cnc machining definitions Definition, Types and Applications. Hey there, I’m Caro! I am the author of this article and a CNC machining specialist at RICHCONN with ten years of experience, and I am happy to share my knowledge and insights with you through this blog. We provide cost-effective machining services from China, you can contact me anytime if you have any . This listing is for an awesome cool retro/vintage 2001 Metal WONDER WOMAN lunchbox. The lunch box is made of tin, and was manufactured by The Tin Box Company back in 2001 (@DC Comics). Overall, this piece is not only super AWESOME, but shows little to no wear and tear.

0 · what is the cnc process

1 · what is cnc in engineering

2 · what is cnc cutting machine

3 · what do cnc machines make

4 · how does cnc machining work

5 · how cnc machine is controlled

6 · cnc machine meaning in english

7 · cnc machine acronym

Tyco Electronic's Non-metallic splice and tap kits provide a fast and reliable method for splicing or tapping 2 wire w/ ground and splicing 3 wire w/ground non-metallic cables up to 300 volts. They are

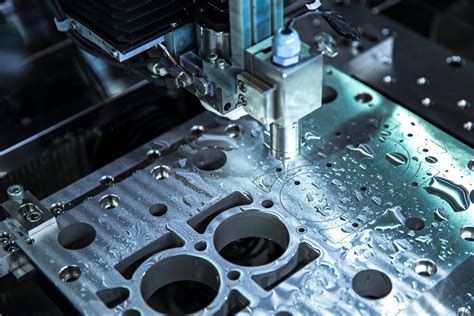

CNC machining basics: CNC stands for Computer Numerical Control and it is a process of using computer software to control the movement and operation of machine tools. CNC machining applications: CNC machines .

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials.; Types of CNC machines: . Definition. CNC machining is a process that involves the automatic control of machine tools through a computer to shape the material into the required form. During this process, machining equipment like latches, routers, . In simple words, the types of CNC machines used to produce parts are such as a CNC lathe, a 3 axis CNC milling machine, or a 5 axis machining centre. However, the parts’ intricacy will regulate which machine part will be suitable for the job, for example, the intricacy, geometry, and dimensions of parts as well as the tolerances, end-use of . Definition, Types and Applications. Hey there, I’m Caro! I am the author of this article and a CNC machining specialist at RICHCONN with ten years of experience, and I am happy to share my knowledge and insights with you through this blog. We provide cost-effective machining services from China, you can contact me anytime if you have any .

CNC machining is a form of precision machining that shapes intricate metal, plastic, and resin parts into products. CNC machinery plays a crucial role in this process by allowing for precise control through pre-programmed software, making it essential for producing a wide range of complex and detailed products across various industries.

CNC Machining: Computer numerical control (CNC) machines offer high precision and repeatability, making them ideal for complex spline profiles and large-scale production. 5-Axis Machining : This advanced technique allows for simultaneous cutting in multiple directions, enabling the production of intricate spline designs with superior accuracy .What is CNC Machining? CNC machining is a type of automated machining process that uses computer numeral control technology to shape an object or a part by removing material from a workpiece until the desired shape is achieved.. CNC stands for Computer Numerical Control. It means utilizing computerized software to control how a machine moves and operates.

china cnc automation parts

what is the cnc process

L'usinage CNC (Computer Numerical Control, en français Commande Numérique par Ordinateur) est une méthode de fabrication industrielle automatisée, qui permet de produire des pièces en métal, en plastique ou en bois, de manière précise et répétitive. Cette technique repose sur l'utilisation de machines-outils commandées par ordinateur, qui permettent de .CNC Machining Definition. CNC machining is a manufacturing process that uses computerized controls to operate and manipulate machine tools to produce precision parts from different materials. It stands for Computer Numerical Control, and .Even if you don’t have in-depth knowledge of manufacturing and machining, you may have heard of a metal lathe. These machines are widely used in machine shops, second only to milling machines in popularity. A CNC lathe machinist may use a lathe CNC machine for sale. If you are a business owner,plant manager, or supervisor responsible [.] CNC Machining Process. CNC machining is an automated method of manufacturing that primarily involves the following four steps: Step 1: Design a CAD model. Create a 3D model of the product using CAD software. Step 2: Convert the CAD file to a CNC program. CNC machines cannot directly read CAD models.

In CNC machining, axis refers to a plane of motion. Most CNC units work using three axes: the x-axis, the y-axis and the z-axis. Box Tool. A box tool is a tool holder that partially surrounds a work piece in an automatic lathe or screw machine, supporting it against the pressure of the cutting tool.. Computer Aided Design Multi-Axis CNC Milling Machine. Multi-axis CNC milling machine can cut at different angles and move along different aces. There are several kinds of multi-axis milling machines: 2-axis milling machines. 2-axis milling machines can work as a workpiece in the x and z axes. Therefore, they can cut vertically and horizontally in one direction.

A 6-axis CNC machine can move in all six linear and rotary axes. 6-axis CNC machines have an extraordinary improvement in machining speeds and accuracy. 6-axis CNC machines are also a further step forward in terms of the precision of the operations. CNC Machining Is Fully Automated. In today’s CNC protocols, the production of parts via pre-programmed software is mostly automated. The dimensions for a given part are set into place with computer-aided design (CAD) software and then converted into an actual finished product with computer-aided manufacturing (CAM) software.

The CNC machining process involves utilizing computer software to program the movement of production equipment and tools. This method is commonly employed to operate complex machinery such as mills, lathes, CNC routers, . Understanding CNC Machining Terms, Definitions and Parameters. A solid understanding of CNC terminology and CNC machining parameters will help you grasp more advanced concepts later on. Here is a .

CNC Precision Machining: Definitions, Tolerances, Equipment, Application Advantages Guide. 09/04/2024 11/04/2024. What is Precision CNC Machining? CNC precision machining is a machining method based on computer numerical control technology. It utilizes pre-programmed computer instructions to control the movement of the machine tool, thereby . How does CNC Machining Work? CNC machining means Computer Numerical Control machining. CNC machining is the magic of high technology. It applies computers to run the machines that produce objects with extreme precision. It is a really great technique to automate the production of customized parts. To turn the CNC machine, you type codes into .With CNC, each object to be manufactured gets a custom computer program, usually written in an international standard language called G-code, stored in and executed by the machine control unit (MCU), a microcomputer attached to the machine. The M-code language is also used in conjunction with G-code in CNC operations.

CNC Machining uses software to render a 3D design into instructions for a set of computer-controlled machining tools. Step into the world where digital creativity meets hands-on precision. CNC machining is more than just a technological marvel; it's a way to turn intricate designs into tangible realities. CNC machining is a subtractive manufacturing technology that automatically removes material from raw stock based on a set of computer-generated instructions. Generally, CNC machines are divided into two types of machines that keep the raw stock stationary and rotate the cutting tool, and machines that rotate the raw stock while moving it . What is CNC Machining: Definition, Operations, Machines & Applications What is Abrasive Machining: Definition, Types & Abrasives Used Different Machining Types: 35 Machining Processes and Operations. Jonathan Schlick. Today’s Techni Waterjet Manufacturing Manager, Jonathan Schlick, has over 20 years experience in the field of industrial .What is milling machine? Milling machines, which have existed for over 300 years, are highly utilized industrial machining tools, renowned for their exceptional quality and speed. Grasping the fundamentals of mill machine offers manufacturers a competitive edge. This article aims to offer a comprehensive understanding of the milling machine’s operational process. You’ll discover .

The CNC machining process offers many advantages because it is automated and uses computer-controlled machine tools to fabricate parts from raw materials. The process can produce many different parts with varying levels of complexity. CNC machining is often used in the aerospace, automotive, and medical industries, where specific parts must meet stringent . Definition: CNC milling is a digital machining process in which the rotary motion of the milling cutter and the movement of the workpiece relative to the milling cutter are controlled by the CNC system on the CNC milling machine or machining center to obtain the desired shape, size and surface quality.CNC Machining Parts: Definition, Benefits, and Design Guide. In today’s world, lathe machined parts are everywhere and it’s easy to see why, mainly because turned parts manufacturers are constantly improving their machining technology. They are an integral part of most machinery as they offer precision and efficiency in an affordable manner.

china cnc auto part

what is cnc in engineering

china cnc car parts factory

what is cnc cutting machine

CarveWright makes innovative CNC systems for all levels of users. Check out our current RAVEN CNC with its feedthrough design.

cnc machining definitions|cnc machine acronym