how to make a plugin to a junction box How to Splice Into an Electrical Receptacle to Add a Second Outlet. Remodeling or updating your homes electrical components can be challenging, yet rewarding. Knowing how .

The online metal weight calculator allows you to calculate the weight of common metals, such as mild steel, carbon steel, stainless steel, aluminum alloy, copper, brass, etc.; Metal shapes include metal plate, metal sheet, metal bar, round .

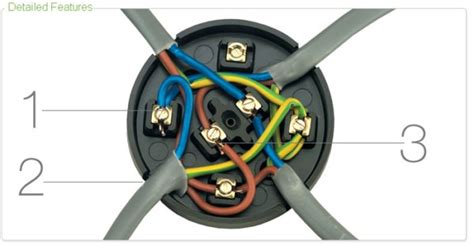

0 · wiring a junction box diagram

1 · terminal junction box wiring guide

2 · junction box wiring problems

3 · junction box wiring instructions

4 · electrical junction box instructions

5 · connecting wires in junction box

6 · 6 terminal junction box wiring

7 · 3 terminal junction box wiring

MIG is the ideal method for welding a 20-gauge metal sheet. The process is fast and simple to use. The only downside is you cannot use it for outside welding as the wind can easily blow out your shielding gas.

During remodeling projects, you may need to convert an existing plug-in outlet into a junction box, perhaps if you're going to build cabinets or closets in the area. You must keep the junction box cover accessible, but it's dangerous to simply leave an outlet in a place difficult to .Disconnect the electricity to the 220-volt switch at the circuit breaker box. Find .Step 1. Purchase a receptalce and a receptacle cover (round or rectangle . For instance, the best way to conceal such a junction box is to use a large, deep 4-11/16" square metal box (which you need for the cubic inches), then stick a 2-gang "mud ring" on it, then stick plain 120V receptacles or switches .

My new garage door opener has a plug at the end. I got a round single outlet at my local electrical supply place, but they did not have a .

How to Splice Into an Electrical Receptacle to Add a Second Outlet. Remodeling or updating your homes electrical components can be challenging, yet rewarding. Knowing how . A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings.

If you have lap siding (wood, hardboard, fiber cement) or plywood sheathing, mount the junction box to the house, using exterior-grade fasteners. Simply drive galvanized deck screws through the mounting lugs. For brick or . If your house has visible wiring splices or if you need to add a new splice to extend a circuit, follow these simple steps to install a junction box.

wiring a junction box diagram

One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely . Step 1. Turn off the power to the existing outdoor outlet at the main service panel. Step 2. Loosen and remove the screws and cover plate over the existing outlet, using the . Part of this will be converting the range to a 4-wire plug. Ranges and dryers can be easily converted from one to the other, but you must follow the instructions (available on the web) to properly remove the neutral-ground .

Install junction boxes properlyKreg pocket hole jig: https://amzn.to/3R8XbO8Milwaukee M12 power screwdriver: https://amzn.to/4bMei0a(affiliate links)Video on.

Electrical wiring

Junction box: Depending on your needs, opt for either a single gang or double gang box. . Plug the transmitter into an outlet of the circuit you want to trace, then use the receiver to identify the correct breaker. Take note of other devices or lighting fixtures on the same circuit. Overloading can be a concern, especially in older homes or . Mounting the Junction Box. Choose an appropriate location for the junction box, making sure it’s easily accessible. Securely mount the box to the wall or ceiling using appropriate screws. Ensure that it’s flush and level for a neat and professional appearance. Connecting Wires Inside the Junction Box Make sure the screws are tight enough to keep the box's cover firmly in place and that the wires inside the box are still secure. Connecting three wires in a junction box may seem intimidating at first, but with the right tools and safety measures, it can be accomplished easily. With some careful preparation and following the steps outlined . A new junction box is used to create wire connections, called splices, in the home. Junction box wiring is often attached to electrical outlet or light fixture wiring. By making the splice in the junction box, the risk of electrical fires occurring from the connected wires coming into contact with flammable materials lessens greatly.

In this video I demonstrate how to add a plug to a circuit using junction boxes. Junction boxes must be accessible at all times, you can use different types .Junction boxes also allow for easy access to the connections, making it convenient to troubleshoot or add new fixtures to the lighting circuit. In conclusion, a junction box is an essential component in electrical systems, providing a safe and organized space for electrical connections. Student training aid for practical skills how to cut a hole in a surface plastic electrical box so a cable can enter. Includes a full demonstration and the p.Hi Everyone. In this video I'm making a holes. Holes in an electrical boxes. I have 5 different types of electrical boxes . Each is for different application.

It's your choice whether to snake one run of cable or use junction boxes. But you need to have a junction box large enough to take the incoming power cable, a receptacle unit, and two or three branches continuing on. Also, if you use one of the receptacle boxes as a junction box, you need to be sure the box is big enough for the incoming cable . #outlet #electrical #DIYHow install a new outlet using an existing junction box. For parts, you'll need a TR (tamper resistant) outlet (15A for 15A circuit b. A single gang electrical box (one gang box) is where electricians install a switch, plug, or thermostat! We splice wires in the box to carry on power (junction box), or use switch legs to turn a light on or off. You’ll learn about pigtails when splicing, and how to organize wires in an electrical box, too! In this video on how to make up a j box( electrical junction box) properly . there will be multiple tips and tricks throughout the video. The video is all ab.

It Is Important To Ensure That The Box Is Installed So That It Provides a Waterproof Seal Around The Wire Connectors. If You'Re Building Waterproof Aluminum Box, You'Ll Need To Make Sure You'Ve Got The Right .

Once you’ve located a spot, you’ll need to drill a hole in the junction box. The hole size will depend on the size of your junction box. However, a good rule of thumb is to make the hole big enough so the junction box can fit snugly. You’ll now .

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . Given that the box is plastic, you have at least 3 options: Try a slightly larger screw. Fill the mounting hole(s) in the box with epoxy, drill a new hole, and re-mount the outlet. Replace the box. If it were me, I would do number 3. Obviously, make sure the electricity to the outlet is turned off before doing any work. Edit 1 : OP says the box .I tried to install an outlet on existing junction box as below, but failed because it's too small to put in. I have 3 solutions to think. Remove junction caps and put 2 outgoing lines into backstabs and screws, so it works as junction; Buy conduits and extend another box on the top

The Electrical Outlet is an outlet for an electrical grid. When connected to a Generator via cables, this Outlet provides power to all nearby devices that use electricity. The Outlet must be connected to the end of any type of Electrical Cable (e.g. on top of a vertical cable, or on the end of a straight or intersection cable). The following items require electricity to run: Air Conditioner . The box should be snug. You can always make the hole bigger, never smaller. Feed the cables through the built-in cable clamps and insert the box into the hole. The NEC requires at least 1/4-inch of the exterior plastic sheathing to be inside the box. Tighten the locking swing clamps with a screwdriver or drill to snug the box to the drywall.

The plug side of this is for connecting to the back of the dishwasher and the junction box at the end of it is for a hard wired connection. You will not be able to make a hard wired connection without this.The existing wires have very little slack / can't be done easily inside a junction box, plus I didn't have the junction boxes at the time and had a wife that was super anxious to the see the project working, and the breaker back on. She would have flipped if I had to make a run to a store at that point. We POC'd it, so now I'm correcting the issue.Wiring a electric range junction box #6 wire0:00 Intro1:31 Cutting out for outlet boxes4:20 Drilling with a flexible/fish bit13:58 Pulling cable to boxes10:58 Finding power21:17 Wiring receptacles 21:1.

Nothing is more dangerous and aggravating than loose wires in a junction box. In this video you'll learn how to wire junction boxes correctly. You'll also se.

how to measure the thickness of sheet metal

how to mig weld sheet metal on rusted fender

The following formulas are used to calculate the weight of Steel for different shapes: Steel Flat Sheet Weight Formula = \( L \times W \times H \times d \) Steel Round Bar Weight Formula = \( \pi \times \frac{D^2}{4} \times L \times d \)

how to make a plugin to a junction box|wiring a junction box diagram