cnc lathe machine control What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far .

Incorporate function and durability into your bathroom with our wide selection of well-designed bathroom cabinets and storage solutions at Wickes.

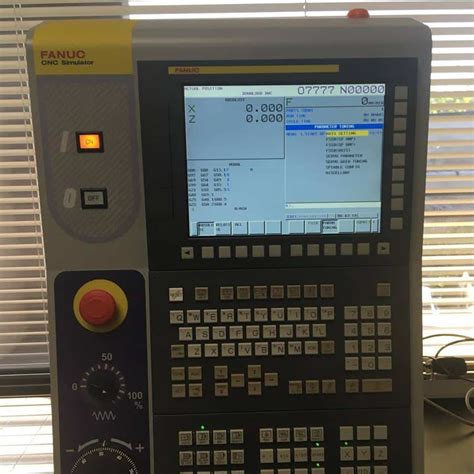

0 · what is FANUC in cnc

1 · pc based cnc control system

2 · hobby cnc controller boards

3 · hobby 5 axis cnc controller

4 · controller for hobby cnc lathe

5 · cnc lathe controller suppliers

6 · best diy cnc controller board

7 · 4 axis cnc controller board

Outdoor WiFi Enclosure, Outdoor Electrical Box Waterproof IP67, 6X6 Inch Waterproof Junction Box ABS Plastic with Hinged Cover, for WiFi Electronics Solar Network Marine Outside

what is FANUC in cnc

What is CNC Lathe Programming? CNC lathe programming is the process of using coded instructions to control a CNC lathe machine. This programming is a critical component of .A CNC lathe uses computer control to automate the machining process. This means it follows pre-programmed instructions for cutting, drilling, and shaping parts. In contrast, a normal lathe . A CNC lathe is a sophisticated machine tool designed for precision CNC turning and manufacturing through Computer Numerical Control (CNC). It’s an embodiment of technological evolution, marrying the age-old principles of a .

A CNC lathe is a sophisticated machine tool designed for precision CNC turning and manufacturing through Computer Numerical Control (CNC). It’s an embodiment of .

pc based cnc control system

hobby cnc controller boards

Ever wondered how CNC machines seamlessly transform raw materials into precise components? This article breaks down the basics of CNC machine operation, from powering up to navigating the control panels. . What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far .CNC lathe machines operate on CNC programming principles, automated tool movement and positioning, material removal process, and precision machining. These principles enable the machine to produce high-quality components .

CNC lathe machines are marvels of modern engineering, designed to perform CNC turning with incredible precision. But how do they work? At the heart of a CNC lathe machine is the concept of computer numerical control. This means the machine’s movements are directed by coded instructions, usually written in G-code.

What is CNC Lathe Programming? CNC lathe programming is the process of using coded instructions to control a CNC lathe machine. This programming is a critical component of modern manufacturing, allowing for the creation of highly precise parts with minimal human intervention. CNC or computer numerical control is an NC system that employs a dedicated microcomputer as a machine control unit. The presence of a microprocessor, RAM, ROM, and input and output devices has increased the level of automation in NC systems.A CNC lathe uses computer control to automate the machining process. This means it follows pre-programmed instructions for cutting, drilling, and shaping parts. In contrast, a normal lathe requires manual operation, where the machinist manually guides the cutting tool.

In this ultimate guide to CNC controllers, I’ll cover everything you need to know about their features, price, and device compatibility, so you can choose a controller you’ll actually be able to use. The best CNC controller for most hobbyists is the CNCTOPBAOS 3 Axis GRBL. A CNC lathe is a sophisticated machine tool designed for precision CNC turning and manufacturing through Computer Numerical Control (CNC). It’s an embodiment of technological evolution, marrying the age-old principles of a lathe machine with advanced computer programming to achieve unprecedented accuracy and efficiency in machining.

direct industry electrical enclosure steel

A CNC lathe is a sophisticated machine tool designed for precision CNC turning and manufacturing through Computer Numerical Control (CNC). It’s an embodiment of technological evolution, marrying the age-old principles of a lathe machine with advanced computer programming to achieve unprecedented accuracy and efficiency in machining.

Ever wondered how CNC machines seamlessly transform raw materials into precise components? This article breaks down the basics of CNC machine operation, from powering up to navigating the control panels. Discover essential functions like program editing, tool setting, and emergency protocols. What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far more functionality than just this though.CNC lathe machines operate on CNC programming principles, automated tool movement and positioning, material removal process, and precision machining. These principles enable the machine to produce high-quality components efficiently with accuracy and consistency.CNC lathe machines are marvels of modern engineering, designed to perform CNC turning with incredible precision. But how do they work? At the heart of a CNC lathe machine is the concept of computer numerical control. This means the machine’s movements are directed by coded instructions, usually written in G-code.

What is CNC Lathe Programming? CNC lathe programming is the process of using coded instructions to control a CNC lathe machine. This programming is a critical component of modern manufacturing, allowing for the creation of highly precise parts with minimal human intervention. CNC or computer numerical control is an NC system that employs a dedicated microcomputer as a machine control unit. The presence of a microprocessor, RAM, ROM, and input and output devices has increased the level of automation in NC systems.

A CNC lathe uses computer control to automate the machining process. This means it follows pre-programmed instructions for cutting, drilling, and shaping parts. In contrast, a normal lathe requires manual operation, where the machinist manually guides the cutting tool. In this ultimate guide to CNC controllers, I’ll cover everything you need to know about their features, price, and device compatibility, so you can choose a controller you’ll actually be able to use. The best CNC controller for most hobbyists is the CNCTOPBAOS 3 Axis GRBL. A CNC lathe is a sophisticated machine tool designed for precision CNC turning and manufacturing through Computer Numerical Control (CNC). It’s an embodiment of technological evolution, marrying the age-old principles of a lathe machine with advanced computer programming to achieve unprecedented accuracy and efficiency in machining.

A CNC lathe is a sophisticated machine tool designed for precision CNC turning and manufacturing through Computer Numerical Control (CNC). It’s an embodiment of technological evolution, marrying the age-old principles of a lathe machine with advanced computer programming to achieve unprecedented accuracy and efficiency in machining.

Ever wondered how CNC machines seamlessly transform raw materials into precise components? This article breaks down the basics of CNC machine operation, from powering up to navigating the control panels. Discover essential functions like program editing, tool setting, and emergency protocols.

What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far more functionality than just this though.

hobby 5 axis cnc controller

Williams Metal Fabrications Pty Ltd. ABN: 12081918381. Business Type: Manufacturing Company. Sub-Industry: Defence, Metal fabrication and primary metal production, Mining, Marine and rail. Primary Location: SA. site: www.williamsmetalfabrications.com.au.com

cnc lathe machine control|what is FANUC in cnc