxes are used when conductors are pulled straight through a box and terminated down-stream. On the other hand, junction boxes can be used for splicing or tapping .

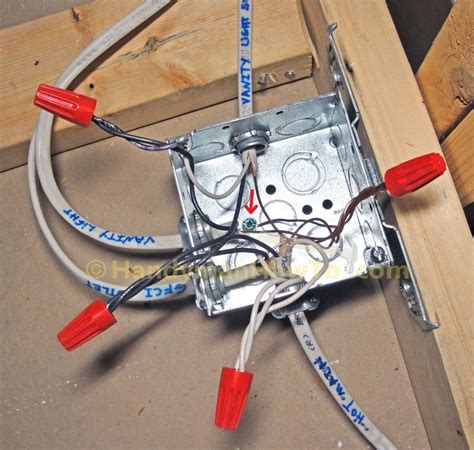

Junction boxes join multiple wires and are used in residential and commercial spaces for organization and code compliance. Choosing the Right Electrical Box for Your Project. Selecting the appropriate electrical box . You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and . The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG . A junction box is a standard electrical box that encloses wire splices and contains no device (like a receptacle). What is a Type 1 junction box vs. a Type 2 junction box? The type 2 junction box is only for indoor use.

You'll want to look at article 376 for your trough information and article 312 for pull boxes/ junction boxes.Learn the key differences between pull boxes and junction boxes, their functions, and when to use each in electrical installations for safety and efficiency.

junction box wiring diagram

Pull Boxes and Junction Boxes differences between pull boxes in electrical installations. Understand functions, sizes, and applications. A pull box describes an electrical box that gives access to pull electrical cables through non-metallic or metallic raceways and conduit. They give you a means to pull conductors across an extended distance without putting too much tension on the cable or insulation.As a rule of thumb, pull boxes are used when conductors are pulled straight through a box and terminated down-stream. On the other hand, junction boxes can be used for splicing or tapping conductors. Field experience has taught electricians that it is not wise to skimp on the size or number of boxes needed in a run. Junction boxes join multiple wires and are used in residential and commercial spaces for organization and code compliance. Choosing the Right Electrical Box for Your Project. Selecting the appropriate electrical box depends on several factors, including construction, wiring method, devices, location, and safety. Type of Construction

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ).

A junction box is a standard electrical box that encloses wire splices and contains no device (like a receptacle). What is a Type 1 junction box vs. a Type 2 junction box? The type 2 junction box is only for indoor use. An LB (LL, LR, etc) is a valid access point for pulling, all by itself, no need for a junction box instead. In general, if not doing something like changing from cable to wires in conduit, a continuous run is preferable, as it has fewer junctions to potentially fail. You'll want to look at article 376 for your trough information and article 312 for pull boxes/ junction boxes.

Learn the key differences between pull boxes and junction boxes, their functions, and when to use each in electrical installations for safety and efficiency. Pull Boxes and Junction Boxes differences between pull boxes in electrical installations. Understand functions, sizes, and applications. A pull box describes an electrical box that gives access to pull electrical cables through non-metallic or metallic raceways and conduit. They give you a means to pull conductors across an extended distance without putting too much tension on the cable or insulation.

As a rule of thumb, pull boxes are used when conductors are pulled straight through a box and terminated down-stream. On the other hand, junction boxes can be used for splicing or tapping conductors. Field experience has taught electricians that it is not wise to skimp on the size or number of boxes needed in a run. Junction boxes join multiple wires and are used in residential and commercial spaces for organization and code compliance. Choosing the Right Electrical Box for Your Project. Selecting the appropriate electrical box depends on several factors, including construction, wiring method, devices, location, and safety. Type of Construction

junction box vs electrical box

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ).

A junction box is a standard electrical box that encloses wire splices and contains no device (like a receptacle). What is a Type 1 junction box vs. a Type 2 junction box? The type 2 junction box is only for indoor use.

electrical pull boxes

electrical junction box vs pull box

Because sheet metal is a relatively basic and straightforward product, with most variations coming from the gauge (thickness) and material, the general process for making it is also straightforward. The 4 primary steps are the melting of your chosen material, pouring it into a rectangular mold, pickling (removing impurities), and rolling and .

electrical trough vs junction box|electrical junction box sizes