can you put 240v in a junction box For instance, the best way to conceal such a junction box is to use a large, deep 4-11/16" square metal box (which you need for the cubic inches), then stick a 2-gang "mud ring" on it, then stick plain 120V receptacles or switches there, fed by totally separate 120V / #12 wires. The most common electrical box screw size is 6-32 machine screw. However, for many applications, 6-32 is too light duty, so we use an 8-32 or even a 10-32 instead. The thread pitch, however, is always 32.

0 · waterproof electrical connectors 240v

1 · electrical box for 240v range

2 · b&q electrical junction box

3 · 240v junction box wiring

4 · 240 volt junction box

5 · 240 volt electrical junction box

6 · 240 volt breaker box

7 · 240 amp breaker box

The most common plumbing pipes you’ll find inside a home are PVC, PEX, ABS, copper, or galvanized steel pipe. How often does plumbing need to be replaced? The frequency at which you need to replace pipes is based on the pipe material used.

For instance, the best way to conceal such a junction box is to use a large, deep 4-11/16" square metal box (which you need for the cubic inches), then stick a 2-gang "mud ring" on it, then stick plain 120V receptacles or switches there, fed by totally separate 120V / #12 wires.You can only have one receptacle on a 30A 240V circuit. It sounds to me like you .The box needs to be of an adequate size and type, the box must be readily . You can only have one receptacle on a 30A 240V circuit. It sounds to me like you should pull a new home-run circuit to the new dryer location and install a new breaker for it, or .

waterproof electrical connectors 240v

electrical box for 240v range

The box needs to be of an adequate size and type, the box must be readily accessible, the type of splice must be correct and of the correct sized wire and type, etc etc. .You can tell the two types apart by the slanted vs parallel prongs. And yes, having that ground wire gives you the freedom to code-legally extend the circuit. The existing electrical box behind .Junction box is fine. It's fine. Just make sure the junction box remains accessible and the wire is protected from damage. It would need to be a listed junction box and the wiring would need to .

If you mean a 240 supply source from a distribution panel to a junction box then the answer is yes. You have to keep in mind that the box has to be accessible, meaning that .

I'm getting my electric tanked water heater replaced in the next few weeks, and it's fed by a 240v 30A circuit, with a junction box just above where the heater will be. I've been looking into . You can use a junction box to extend wiring. In fact, it’s the preferred method. The alternative—splicing—has its limitations and is usually unsafe and not up to code. Outside location in a weather proof box. Is it legal to use the same outside box for 1 receptical with 120 and the other 240? No pigtails, I ran 2 separate circuits from the panel to .

types of lights with junction box inside the light

b&q electrical junction box

types of sheet metal joints and their uses

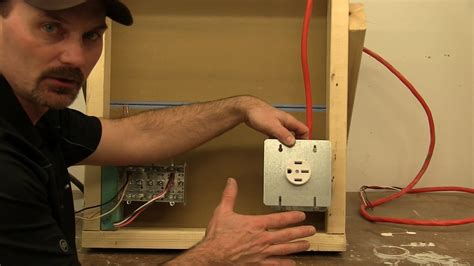

These include an appropriately sized junction box, electrical cable suitable for 240 volts (commonly known as 10-3 or 8-3 cable), an outlet receptacle rated for 240 volts, and wire . For instance, the best way to conceal such a junction box is to use a large, deep 4-11/16" square metal box (which you need for the cubic inches), then stick a 2-gang "mud ring" on it, then stick plain 120V receptacles or switches there, fed by totally separate 120V / #12 wires. You can only have one receptacle on a 30A 240V circuit. It sounds to me like you should pull a new home-run circuit to the new dryer location and install a new breaker for it, or not re-purpose the old receptacle/circuit. The box needs to be of an adequate size and type, the box must be readily accessible, the type of splice must be correct and of the correct sized wire and type, etc etc. But there is nothing in particular that is wrong with having a junction box for a 30A 240V circuit.

You can tell the two types apart by the slanted vs parallel prongs. And yes, having that ground wire gives you the freedom to code-legally extend the circuit. The existing electrical box behind the outlet would become the junction box, and you'd just put a .

Junction box is fine. It's fine. Just make sure the junction box remains accessible and the wire is protected from damage. It would need to be a listed junction box and the wiring would need to be installed according to the NEC. If you mean a 240 supply source from a distribution panel to a junction box then the answer is yes. You have to keep in mind that the box has to be accessible, meaning that you can get to the. I'm getting my electric tanked water heater replaced in the next few weeks, and it's fed by a 240v 30A circuit, with a junction box just above where the heater will be. I've been looking into powered anode rods, but there's no outlet box nearby.

You can use a junction box to extend wiring. In fact, it’s the preferred method. The alternative—splicing—has its limitations and is usually unsafe and not up to code. Outside location in a weather proof box. Is it legal to use the same outside box for 1 receptical with 120 and the other 240? No pigtails, I ran 2 separate circuits from the panel to each outlet via underground conduit. These include an appropriately sized junction box, electrical cable suitable for 240 volts (commonly known as 10-3 or 8-3 cable), an outlet receptacle rated for 240 volts, and wire nuts to securely connect the wires.

240v junction box wiring

For instance, the best way to conceal such a junction box is to use a large, deep 4-11/16" square metal box (which you need for the cubic inches), then stick a 2-gang "mud ring" on it, then stick plain 120V receptacles or switches there, fed by totally separate 120V / #12 wires.

You can only have one receptacle on a 30A 240V circuit. It sounds to me like you should pull a new home-run circuit to the new dryer location and install a new breaker for it, or not re-purpose the old receptacle/circuit.

The box needs to be of an adequate size and type, the box must be readily accessible, the type of splice must be correct and of the correct sized wire and type, etc etc. But there is nothing in particular that is wrong with having a junction box for a 30A 240V circuit.

You can tell the two types apart by the slanted vs parallel prongs. And yes, having that ground wire gives you the freedom to code-legally extend the circuit. The existing electrical box behind the outlet would become the junction box, and you'd just put a . Junction box is fine. It's fine. Just make sure the junction box remains accessible and the wire is protected from damage. It would need to be a listed junction box and the wiring would need to be installed according to the NEC. If you mean a 240 supply source from a distribution panel to a junction box then the answer is yes. You have to keep in mind that the box has to be accessible, meaning that you can get to the.

I'm getting my electric tanked water heater replaced in the next few weeks, and it's fed by a 240v 30A circuit, with a junction box just above where the heater will be. I've been looking into powered anode rods, but there's no outlet box nearby. You can use a junction box to extend wiring. In fact, it’s the preferred method. The alternative—splicing—has its limitations and is usually unsafe and not up to code.

Outside location in a weather proof box. Is it legal to use the same outside box for 1 receptical with 120 and the other 240? No pigtails, I ran 2 separate circuits from the panel to each outlet via underground conduit.

types of sheet metal brackets

Without some kind of guide, it can be difficult to install the boxes with the .

can you put 240v in a junction box|240 volt electrical junction box