typical sheet metal weld symbols Welding symbols are the integral part and the basic requirements for fabrication as they provide vital information for the welding joint location, weld size (throat or leg length, depth of penetration) & length, weld type & quality . Description: Sheet metal refers to metal formed into thin, flat pieces. It’s versatile and can be easily manipulated through cutting, bending, and shaping processes. Pros: Affordable, .

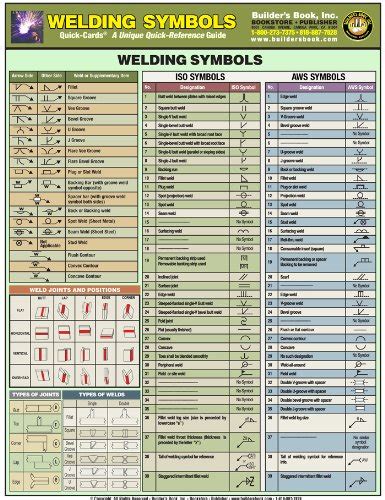

0 · welding symbols quick card pdf

1 · welding chart pdf

2 · weld symbols cheat sheet

3 · weld symbol cheat sheet pdf

4 · printable weld symbol chart

5 · free printable welding symbols

6 · aws 2.4 weld symbols pdf

7 · asme weld symbol chart pdf

There are a dizzying array of electrical box types on the market. But don’t worry: Most electrical boxes fall into nine main types, specializing in a load rating tailored to specific tasks and electric appliances.

Welding symbols are the integral part and the basic requirements for fabrication as they provide vital information for the welding joint location, weld size (throat or leg length, depth of penetration) & length, weld type & quality . The Welding symbols are specified in the ANSI/AWS A2.4 standard. Thie standard also covers brazing and non-destructive symbols & their uses. Welding symbols for fillet, . / Deciphering Weld Symbols. How To Read Weld Symbols. Print Article. Share. Learn how to read common welding symbols and their meaning. Common weld symbols and their meanings. A set of symbols are shorthand .Name Double sided V butt Double sided bevel butt Double sided U butt weld Symbol. Name Fillet Resistance Spot Resistance Steam. Name Finish Weld Symbol on Symbol base platform .

Welding symbol cheat sheet. I recently came across an excellent infographic that clearly explains common weld symbols and their meanings. A few examples: Fillet Weld Symbol. For fillet welds, a triangular symbol shows the weld’s .

A welding symbol can be a pretty complex drawing that consists of basic weld symbols and supplementary symbols, numbers, and letters that can define every single aspect of a specified weld. Therefore, you can get a weld symbol that .

Understand welding symbols used in metal fabrication. Learn to interpret blueprint signs and charts for flawless project execution.

As stated earlier, Weld Symbol is a term used explicitly to designate a specific type of weld.The pertinent types of welds considered under the governing AWS A 2.4 specification for ‘Symbols for welding, brazing and . Weld symbols are shorthand for describing weld type, size & other processing information. These symbols indicate processes used in metal joining operations. . In the production of sheet metal components, spot welding is .

Welding Symbols that can be used when drawing sheet metal fabrications. There are occasions when simply saying weld here or corners to be welded doesn’t fully explain what may be important to you for your sheet metal fabrication design. .Weld metal is deposited in a corner formed by the fit-up of the two members and penetrates and fuses with the base metal to form the joint. The fillet weld symbol is one of the most widely used symbols and the shape placed on the reference line to indicate a fillet weld is a triangle that resembles the side profile of a fillet weld.

For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm).

Dimensional accuracy, tolerance specifications, material specifications, surface finish, and welding symbols are five key metrics in sheet metal fabrication drawings, important for high standard product quality. These metrics reduce errors and improve production efficiency. They serve as a guideline for quality assurance in design and . A Guide to Welders About Welding Symbols Introduction Welding is an intricate craft, blending both art and science. . These welds are typically used in sheet metal work and automotive industries. 6. Spot Weld Symbol. Spot welds are used to join two or more overlapping pieces of material at specific points. The symbol for a spot weld is a .Weld Symbol on Symbol base platform weld . Consumable insert entirely around Symbol on base platform weld . Name Weld between points Weld on site Staggered Symbol Symbol on base platform NO . Title: An Explanation of the Basic Welding Symbols (With Charts) - .

ASME Y14.5 is an established, widely used GD&T standard containing all the necessary information for a comprehensive GD&T system. This article provides an in-depth look at of the contents, history, and purpose of the standard. The most common type of weld is the butt weld, which joins two pieces of metal at their ends. A lap joint weld joins two pieces of metal that overlap each other, while a T-joint weld joins two pieces of metal at right angles to each other. Other types of welds include the corner weld, the edge weld, and the slot weld. During metal joining processes, weld symbols are meant to indicate different parts of the process. These symbols are usually found in fabrication and engineering drawings. . which means that you can apply it with a resistance spot welder used in sheet metal work. Single-U Butt Weld. This is one of the types of single-sided butt welds, and the .

This is the correction to the Welding Symbol Chart for AWS A2.4-98, pages 106 and 107. AWS A2.4-98 Standards Symbols for Welding Bracing and Nondestructive Examination Page 106 AWS A2.4-98 Standards Symbols for Welding Bracing and Nondestructive Examination Page 107 What is drawn? A chart of the basic welding symbols and their location . The design of a welded joint is not an easy job, and often an improperly designed joint can lead to a poorly constructed product.. The word weld is a term that refers to the welding process and the kind of weld joint filler metal, heat-affected zone and material temper, porosity shrinkage, distortion structural integrity, etc. . The majority of all of the above terms and . In below figure, welding symbol for partially filled plug weld is shown. Here, 1/2 is the hole diameter, 1/8 is the depth of plug weld and 45 is the angle of weld preparation for countersunk plug weld hole. . Plug Weld Design for sheet metal and thick steel. A plug weld under stresses shear parallel to its faying surfaces and lead to failure .Groove Weld Symbols Groove weld symbols specify the groove geometry to be welded, and let the welder know what to expect when preparing to weld the weldment. The most common groove weld symbol encountered is the bevel .

Sheet Metal: Simulation: SimulationXpress: Sketching: SLDXML Data Exchange: SOLIDWORKS Sustainability: Tolerancing: TolAnalyst: Toolbox: SOLIDWORKS Utilities . Troubleshooting: Glossary: Weld Symbols. You can use the Weld Symbol tool to add weld symbols to assemblies, drawings, vertices, and edges or faces of parts. The software supports ANSI .Society: ANSI/AWS A2.4, Symbols for Welding and Nondestructive Testing. The structure of the welding symbol The horizontal line--called the reference line--is the anchor to which all the other welding symbols are tied. The instructions for making the weld are strung along the reference line. Weld symbols play a crucial role in sheet metal fabrication, enabling effective communication between designers and welders. . Shown as a triangle-shaped symbol, it is used to represent a weld made in the corner formed by two pieces of metal. Edge Weld: This symbol is used to represent a weld made along the edge of a joint, such as when .Study with Quizlet and memorize flashcards containing terms like The edge weld symbol has many of the elements applied to other weld symbols—size, length, pitch, weld-all-around, weld-in-field, finishing and methods of finishing welds., Dimensions that may be added to the edge weld symbol are size, length, and spacing (pitch of intermittent welds)., The edge weld symbol may .

Welding symbol cheat sheet. I recently came across an excellent infographic that clearly explains common weld symbols and their meanings. A few examples: . Represents a plug weld, which is a weld made by filling a hole with weld metal. Example: Seam Weld Symbol. Description: Represents a seam weld, which is a continuous weld along the length . Part 3: video about welding inspection educationIt covers topics below-weld joints-welding symbol-welding symbol elements-use of each elements of welding sym.

3.2 Welding symbols shall be in accordance with ANSI/AWS A2.4. Fabricator’s drawings shall show the appropriate welding symbol for the particular joint, and the size of weld and the filler metal that is to be used. 3.3 Any deviation from the methods shown shall be approved by SABIC prior to the start of fabrication. 4.

Edge Weld Symbol. The edge weld is a specialized weld that has limited fields of application and is mostly used for the joining of sheet metal components, but it can also be used to join the edges of thin tubes. These welds can be used on a minimum of two sheets being welded on their edge or can be used with multiple sheet metals.4. Other nonstructural sheet metal applications This code covers sheet metal up to and including 6.4 mm [0.250 in]. Also covered are the attachment of accessories and components of the system, and joining or attachment of any member, regardless of thic kness, whose sole purpose is stiffening, supporting, or reinforcing the sheet metal.2. 2D WELD SYMBOLS . Note: Symbols shown above are typical for all welded joints of similar construction unless otherwise specified. 1.1 Engineering Specification for Weld Callouts . Base Metal Thickness (T) in Inches Minimum Size of Groove/Bevel Weld . 0.250 in < T ≤ 0.500 in.Weld symbols indicate the type of preparation to use or the weld type. However, there may still be occasions where other information is required. The basic information can therefore be added to in order to provide further details as shown in Figs.13, 14 and 15. The tail of the weld symbol is the place for supplementary information on the weld.

Typical: .99 .99. .65 delivery Jul 15 - Aug 2 . . Wire/Metal Sheet Thickness Gauge 229895 Welding Gage Plated Size Inspection Tool [NOT Cheap Stamping Version] . Welders Knowledge Posters American Welding Society Welding Symbols Metal Signs Room Home Club Decor Retro Plaque Wall Decor 8x12 Inch Vintage Metal Tin Sign.

switzerland:cnc machining parts contact

Stand and spring-like stainless steel are the two categories used in sheet metal fabrication. Standard stainless can be non-magnetic; any of the 300 series steels are the most commonly used type of stainless. It does not require hot work or other stress relief during manufacturing.

typical sheet metal weld symbols|aws 2.4 weld symbols pdf