cnc machine axis acceleration To put it simply, the faster you want to accelerate the axes of your machine, the more motor torque will be needed. Similarly, the bigger the cuts . Each of the watches come with steel and wood bezel rings that you can swap out at will, allowing you to customize the watch exactly the way you want it. It even comes in its own humidor watch box, designed to protect it and put it on .

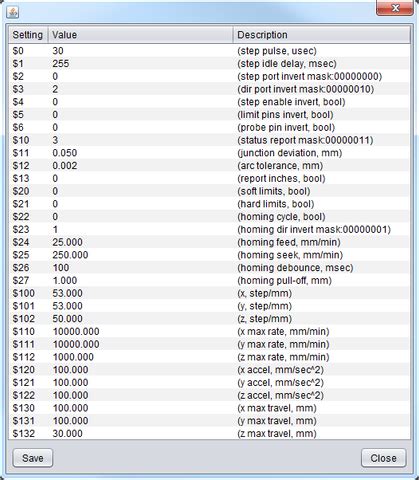

0 · cnc tuning settings

1 · cnc settings for total novice

2 · cnc settings for beginners

3 · cnc mini mill acceleration

4 · cnc for a total novice

5 · cnc adjustment settings

6 · cnc adjustment chart

7 · benchtop mini mill acceleration

Carpenters know how to cut, shape and handle these materials to create a project. Some of their job duties include reading blueprints and collaborating with clients to ensure they construct the project correctly. They also assess the quality of the materials they use and operate machinery and tools. Related: Learn About Being a Carpenter. 5.

The typical CNC lathe or machining center has an acceleration of 0.2g (2 m/sec2). High speed machines have accelerations up to 2g (20 m/sec2). These equations (familiar to anyone who has done any course related to mechanical engineering) enable you to calculate . To put it simply, the faster you want to accelerate the axes of your machine, the more motor torque will be needed. Similarly, the bigger the cuts .

stand up electrical enclosure

30 taper machines like Speedios and Robodrills accelerate at 1.5g (15m/s^2), and that's considered very fast. For your machine, a few newton meters or foot pounds will be . Faster accel can greatly reduce cycle times, especially with 3D carving. One big exception here, is when you reach the limits of your machine's rigidity. Mach3's linear accel . When I looked at the specification from the machine I purchased it should run at 1000mm/s but have found out that I run into problems around 400mm/s. Is 300 mm/s a normal max speed or is that slow? Please let me .

I've been reading the Fanuc manuals to find out how the machine acceleration/deceleration rate is set. Let's just consider the simplest situation, linear .

stainless steel xl litter box

Algorithms are developed to compute the feedrate variation along a curved path, that ensures minimum traversal time for a 3-axis CNC machine subject to both fixed and .Machine Limits. What It Is: Machine limits define the maximum allowable movements for each axis, including speed, distance, and acceleration. Why It’s Important: Understanding machine . The typical CNC lathe or machining center has an acceleration of 0.2g (2 m/sec2). High speed machines have accelerations up to 2g (20 m/sec2). These equations (familiar to anyone who has done any course related to mechanical engineering) enable you to calculate the acceleration time and distance.This sets the axes acceleration parameters in mm/second/second. Simplistically, a lower value makes Grbl ease slower into motion, while a higher value yields tighter moves and reaches the desired feed rates much quicker. Much like the max rate setting, each axis has its own acceleration value and are independent of each other.

standard cold formed steel box beam cad

To put it simply, the faster you want to accelerate the axes of your machine, the more motor torque will be needed. Similarly, the bigger the cuts you want to make, the more cutting forces will be generated, and once again, the bigger the axis stepper or servo you will need.

30 taper machines like Speedios and Robodrills accelerate at 1.5g (15m/s^2), and that's considered very fast. For your machine, a few newton meters or foot pounds will be enough torque. Faster accel can greatly reduce cycle times, especially with 3D carving. One big exception here, is when you reach the limits of your machine's rigidity. Mach3's linear accel and decel can start to get rather violent with really high acceleration settings. When I looked at the specification from the machine I purchased it should run at 1000mm/s but have found out that I run into problems around 400mm/s. Is 300 mm/s a normal max speed or is that slow? Please let me know what . I've been reading the Fanuc manuals to find out how the machine acceleration/deceleration rate is set. Let's just consider the simplest situation, linear accel/decel profile. So far, I came across few things: Time constant for cutting feed, T1; Maximum acceleration for G01, let's call it Amax1.

Algorithms are developed to compute the feedrate variation along a curved path, that ensures minimum traversal time for a 3-axis CNC machine subject to both fixed and speed-dependent axis acceleration bounds arising from the output-torque characteristics of .

Machine Limits. What It Is: Machine limits define the maximum allowable movements for each axis, including speed, distance, and acceleration. Why It’s Important: Understanding machine limits ensures that you operate the CNC machine within safe parameters, preventing overtravel, crashes, and potential damage to the machine or workpiece.

The development of S-curve acceleration and deceleration (ACC/DEC) algorithms has become important for computer numerical control (CNC) machining in recent decades because it provides smoother feed motions for cutting tools and can thus shorten the machining time, maintain the machining quality, and enhance the tool life. In this The typical CNC lathe or machining center has an acceleration of 0.2g (2 m/sec2). High speed machines have accelerations up to 2g (20 m/sec2). These equations (familiar to anyone who has done any course related to mechanical engineering) enable you to calculate the acceleration time and distance.

cnc tuning settings

cnc settings for total novice

This sets the axes acceleration parameters in mm/second/second. Simplistically, a lower value makes Grbl ease slower into motion, while a higher value yields tighter moves and reaches the desired feed rates much quicker. Much like the max rate setting, each axis has its own acceleration value and are independent of each other.To put it simply, the faster you want to accelerate the axes of your machine, the more motor torque will be needed. Similarly, the bigger the cuts you want to make, the more cutting forces will be generated, and once again, the bigger the axis stepper or servo you will need.

30 taper machines like Speedios and Robodrills accelerate at 1.5g (15m/s^2), and that's considered very fast. For your machine, a few newton meters or foot pounds will be enough torque.

cnc settings for beginners

Faster accel can greatly reduce cycle times, especially with 3D carving. One big exception here, is when you reach the limits of your machine's rigidity. Mach3's linear accel and decel can start to get rather violent with really high acceleration settings. When I looked at the specification from the machine I purchased it should run at 1000mm/s but have found out that I run into problems around 400mm/s. Is 300 mm/s a normal max speed or is that slow? Please let me know what . I've been reading the Fanuc manuals to find out how the machine acceleration/deceleration rate is set. Let's just consider the simplest situation, linear accel/decel profile. So far, I came across few things: Time constant for cutting feed, T1; Maximum acceleration for G01, let's call it Amax1.

Algorithms are developed to compute the feedrate variation along a curved path, that ensures minimum traversal time for a 3-axis CNC machine subject to both fixed and speed-dependent axis acceleration bounds arising from the output-torque characteristics of .

Machine Limits. What It Is: Machine limits define the maximum allowable movements for each axis, including speed, distance, and acceleration. Why It’s Important: Understanding machine limits ensures that you operate the CNC machine within safe parameters, preventing overtravel, crashes, and potential damage to the machine or workpiece.

stamping parts sheet metal fabrication for sale

stainless steel.lunch box kids

$5.63

cnc machine axis acceleration|cnc settings for total novice