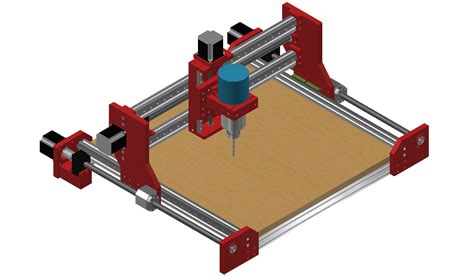

diy 3d printer cnc machine I designed the G300 to be a modular machine, for now I have developed the . Like the fact that some houses, particularly in the northeast, have a five-pointed decorative star hanging on the exterior. It’s been cited as being indicative of everything from religion to a.

0 · diy 3d printer lathe cnc

1 · diy 3d printed cnc router

2 · diy 3d printed Dremel lathe

3 · 3d printer diy lathe milling

4 · 3d printer diy cnc milling

5 · 3d printed cnc router plans

6 · 3d printed cnc mill

7 · 3d printable cnc machine

Simply put, CNC machines use computer-aided design (CAD) and computer-aided manufacturing (CAM) programs to control the movement of cutting tools and workpieces to create nearly any custom shape imaginable.

DIY 3D Printed Dremel CNC: When I got my first 3D printer I was extremely happy with all the new possibilities to create things but after some time I noticed the limitations of 3D printing. .I designed the G300 to be a modular machine, for now I have developed the .Homemade 3 in 1 CNC (Router, 3D Printer & Laser Engraver): This is by far the . I finally built my own CNC Router from scratch by following Ivan Miranda's Tiny CNC Mk. II Design! Huge thanks to PCBWay for sponsoring this video! Check the.

diy 3d printer lathe cnc

diy 3d printed cnc router

I designed the G300 to be a modular machine, for now I have developed the cutter brackets with a diameter of 65mm (for Makita rt0700c, Katsu, etc.) and 52mm (classic 500W spindle with . I just finished my latest big project, building a CNC-machine from scratch using an Arduino Uno and GRBL. I also wrote an extensive and detailed open-source guide of how you can build your own machine!This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.

In this blog post, we will guide you through the process of creating your own CNC machine using 3D printing technology. From selecting the right materials and components to assembling and .

Let's build a CNC machine! Time for an adventure! The PrintNC is a fully open source DIY CNC that offers nearly unbeatable price/performance. Full Disclaimer. How to Build a Custom 3D Printed CNC - DIY Complete BuildOutline: This video highlights how I built a custom 3D printed CNC machine for about 0. This rou. In the Github-Repo you can find the Documentation and CAD files for a large format CNC-machine we build with OpenBuilds parts. Z: 128 cm and weights around 200 kg. .

cleat tool sheet metal

diy 3d printed Dremel lathe

clodbuster metal chassis

DIY 3D Printed Dremel CNC: When I got my first 3D printer I was extremely happy with all the new possibilities to create things but after some time I noticed the limitations of 3D printing. Plastic is easy to melt, sometimes it's not mechanically resistant enough and most imp. I finally built my own CNC Router from scratch by following Ivan Miranda's Tiny CNC Mk. II Design! Huge thanks to PCBWay for sponsoring this video! Check the.I designed the G300 to be a modular machine, for now I have developed the cutter brackets with a diameter of 65mm (for Makita rt0700c, Katsu, etc.) and 52mm (classic 500W spindle with ER11 collet). It can be easily adapted, by printing a specific .Homemade 3 in 1 CNC (Router, 3D Printer & Laser Engraver): This is by far the most longest-running build I have ever made and some improvement always left here and there. But overall said that the machine is running fine without giving any trouble.

I just finished my latest big project, building a CNC-machine from scratch using an Arduino Uno and GRBL. I also wrote an extensive and detailed open-source guide of how you can build your own machine!

This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.In this blog post, we will guide you through the process of creating your own CNC machine using 3D printing technology. From selecting the right materials and components to assembling and calibrating the machine, we will cover all the essential steps.Let's build a CNC machine! Time for an adventure! The PrintNC is a fully open source DIY CNC that offers nearly unbeatable price/performance. Full Disclaimer.

How to Build a Custom 3D Printed CNC - DIY Complete BuildOutline: This video highlights how I built a custom 3D printed CNC machine for about 0. This rou. In the Github-Repo you can find the Documentation and CAD files for a large format CNC-machine we build with OpenBuilds parts. Z: 128 cm and weights around 200 kg. For further information you should take a look in the CNC-OpenBuilds.pdf file! CAD-files: contains CAD-files (who would have thought).DIY 3D Printed Dremel CNC: When I got my first 3D printer I was extremely happy with all the new possibilities to create things but after some time I noticed the limitations of 3D printing. Plastic is easy to melt, sometimes it's not mechanically resistant enough and most imp.

3d printer diy lathe milling

I finally built my own CNC Router from scratch by following Ivan Miranda's Tiny CNC Mk. II Design! Huge thanks to PCBWay for sponsoring this video! Check the.

I designed the G300 to be a modular machine, for now I have developed the cutter brackets with a diameter of 65mm (for Makita rt0700c, Katsu, etc.) and 52mm (classic 500W spindle with ER11 collet). It can be easily adapted, by printing a specific .

Homemade 3 in 1 CNC (Router, 3D Printer & Laser Engraver): This is by far the most longest-running build I have ever made and some improvement always left here and there. But overall said that the machine is running fine without giving any trouble.

I just finished my latest big project, building a CNC-machine from scratch using an Arduino Uno and GRBL. I also wrote an extensive and detailed open-source guide of how you can build your own machine!This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.In this blog post, we will guide you through the process of creating your own CNC machine using 3D printing technology. From selecting the right materials and components to assembling and calibrating the machine, we will cover all the essential steps.

Let's build a CNC machine! Time for an adventure! The PrintNC is a fully open source DIY CNC that offers nearly unbeatable price/performance. Full Disclaimer.How to Build a Custom 3D Printed CNC - DIY Complete BuildOutline: This video highlights how I built a custom 3D printed CNC machine for about 0. This rou.

clear cover junction box

Wet Location Protection: Dry-tite™ boxes and covers protect wiring devices, switches, electronic components and terminal blocks in dry, damp and wet locations. Red Dot® boxes are made from durable die-cast aluminum and available in single- and double-gang rectangular as well as round configurations—with a variety of hub sizes to meet all .

diy 3d printer cnc machine|diy 3d printer lathe cnc