best way to make sheet metal box Fabricating a sheet metal box can be a rewarding DIY project or a valuable skill for professionals. In this comprehensive guide, we'll walk you through the step-by-step process of creating a sheet metal box, ensuring you have all the information you need to succeed.

Standard sheet metal screws require a pilot hole to be drilled before insertion to prevent splitting within the material. The pilot hole drill bit size depends on the size of the sheet .

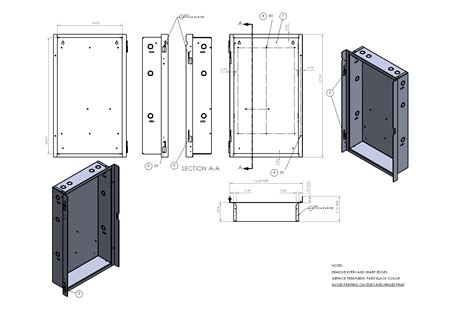

0 · sheet metal box layout

1 · sheet metal box fabrication

2 · sheet metal box drawing

3 · sheet metal box design guide

4 · sheet metal box design

5 · sheet metal blueprints

6 · metal box fabrication

7 · metal box design

The ideal size of hole saw for a round electrical box is 3 inches in diameter. This size allows for a secure fit of standard electrical junction boxes. A properly sized hole ensures that the box is held securely and allows for safe electrical connections.

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my two previous sheet metal Instructables.

A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal .In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my two previous sheet metal Instructables.A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. Fabricating a sheet metal box can seem daunting, but with the right tools and techniques, it can be a straightforward process. In this article, we’ll go over the steps to fabricate a sheet metal box, including cutting, bending, and welding.

Fabricating a sheet metal box can be a rewarding DIY project or a valuable skill for professionals. In this comprehensive guide, we'll walk you through the step-by-step process of creating a sheet metal box, ensuring you have all the information you need to succeed. _____My Favourite Tools (Through Amazon Influencer Shop): https://www.amazon.com/shop/depyrol_____Podcast:https://i.

This is another great beginner sheet metal project I use in my shop classes. I use it to teach print reading skills and order of operations to my students. . Fabricating a sheet metal box involves transforming a flat sheet of metal into a three-dimensional structure with sides and a bottom. This process requires precision, careful planning, and the use of various techniques.

How to Make a Sheet Metal Box: 1) first you want to make an expanded template for your box out of cardboard, paper, etc. ( a flat version of your box. I have a graph paper drawing in the pics below, but its not for this box) 2) trace your template on to your piece of sheet m.

Creating sheet metal boxes involves a series of precise steps that ensure the final product is both functional and aesthetically pleasing. This guide will take you through the process of designing, cutting, and folding sheet metal to create durable and well-fitted boxes.Here is a step-by-step guide to creating custom sheet metal boxes. Measure and cut the sheet metal. First, measure the item that you need to store. Then, using a metal shear, cut the sheet metal to the correct size. Mark the folding lines. Using a ruler and a marker, mark the folding lines on the sheet metal.In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my two previous sheet metal Instructables.

A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. Fabricating a sheet metal box can seem daunting, but with the right tools and techniques, it can be a straightforward process. In this article, we’ll go over the steps to fabricate a sheet metal box, including cutting, bending, and welding.Fabricating a sheet metal box can be a rewarding DIY project or a valuable skill for professionals. In this comprehensive guide, we'll walk you through the step-by-step process of creating a sheet metal box, ensuring you have all the information you need to succeed. _____My Favourite Tools (Through Amazon Influencer Shop): https://www.amazon.com/shop/depyrol_____Podcast:https://i.

This is another great beginner sheet metal project I use in my shop classes. I use it to teach print reading skills and order of operations to my students. . Fabricating a sheet metal box involves transforming a flat sheet of metal into a three-dimensional structure with sides and a bottom. This process requires precision, careful planning, and the use of various techniques.How to Make a Sheet Metal Box: 1) first you want to make an expanded template for your box out of cardboard, paper, etc. ( a flat version of your box. I have a graph paper drawing in the pics below, but its not for this box) 2) trace your template on to your piece of sheet m. Creating sheet metal boxes involves a series of precise steps that ensure the final product is both functional and aesthetically pleasing. This guide will take you through the process of designing, cutting, and folding sheet metal to create durable and well-fitted boxes.

sheet metal box layout

sheet metal looking car

Install a junction box at the water heater end of the cable if there isn't one already. In that junction box, use red or tan wire nuts to splice from the #10 to #12/14 wire(s). Share

best way to make sheet metal box|sheet metal box layout