cnc cut part without damaging bed In order to avoid movement, you should follow these steps:

Struggling to source CNC parts? Explore THECNCSOURCE.COM for easy access to top brands like Renishaw, Blum, Heidenhain, Acu-Rite, Zebra Skimmers and more.

0 · The Ultimate Guide To CNC Router Vacuum Tables

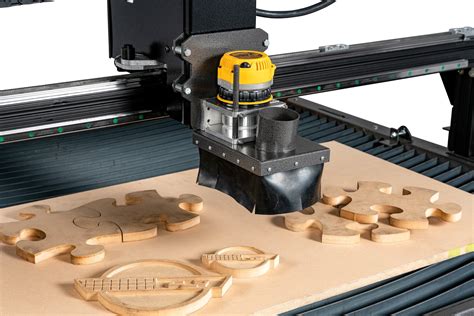

1 · Cutting Small Parts on a CNC Routing Table

Shop our selection of spindles, motors, belts, and more to find the perfect parts for your CNC mills and lathes. Keep your machinery in top condition without breaking the bank. Our parts come with an extended warranty, are two-to-three-times cheaper than OEM parts, and ship as fast as overnight. Looking for a part?Struggling to source CNC parts? Explore THECNCSOURCE.COM for easy access to top brands like Renishaw, Blum, Heidenhain, Acu-Rite, Zebra Skimmers and more.

Some reasons your small parts might be moving. The sacrificial bed is a sheet of material that is situated on top of the vacuum deck. Usually made of medium .Fixture plates offer the highest holding power and is exceptionally good for and CNC creator who has a CNC business, and makes many of the same projects repeatedly. They allow for customized layouts and can handle complete cut .Some reasons your small parts might be moving. The sacrificial bed is a sheet of material that is situated on top of the vacuum deck. Usually made of medium density fiberboard (M.D.F.), it allows the tooling to cut through the part entirely without damaging the deck.Fixture plates offer the highest holding power and is exceptionally good for and CNC creator who has a CNC business, and makes many of the same projects repeatedly. They allow for customized layouts and can handle complete cut-throughs without damaging the vacuum table.

In order to avoid movement you should follow these steps: Replace or skim your sacrificial bed. Close any redundant vacuum zones and cover any exposed areas in the required zone. This will concentrate your vacuum directly on the part that requires cutting. Ensure the surface of the sacrificial bed is clean and free of debris. In order to avoid movement, you should follow these steps: Vacuum Table Tops can be ordered in the standard hole size (right) or in the dense hole pattern (left) which is designed to hold particularly small parts without having them fling off the table when they’re milled free of the sheet material. Here are a few suggestions for cutting small parts safely and without sacrificing productivity: Some reasons your small parts might be moving

Smaller parts can be difficult to hold securely with vacuum because they have less surface area. In this article, I’m going to share how I concentrated the suction from my CNC’s vacuum table to hold parts that would otherwise slide out of place while being cut.In this post, I’ll discuss seven proven methods to hold your workpiece so you can cut it accurately. I’ll introduce each method, then summarize the pros and cons of each. Top Clamping. A common and simple way to hold down a piece is with slotted clamps. You simply place the clamp on top of the workpiece then put the clamp screw through the slot. There are a variety of ways to hold material in place while machining it with a CNC router. In this blog post, we will discuss 8 different methods. Each has its own set of pros and cons, so you will need to choose the one that best suits your needs.

There are times when I find it desirable to machine a piece without using holding tabs to keep all the parts in place. I started doing this 5 years ago and over time have refined the technique and defined the rules that I observe when doing this. The Rules! You must use a 1/8 or 3mm down cutting spiral router bit.Some reasons your small parts might be moving. The sacrificial bed is a sheet of material that is situated on top of the vacuum deck. Usually made of medium density fiberboard (M.D.F.), it allows the tooling to cut through the part entirely without damaging the deck.Fixture plates offer the highest holding power and is exceptionally good for and CNC creator who has a CNC business, and makes many of the same projects repeatedly. They allow for customized layouts and can handle complete cut-throughs without damaging the vacuum table.

In order to avoid movement you should follow these steps: Replace or skim your sacrificial bed. Close any redundant vacuum zones and cover any exposed areas in the required zone. This will concentrate your vacuum directly on the part that requires cutting. Ensure the surface of the sacrificial bed is clean and free of debris. In order to avoid movement, you should follow these steps: Vacuum Table Tops can be ordered in the standard hole size (right) or in the dense hole pattern (left) which is designed to hold particularly small parts without having them fling off the table when they’re milled free of the sheet material. Here are a few suggestions for cutting small parts safely and without sacrificing productivity: Some reasons your small parts might be moving

The Ultimate Guide To CNC Router Vacuum Tables

Smaller parts can be difficult to hold securely with vacuum because they have less surface area. In this article, I’m going to share how I concentrated the suction from my CNC’s vacuum table to hold parts that would otherwise slide out of place while being cut.In this post, I’ll discuss seven proven methods to hold your workpiece so you can cut it accurately. I’ll introduce each method, then summarize the pros and cons of each. Top Clamping. A common and simple way to hold down a piece is with slotted clamps. You simply place the clamp on top of the workpiece then put the clamp screw through the slot. There are a variety of ways to hold material in place while machining it with a CNC router. In this blog post, we will discuss 8 different methods. Each has its own set of pros and cons, so you will need to choose the one that best suits your needs.

how much to move electric fuse box

Cutting Small Parts on a CNC Routing Table

Get instant quotes on custom metal and plastic machined parts with our Online CNC Machining Service. Make quick turn prototypes and production parts in days with free standard shipping on all US orders.

cnc cut part without damaging bed|The Ultimate Guide To CNC Router Vacuum Tables