parts of cnc machines Learn about the 13 key components and elements of CNC machines, such as the input device, the control unit, the drive system, the . Metal building insulation is available in a variety of materials and forms, each with its unique properties and benefits. The most commonly used types of insulation for metal buildings include: Fibreglass insulation is made from tiny glass fibres that are spun and woven together to create a material with excellent thermal insulating properties.

0 · schematic diagram of cnc machine

1 · parts made by cnc machine

2 · main components of cnc machine

3 · cnc machine parts list pdf

4 · cnc machine parts list

5 · cnc machine parts diagram

6 · block diagram of nc machine

7 · block diagram of cnc machine

Rectangle Steel Tube is a welded structural grade tubing that is available in either type A513 or A500 Grade B, depending on its size and wall thickness. Either grade is ideal for all structural applications, general fabrication, manufacturing .

In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF. Learn about the 13 key components and elements of CNC machines, such as the input device, the control unit, the drive system, the . With CNC machines, quality is consistent and not dependent solely on operators. Pro-Tip: Check out our Ultimate Guide to CNC Machining to learn more about CNC machining! 13 Key Components of a CNC Machine. .Apart from these, a bed, spindle, worktable, axis, and control panel are common parts of this CNC machine. CNC Plasma Cutters: CNC plasma cutters are amazing when cutting hard materials into shapes and parts. CNC plasma .

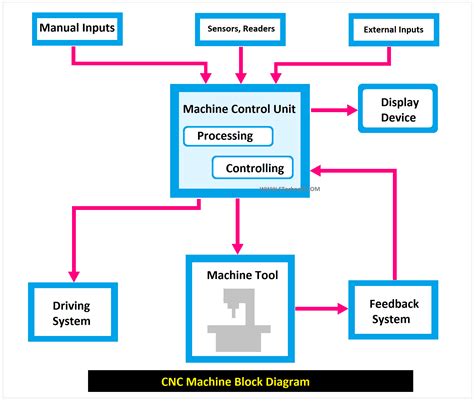

Order CNC Machine Parts From Industrial Automation Co. Industrial Automation Co. is the go-to supplier of crucial CNC machine parts like spindle drives and motors, CNC servo drives, and AC servo motors. We . Main Components (Parts) of CNC Machine. A CNC (Computer Numerical Control) machine is a sophisticated piece of equipment used in manufacturing and machining processes to automate and control the movement of tools and workpieces with a high degree of precision. CNC Machine Block Diagram. CNC machines are modern subtractive manufacturing equipment, which automatically control the tool path and movement for material removal. You can find different types of CNC machines in industrial factories and the CNC Machine Shop, each with specific manufacturing purposes.However, all of them are used to craft the blank work material into the .

The development of CNC machine tools started in the United States. In 1948, Parsons Co. had a preliminary idea to develop a CNC machine tool while working on a project to create a machine tool for processing the inspection template for helicopter blade profiles. The following year, with support from the United States Air Force Logistics Department, Parsons .7 Parts of a CNC Machine +7 CNC Block Diagram. CNC (Computer Numerical Control) machines have revolutionized modern manufacturing by automating precision tasks, reducing human error, and increasing production efficiency. Understanding the key components of a CNC machine is crucial for anyone involved in manufacturing or interested in this .Therefore, CNC laser engraving machines are usually used to produce parts and parts of engraving machines. Laser engraving is widely used in decorative crafts, including signage, wood art, and glass engraving. When narrow tolerances and precise results are required, use CNC laser cutting. . CNC machines are used in 3D printing shops and other .

schematic diagram of cnc machine

17. CONCLUSION • The advantage of a CNC system are that the operation of a conventional machine is removed and the part production is made automatic. • It reduces the labor work and hence highly efficient in the manufacturing process. • BHEL generally uses CNC machines to achieve its manufacturing targets. A CNC milling machine parts Bed. The hardened part of the machine that carries all the load. All the other components are mounted over the bed. It is made of hard metal, and as the tool turret travels over this part. Headstock: It is the main part of the CNC machine. The workpiece is fixed on the headstock to carry out the desired operation. Unlike a lathe machine – on which a workpiece spins and the cutting tool moves into it to create cylindrical shapes – the CNC milling machine employs end mills, dovetail cutters, face mills, and various other milling cutters to machine flat and irregular surfaces, including those that are concave or convex.

CNC machines: CNC machines are computer-controlled machines that can perform various tasks, such as cutting, drilling, engraving, and 3D printing.They use different tools and methods depending on the material and the desired shape. CNC milling machines: CNC milling machines are used to make metal parts with high precision and accuracy.They have a . 2. Fictiv Blog: “Parts of a CNC Machine Explained” Summary: This blog post from Fictiv delves into the various parts of a CNC machine, including their specific roles and how they contribute to the machine’s functionality. The article is structured to provide both a high-level overview and in-depth information about each component, making .

china stainless steel 304 lunch box suppliers

What are the Parts of a CNC Machine? Bed: Typically constructed from cast iron for enhanced durability and strength, the bed is the machine’s foundation, supporting all components.. Spindle: Inside the machining area, the electrically driven spindle rotates tools that cut and shape the parts. The inside of the spindle is tapered to match the tapered angle of the tool holder to . How Do CNC Machines Work? First, let’s understand how a CNC machine works.CNC machines rely on precise coordination and automation to manufacture parts efficiently. Different parts of the CNC machine, such as .Take the time to familiarize yourself with the different parts of a CNC machine, such as the frame, motors, spindles, linear guides, and control system. Understanding the function and relationship between each part will make the assembly process much easier. 3. Assembling the Frame .From a small door lock part to the large scale of aerospace parts production, the CNC machining process can meet the requirements with the programming language, CNC machines, tools and the understanding of CNC machining .

Upgrading CNC machine parts is a viable option for enhancing performance and extending the machine’s lifespan. However, whether to upgrade or replace parts depends on several factors. Necessity of Upgrades: Upgrades are often necessary to keep up with technological advancements and improve machining accuracy and speed. For example, . Step 3: Machining: The CNC machine reads the G-code and performs precise operations, such as cutting or drilling, on the raw material. Step 4: Finishing: The machine finishes the part with smooth cuts and accurate dimensions. Types of CNC Machines. CNC Milling Machine: Used for cutting, shaping, and drilling materials.Advantages of CNC milling machines. CNC milling machines advantages are, CNC machines can work continuously. They can be used 24 hours a day only needed to switch off in case of maintenance. The program loaded in the CNC machines can be loaded thousands of times producing the exact same products. The software can be updated for up-to-date features.

3. Introduction to CNC 3 Numerical control (NC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium, as opposed to controlled manually. Most NC today is computer numerical control (CNC), in which computers play an integral part of the control. In modern CNC systems, end-to-end component .

CNC machines can have parts with intricate designs and tight tolerances essential in medical applications. 4. Electronics Industry: CNC machining is an indispensable technology in the electronics . 2. v CNC MACHINES o Modern manufacturing systems are advanced automation systems. The numerical control (NC) and computer numerical control (CNC) machines are an integral part of the automation systems. o CNC machining is capable of meeting the tightest tolerances, and producing the most accurate, precise products over and over again. CNC Machine के महत्वपूर्ण अंग -: हम जानते हैं कि प्रत्येक मशीन छोटे - छोटे पार्ट या भाग से मिलकर बनता है। ठीक इसी प्रकार CNC Machine का निर्माण भी कई भागों को आपस मे . To delve deeper into the synergy of the CNC lathe machine parts, consider the following illustrative analogy, albeit not a perfect comparison: Headstock: It’s like the motor of a kitchen blender. It powers and controls the main spinning part. CNC Lathe Bed: Imagine a long, sturdy kitchen counter. Everything is placed on it, and it supports .

The best upgrade for CNC lathe machine parts varies depending on user needs. A range of possible improvements can be considered depending on the quality of the lathe machine parts. Examples are: Improved Controller: Better controller hardware can improve capabilities and program editing. Non-specialist hardware from sources like Amazon and . Used in manufacturing, signage, and decorative parts. CNC drilling machines: These machines are designed to create holes in workpieces, offering a much more efficient alternative to manual drilling methods. They are useful in any application that requires precise holes, such as manufacturing electronic components or mechanical parts. .

parts made by cnc machine

china stainless steel lunch box set factories

china stainless steel cnc turning manufacturers

Synthetic underlayment is a newer innovation that is taking over the metal roofing industry as a better, more advanced replacement for felt underlayment. Most synthetic underlayments are mechanically attached with roofing caps .

parts of cnc machines|schematic diagram of cnc machine