types of cnc grinding machine The most common types of CNC grinders are surface grinders, cylindrical grinders, precision ID & OD grinders, and centerless grinders. See more Your premier local supplier for custom and stock sheet metal roofing products. We carry an assortment of stock flashing, scuppers and vents. Plus, we specialize in custom products. Our products are made to last. Scupper and jack joints are fully soldered and water tight.

0 · micromatic cylindrical grinding machine

1 · external cylindrical grinding machine

2 · cylindrical grinding machine manufacturers

3 · cnc internal grinding machine

4 · cnc grinding machine specifications

5 · cnc grinding machine manufacturers

6 · cnc end mill grinding machine

7 · cnc cylindrical grinding machine price

Steel - Powder-coated and stainless steel are often used for a wheel storage box, an under-body or underside box, or a low profile box for the bed or trailer of a truck. What types of truck toolboxes are there? Cross bed - A cross bed truck toolbox extends from one side of .

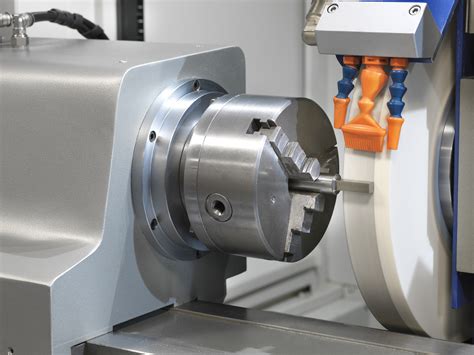

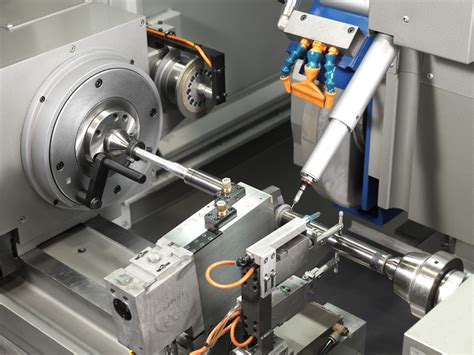

A CNC grinding machine uses a rotating grinding wheel to remove small amounts of material from a workpiece. They are, first and foremost, finishing machines. In the case of round work, a machinist often removes significant amounts of material using a lathe before transferring the part to a cylindrical grinding machine . See moreThe most common types of CNC grinders are surface grinders, cylindrical grinders, precision ID & OD grinders, and centerless grinders. See moreA lot! Studer and Okuma, two respected names in CNC grinding, sell new cylindrical grinders for 0,000 up to the one to two million . See moreThe CNC grinding machine consists primarily of the grinding spindle head holding the workpiece while the grinding wheel removes material from the lateral sides or the front. It’s possible to create various shapes on the part, including flat surfaces, steps, . See more

CNC grinding machines come in various types, each designed to meet specific grinding needs and applications. Some of the most popular grinding machine types include: Surface Grinding Machines. Surface grinding . CNC grinding machines or grinders are not the direct type of CNC machine that cuts or shapes the work, instead, it is used to make dimensions accurate and achieve smooth .

Table 3: Essential Components. Advantages of CNC Grinding Machines. Benefits: CNC grinding machines offer several advantages, including precision, efficiency, and . What are The Types of CNC Grinding. Surface Grinding: This process utilizes a rotating grinding wheel composed of abrasive particles to refine the flat surface of metallic or nonmetallic materials meticulously. It aims to . From creating intricate designs to heavy-duty cutting, there's a CNC machine tailored for every application. There are 15 types of CNC machines that are commonly used in manufacturing operations. Learn about each . Updated September 26, 2024. Learn more about the different types of CNC machines and how they are used in manufacturing. What is a CNC machine? A CNC machine is a programmable machine that can .

Guides to Different Types of CNC Grinding Machine: Advantage and Use. Updated: June 28, 2024. Basketball team Memphis Grizzles uses ‘Grit and Grind’ as their teambuilding concept. The choice of ‘Grind’ comes from . There are seven main types of CNC machines: milling machines, lathes, routers, plasma cutters, laser cutting machines, drilling machines, and grinding machines. CNC technology combines computer control with . The history of CNC grinding traces back to the mid-20th century when advancements in computer technology began to intersect with traditional machining methods.. In the 1950s and 1960s, early computer numerical . The 4 Types of CNC Grinding . Ripley Machine & Tool is a CNC machine shop in Ripley, New York. We specialize in a range of different CNC machining processes, including grinding.We have an experienced grinding .

TYPES OF GRINDING MACHINES 3.1 Floor or bench grinder: A floor or bench grinder is a tiny machine used in laboratories to grind a small workpiece. For example, when we make a single-point cutting . 3.8 Tool And Cutter Grinder A CNC machine tool with up to 5 axes and several grinding wheels is used in a tool and cutter grinder. Sharpening and .

micromatic cylindrical grinding machine

external cylindrical grinding machine

CNC grinding machines carry out the process automatically with precision. 7 Main Types of Grinding Machines. There are seven different types of grinding machines, which are as follows: Surface Grinders. Surface grinders are meant to grind flat surfaces with high precision. It has an abrasive wheel and a chuck, which allows fixing the components . Grinding machines. Whereas the other types of CNC machines listed here are primarily used to make cuts into a workpiece, the primary application of grinding machines is to create a fine finish. A wide array of CNC grinding machines exist, each serving a distinct purpose.

Types of CNC machines: 1. CNC Mills: These machining centers use computer controls to cut different materials. They are able to translate programs consisting of specific number and letters to move the spindle to various locations and depths. Used to make 3D prototypes, moulds, cutting dies, printing plates and sights. . Types and Methods .

A CNC grinding machine uses abrasive tools to achieve a smooth and precise finish on machined products. It is commonly used for components like transmission shafts, camshafts, ball bearings, and other workpieces that require an accurate and polished surface. . The type of CNC machine required largely depends on the nature of the work being .CNC machines that are grinding trusted in the production industry for shaping, grinding and metal that is polishing other materials. Additionally, experience the power and elegance of YUHUAN's product, including high-precision CNC Surface Grinding Machine for metal.A choice of a mixture this is certainly wide of grinding machines has revolutionized the industry, enabling .The CNC grinding machine, combined with the computerized technology, is able to achieve a variety of product geometries by the various types of grinding wheels, which are all maneuvered automatically according to the numerical instructions.

Cylindrical grinding machines are often used for manufacturing parts with tight tolerances and cylindrical shapes, such as shafts, rods, and bearings. 3) Centerless Grinding Machine: In this type of grinding machine, the workpiece is supported between two wheels, one grinding wheel, and one regulating wheel.1. Grinding CNC Machine: ( Types of CNC Machine ) Grinding CNC machines are precision performance tool which use a rotating wheel for cutting the metal away from metal. Generally Grinding CNC machines were used for ball bearings, camshafts, transmission shafts and several of other working pieces which need a correct and accurate finish. Modern grinding machines range from simple manual types to highly automated metal CNC machines, offering flexible solutions for various manufacturing needs. What are the Technical Parameters of Grinding? The technical specifications in grinding are crucial for achieving the desired precision, surface finish, and efficiency.

ATC is utilized to change the cutting tool type in a CNC machine or to substitute a damaged or worn-out cutting tool. It enhances the manufacturing process’s degree of automation. Types of CNC Machines According to the Number of Axes. The types of CNC machines can be further segmented according to the number of axes. Here are some common types: There are 15 types of CNC machines that are commonly used in manufacturing operations. Learn about each type and how they are used here. . CNC Grinding Machines. Precision and finish are the realms of CNC grinding .The grinding machine uses an abrasive wheel to remove material from a workpiece, creating a smooth surface finish and high precision. Types of Grinding Machines. Surface Grinder: For flat surfaces. Cylindrical Grinder: For .

Here are some important details about CNC grinding machines: Explanation of CNC Grinding Machines. CNC grinding machines remove material from a workpiece using an abrasive wheel or belt. The machine's computer . CNC machine tools: These are devices or tools that enhance the performance, convenience, and safety of your CNC machine.They can help you with measuring, cutting, engraving, sanding, and more. Types of tools: There are different types of tools for different CNC machines and purposes.Some of the most common and useful tools are bits, end mills, face . 5. INTRODUCTION 5 • A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding, which is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel's surface cuts a small chip from the work piece via shear deformation. • Grinding is used to finish work pieces that must . 8. Types of Grinding | 1: Surface Grinder The surface grinding machine is used for grinding flat surfaces. The workpiece is supported on a rectangular table which moves back and forth and reciprocates beneath the grinding wheel. A surface grinder consists of an abrasive wheel, a chuck (a workpiece holding device), and a rotary table. The chuck is used to hold the .

Types of CNC Machines in the Market. CNC machines can be classified in various ways including design and function, number of axes, and the control system. . CNC grinding machines are of great value in selections like high precision-gear, auto parts, medically related, aerospace parts, and similar tooling.

Cylindrical objects are often produced with a CNC grinding machine. A grinding machine can also make other types of parts. “CNC” stands for Computer Numerical Control in CNC Grinding Machines. CNC Laser Cutting Machine Grinding Methods: CNC grinding machines employ various methods such as surface grinding for flat surfaces, cylindrical grinding for round objects, and centerless grinding for continuous production. These machines use abrasive wheels to precisely shape and finish materials, ensuring high surface quality and dimensional accuracy. This is a small grinder operated with electric power. It can be easily carried anywhere. Grinding can be done by holding it in hand. It is used for cleaning heavy welding jobs.. On one end of the motor shaft, a grinding wheel is fitted and on the other end, a handle or switch for operating the machine is fixed according to our convenience. It describes how CNC machines are automated machine tools controlled by programmed commands stored on a computer. The history of CNC is outlined from its origins in the 1950s to become widely used today. The main types of CNC machines are identified as turning centers, milling centers, vertical machining centers, horizontal machining centers .

2. Lathe CNC Machine. The way CNC lathe machines operate is by rotating the material of the workpiece about a primary axis. The lathe cutting tools remove the material from the workpiece and shape it as needed.. CNC lathe machines are perfect for various tasks, including swiss machining, drilling, knurling, turning, and sanding.CNC machines in this . There are different types of CNC grinder machines available, each designed for specific grinding operations. The choice of the machine depends on the type of workpiece and the required precision. Whether it is a surface grinder, cylindrical grinder, centerless grinder, tool and cutter grinder, or jig grinder, CNC grinder machines have become an .

cylindrical grinding machine manufacturers

china custom metal fabrication for england quotes

While most pickup truck tool boxes are built from diamond-plate aluminum, these days, some are made from powder-coated steel or even plastic. Boxes can be basic, polished aluminum or may come factory powder coated in matte or gloss black or white, depending on the manufacturer.

types of cnc grinding machine|cnc cylindrical grinding machine price