k factor chart sheet metal The neutral layer, though invisible within the sheet metal, plays a pivotal role in bending operations and is intrinsically linked to the . See more Custom Sheet Metal Fabrication in Wichita. Trust our comprehensive fabrication services to bring your ideas to life with expert fabrication solutions in Wichita, KS.

0 · stainless steel k factor chart

1 · solidworks sheet metal k factor

2 · sheet metal k factor table

3 · how to calculate k factor

4 · calculate k factor sheet metal

5 · bending calculation for sheet metal

6 · bending allowance in sheet metal

7 · bend allowance k factor chart

However, some electricians install electrical outlets upside down as a standard practice to indicate that the outlet is controlled by a wall switch. This can be a helpful visual cue for homeowners, making it easier to identify switched outlets.

The K-factor is a crucial concept in sheet metal design and fabrication, particularly when working with CAD software like SolidWorks. It represents the location of the neutral axis within a bend and plays a vital role in determining the accurate length of sheet metal parts after bending. Mathematically, the K-factor is . See moreTo fully grasp the K-factor, it’s essential to understand the concept of the neutral layer. When a sheet metal part is bent, the material near the inner surface of the bend undergoes . See moreThe illustrations below provide a detailed visual explanation of the K-factor concept: In the cross-section of a sheet metal part, there exists a neutral . See moreThe neutral layer, though invisible within the sheet metal, plays a pivotal role in bending operations and is intrinsically linked to the . See more

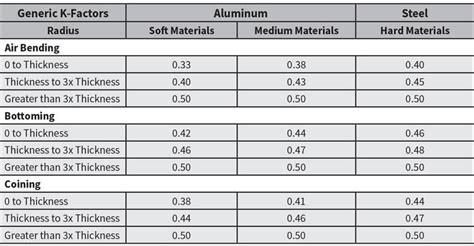

Therefore, the bending allowance (BA) should be equal to the length of the neutral layer arc in the bending area of the sheet metal part. This arc . See moreA K-Factor will typically range between 0 and .5 for standard materials and thicknesses though smaller and larger K-Factors are possible. To help you begin I’ve included a K-Factor Chart below which contains common K-Factor starting . The k-factor is fundamental to designing precise sheet metal products. It allows you to anticipate the bend deduction for a large variety of angles without having to rely on a .

The K-factor in Welding. In sheet metal, the K-factor is the ratio of the neutral axis to the material thickness. When a piece of metal is being formed, the inner portion of the bend . The SkyCiv K-Factor for Sheet Metal is a free tool designed to help engineers and fabricators understand the effects of their sheet metal bending designs. Knowing the k-factor formula is essential in order to bend any kind of sheet metal correctly; in fact, it varies according to the type of material to be deformed. What is the k-factor? The k-factor indicates the behaviour of the .

stainless steel k factor chart

The correct K-factor to use in your CAD program can now be calculated as follows: BendDeduction = Length X + Length Y - Total Flat Length OutSideSetBback = .Use our K-factor calculator to determine the position of the neutral axis in the sheet of metal you are planning to bend.The sheet metal k factor is a crucial parameter used during the bending and folding process of metal sheets. The degree of deformation of the metal sheet upon bending is indicated and usually represented as a decimal value. The K .

What is the K Factor in Sheet Metal? K-Factor is the ratio of the distance (t) of the neutral axis from the inside bend and the sheet thickness (T) when you bend the sheet metal piece. This has been illustrated in the image . Many designers reference a chart like this or use test pieces to calculate the K-Factor for specific projects. SOLIDWORKS defaults to calculating the flat pattern using the K-Factor. This is a decently conservative approach .

metal boxes shall be _____ in accordance with article 250.

I’d like to review K-Factor and how K-Factor applies to your sheet metal designs. K-Factor Defined. K-Factor– A constant determined by dividing the thickness of the sheet by the location of the neutral axis, which is the part of .What is K-factor? K-factor is a crucial parameter used in sheet metal bending calculations. It represents the location of the neutral axis in a bent sheet metal part. The neutral axis is the theoretical line within the material thickness where neither . Use one of the listed K-Factor calculators and measurement of a sample bent part: K Factors Autodesk Inventor; Inventor K Factor Calculator; Manually calculate the K-Factor using the measure of sample sheet metal parts that were bent using the following formula: The k-factor is fundamental in the press-bending sector and is closely linked to the concept of spring back. It is also known as bend allowance and serves to calculate the sheet metal layout. Knowing the k-factor formula is essential in order to bend any kind of sheet metal correctly; in fact, it varies according to the type of material to be deformed. .

Bend relief notch 4. A consistent bend orientation is important for ease of fabrication.. 5. The K-factor of your bending design should be chosen from a K-factor chart based on the material type, bend angle, and operation. It typically ranges from 0.25 to 0.50. 6. If your design has offset bends ( Z-shaped), Maintain flange length (on Both Sides)= 3 x thickness(t) The K-factor is determined by the physical properties of the material, bending method, bending angle, and other factors. Material Properties: it typically ranges between 0.30 and 0.50.In general, the K-factor of soft copper or soft copper materials is 0.35, the K-factor of materials such as semi-hard copper or brass, mild steel and aluminium is 0.41, and the K .CATIA V5 is the metal bending software of choice across many industries. This tutorial covers how the K-Factor impacts metal bending and Learn how to calculate the K-factor in Sheet Metal Bending with this CATIA V5 tutorial.

K-factor – Effectively 50%T Max / .25%T Min Where the neutral axis is situated in a bend is commonly called the “K-Factor” as it is signified as “K” in the development formulas. Since the inside compression can not exceed the outside tension, the k-factor can never exceed .50 in practical use. This

The K-factor in sheet metal is a ratio to determine where the neutral axis (where the material is neither in compression nor tension) lies within the thickness of the bent material. It is important to predict the bending allowance, which is the amount of material needed to achieve a desired bend. This is important for designers and fabricators . To arrive at 0.0078, the equation uses a k-factor of 0.4468, a commonly used factor that’s the default for many CAD systems. To dial in your bend calculations, you first need to determine whether you go with the default k-factor value of 0.4468, calculate a custom k-factor, or reverse-engineer it based on some test bends. The K factor is a key metric in many fields like statistics, engineering, and manufacturing. This article will explore what the K factor is, how it’s calculated, and its uses. It’s important for data analysts, electrical engineers, and sheet metal workers to know about the K factor. It helps them make better decisions and improve their work.Sheet Metal K-Factor Chart. A K-Factor Chart provides reference values, usually between 0 and 0.5, for common materials like steel, aluminum, and stainless steel. It’s a starting point for general fabrication, indicating typical deformation degrees for various thicknesses and materials.

If the value of sheet metal K factor and bending flange length is known. Sheet Metal flat length can be calculated in the following three steps. Step-1: Calculate the value bend allowance for the required sheet metal bend by using the below formula. Bend Allowance (BA) = (Π/180) × . The k-factor describes the neutral axis’s inward shift during bending. Press brake operators can calculate it precisely, especially after some test bends, but know that the k-factor is just one among many. . When sheet .

The biggest difference between the k-factor and the y-factor in sheet metal bending is that the y-factor takes the internal stresses of the material into account more so than the k-factor does. This means that calculations .K-Factor is a ratio that represents the location of the neutral sheet with respect to the thickness of the sheet metal part. When you select K-Factor as the bend allowance, you can specify a K-Factor bend table. The SOLIDWORKS application also comes with a K-Factor bend table in Microsoft Excel format.

Ever wonder what "K-Factor" means when defining your Sheet Metal Rules in Fusion 360? This Quick Tip provides more insight on how the K-Factor is used to det.

A well-maintained bend allowance chart is a vital tool in the sheet metal fabrication industry. It ensures precision and efficiency in the bending process, ultimately leading to higher quality and more accurate finished products. . Unlock the secrets of the K-factor, a crucial concept in sheet metal fabrication. In this article, our expert .

In order to simplify the definition of the sheet metal neutral layer and make it applicable to all materials, the concept of the K-factor was introduced. The definition of the K-factor is: it is the ratio of the thickness of the sheet metal’s neutral layer to the overall thickness of the sheet metal part material.I haven't made any super complicated sheet metal parts but usually there is a way to model the features in as solids / sheet metal features and achieve the correct results. Reply . You can also make a k-factor chart to help for future reference. We have one buts we made it all for od bends and dimensionsK Factors + Bending Info - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document provides information on bend factors ('K-factors') for various materials and bend types in sheet metal bending. It includes a table of K-factors for mild steel and stainless steel in normal and hem bends with various material thicknesses and bend radii.

solidworks sheet metal k factor

Y factor and K factor represent part constants used in formulas to calculate the developed length of flat sheet metal required to make a bend of a specific radius and angle in a design. Y factor and K factor are defined by the location of the sheet metal .

Instructions for Optimal Use: Input Material Thickness and Inner Radius: • Enter the precise sheet thickness and desired inner bend radius. • The calculator will instantly provide the K-factor, Y-factor, and neutral layer position, crucial for accurate bending calculations.How to calculate bend allowance, K factor and Y coefficient in one click. To calculate the bend allowance, the K factor and the derived coefficient called the Y factor, insert the thickness and initial length of the sheet into the cells on the left.After bending the sheet, insert the inner radius, and flanges A and B. Bending angle is 90°.To change the K-Factor for a sheet metal part, select the root node in the Mechanical Browser and type a value in the K-Factor field. The value must lie in the range [0, 1], since the neutral surface is located inside the sheet metal part. In BricsCAD the K-Factor is defined for bend radius equal to the material thickness (R/T = 1). You can easily modify the Material Thickness, Inside Radius, and K-Factor for each thickness at the top of each column. This chart is for reference only – you should always verify your process for better results. Sheet Metal Bend Deduction Chart (PDF) Sheet Metal Bend Deduction Chart (Excel) CONCLUSION

metal boxes warhammer

metal bracket fabrication near me

If a door is placed between a residential dwelling and the garage, it must be covered by the International Residential Code (IRC). This includes: A solid wood door at least 1 3/8 inches thick; A solid steel door at least 1 3/8 .

k factor chart sheet metal|calculate k factor sheet metal