sheet metal standards ASTM International has been the standards development partner of the metals producing industry for more than a century. Today, thousands of ASTM standards cover both ferrous and . If the value of sheet metal K factor and bending flange length is known. Sheet Metal flat length can be calculated in the following three steps. Step-1: Calculate the value bend allowance for the required sheet metal bend by using the .

0 · standard thicknesses of sheet metal

1 · standard sheet sizes in mm

2 · standard sheet metal size chart

3 · sheet metal types and grades

4 · sheet metal specifications chart

5 · sheet metal guidelines pdf

6 · basics in sheet metal design

7 · 20 gauge sheet metal lowe's

We can determine what the object "2 times (3y+5)" is to begin with by distributing the 2, then once we have determined that that object is [6y+10] we have to take away that ENTIRE object (so we bracket the whole expression there): 8- [ 6y+10 ] = 8-6y-10. It's sometimes helpful to think about it in terms of actual numbers: 8- (3+5) = 8-8 = 0.

SMACNA standards and manuals address all facets of the sheet metal and HVAC industry – including duct construction and installation, indoor air quality, energy recovery, roofing and architectural sheet metal, welding, and commissioning.SMACNA Technical Papers and Guidelines review processes, specifications and .

These steel standards are helpful in guiding metallurgical laboratories and refineries, product manufacturers, and other end-users of steel and its variants in their proper processing and application procedures to ensure quality towards .ASTM International has been the standards development partner of the metals producing industry for more than a century. Today, thousands of ASTM standards cover both ferrous and .Counter sinks – A counter sink can be put in sheet metal by both machining and/or punching. Each of these methods give the finished part different characteristics. The cross sections of . Steel grades & standards. According to the World Steel Association, there are over 3,500 different grades of steel. At its core, steel is composed of iron and carbon, but the amount of carbon, level of impurities, .

standard thicknesses of sheet metal

SMACNA Technical Papers and Guidelines review processes, specifications and requirements in various documents and standards, providing reviews, recommendations, clarifications and some useful tips for contractors.

emeril knife set 5 pcs stainless steel w wooden box

This specification covers hot-rolled and cold-rolled alloy steel sheet and strip. The steel materials shall be melt processed, hot rolled, cold rolled, and heat treated.Basic Principles. Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and .

To achieve the required sheet metal tolerance in sheet metal part design guidelines, manufacturers must use precise machinery during production. ADH has 20 years of experience in world of sheet metal manufacturing .F1267-18(2023) Standard Specification for Metal, Expanded, Steel . A1083/A1083M-23 Standard Specification for Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy, Produced by Twin-Roll Casting Process 5. REQUIREMENTS FOR SHEET METAL PART DRAWINGS Sheet metal parts are typically created from material less than .250 inches thick, and are formed by folding the material at specific locations with a controlled bend radius. See document 10-0005, Blah Drawing & Drafting Standards and Practices , for the proper setup of a sheet metal drawing.

Standard Sheet Metal and Mechanical delivers cost-effective, quality HVAC and sheet metal solutions with a commitment to excellent customer service. Standard Specification for Steel, Sheet and Strip, Alloy, Hot-Rolled and Cold-Rolled, General Requirements for A0505-16R21 ASTM|A0505-16R21|en-US Standard Specification for Steel, Sheet and Strip, Alloy, Hot-Rolled and Cold-Rolled, General Requirements for Standard A505 Standard Specification for Steel, Sheet and Strip, Alloy, Hot-Rolled and . Sheet metal drawing standards seem to hard to come by as I have been searching a little bit lately as well. I understand that bend allowances vary greatly by material, tooling, and process. What I am looking for is standard accepted language or a format for describing information on a flat pattern view. For example, one of our designers has .STANDARD SHEET METAL AND AIR CONDITIONING CONTRACTORS’ . The Sheet Metal and Air Conditioning Contractor’s National Association (“SMACNA”) provides its product for informational purposes. b) The product contains “Data” which is believed by SMACNA to be accurate and correct but the data, including all information, .

Sheet metal fabrication is a crucial process in the manufacturing industry, with numerous applications in construction, automotive, aerospace, and other fields. The versatility of sheet metal and its ability to be formed into various shapes and sizes make it a popular choice for creating complex and intricate designs. Sheet Metal Standards. 1-20 of 2,319 results 20 results per page 10 results per page 30 results per page 50 results per page 100 results per page Filters: Most-Recent Revision Only Clear all. Narrow Your Results Revision. clear. Most-Recent Revision Only (2,319) Not False (0) Publisher. ASTM (178) SMACNA (21) NAVY (1) .Today that is still true as SSM employs people with a wide array of sheet metal experience, on projects around the globe and with different degrees of complexity. Each member of the SSM team brings a unique skill set to the table, working towards solving for .

Although there is a range of standard sheet metal sizes, the most common ones are 36”x 96”, 36”x 120”, 36”x 144”, 48”x 96”, 48”x 120”, and 48”x 144”. While sheet metal thickness/gauge number has a corresponding weight ratio, such as lbs per square foot or kilograms per square metre, sheet metal sizes are not tied to the . Sheet metal is harder to dimension than machined parts primarily because the bending is less accurate. Sheet metal shops tell me they can do ±.015" (0.4mm) from a bend. I would guess that the punching that flat layout approaches the accuracy of machining. You need to do tolerance stacks with your realistic tolerances.

State Apprenticeship Standards. for . Sheet Metal . Revised April 2023. DRAFT. DRAFT . DRAFT. Foreword . The State Committees are a very important part of the structure that advises the Bureau on the administration of the apprenticeship program and on communicating with all the Chantilly, Va. (October 12, 2021) — The Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA), has published the fourth edition of its "HVAC Duct Construction Standards – Metal and Flexible." Building on a history of duct construction standards nearly 100 years old, this fourth edition represents the state of the art in sheet metal duct .York Haven Fabricators, Inc. Workmanship Standards ~ 2 ~ This document is a statement to the quality and workmanship of York Haven Fabricators, Inc., henceforth referred to as YHF. . requirements for sheet metal fabricated by YHF. 2) Scope The intent of this specification is to supplement all engineering drawings, . Drafting Standards, GD&T & Tolerance Analysis . Sheet Metal Part GDT Thread starter nmine; Start date Jun 5, 2024; Status Not open for further replies. Jun 5, 2024 #1 nmine Mechanical. Jul 7, 2023 . I have a large sheet metal enclosure base that has lots of panel mount connector holes. How do you go about applying GDT when one datum setup .

We have the right people, equipment and expertise to custom fabricate any component that can be designed and built of metal from light to heavy gauge sheet metal up to 1-inch-thick steel plate. Over the years, customers return to . You can define this in the sheetmetal standards defined in the sheetmetal parameters option in the sheetmetal design workbench.You can find the info on this in the catia online documentation guide. Upvote 0 Downvote

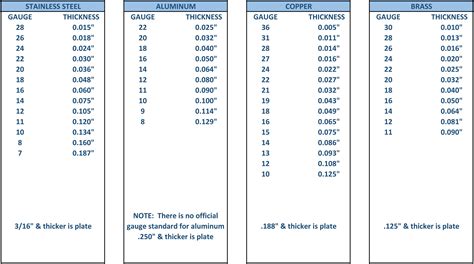

Standards Back. Standards. Law and Regulations ; Federal Registers ; Open for Comment ; Regulatory Agenda ; Standard Interpretations ; Training Requirements by Standard ; . 3444 Sheet Metal Work Establishments primarily engaged in manufacturing sheet metal work for buildings (not including fabrication work done by construction contractors at .Gauge size chart for sheet metal. Filter for standard steel, galvanized steel, stainless steel, zinc, or birmingham gage. Login | Register for free! . Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. The equivalent thicknesses differ for each gauge size . To achieve the best surface finish possible for sheet metal fabricated parts, we recommend sourcing a material that already has a surface finish comparable to the desired finish.Then, we can use one of these standard methods to clean it up even further: Employing our Timesaver Abrasive Belt Finishing Machine to clean up the surfaces of sheet metal fabricated . Sheet Metal Worker 1761 47-2211 0510 000 7,200 hours . MA#: 1277 SOC Title: Sheet Metal Workers License: N/A . . these Standards becomes illegal, as it pertains to federal and/or state law, that part and that part alone will become inoperative and null and void, and the Oregon Bureau of Labor and Industries (BOLI) may .

Japanese Industrial Standards (JIS) are used to define the specifications and testing methods for metal materials in Japan. JIS standards emphasize high precision and quality, making them particularly relevant for industries that demand the highest manufacturing standards, such as electronics and automotive production. Sheet Metal Workmanship Standards. 1-20 of 2,106 results 20 results per page 10 results per page 30 results per page 50 results per page 100 results per page Filters: Most-Recent Revision Only Clear all. Narrow Your Results Revision. clear. Most-Recent Revision Only (2,106) Not False (0) Publisher. CRC (3) AWS (16) .

Various test methods are available to establish the suitability of the sheet metal for the forming processes involved. The hole expanding test is one of the best methods for evaluating the suitability of the sheet metal for forming such “flanges” because it closely resembles the process used under production conditions to form such flanges (plunged rims) starting with punched . An American National Standard . Sheet Metal Welding Code . AWS D9.1/D9.1M:2018 An American National Standard . Approved by the American National Standards Institute . September 29, 2017 . . The AWS Committee on Welding of Sheet Metal was organized in May 1978 and has published six previous versions of D9.1. The 1. st . edition, D9.1-80,Standard Sheet Metal is always looking to bring on new talented members to join our team. Take a look at our career openings and see if there is a position that interests you! Apply Now. quick . contact. Standard sheet metal works, INC. 220 N Commerce Peoria, .

A box spring is a bed base with a wooden frame and either actual springs or metal rods that provide support to a mattress. It is a type of mattress foundation. The box spring is usually the same size as the mattress that sits on it.

sheet metal standards|sheet metal types and grades