ways to fabricate metallic implants This review article focuses on classifying metallic implants by material types and how the materials science aspects of bulk and surface of metallic biomaterials are modified to enhance biocompatibility, i.e., biological responses such as early-stage osseointegration as . Buy iron window boxes direct from UK manufacturer. Bespoke window box designs available. High quality range in zinc galvanized steel.

0 · Revolutionising orthopaedic implants—a comprehensive review

1 · Recent advances of additive manufacturing in implant fabrication

2 · Recent Advancements in Materials and Coatings for Biomedical

3 · Metallic Implants for Biomedical Applications

4 · Improving biocompatibility for next generation of metallic implants

5 · Additively manufactured metallic biomaterials

6 · Additive manufacturing technology for porous metal implant

7 · Additive Manufacturing of Customized Metallic

8 · A comprehensive review on metallic implant biomaterials and

9 · A comprehensive review on metallic implant biomaterials

10 · 3D Printing Technologies in Metallic Implants: A Thematic

Zinus Walter Standard Profile Metal Smart Box Spring / Mattress Foundation / Wood Slat Support / Easy Assembly

This review article focuses on classifying metallic implants by material types and how the materials science aspects of bulk and surface of metallic biomaterials are modified to enhance biocompatibility, i.e., biological responses such as early-stage osseointegration as .

lunch boxes steel

The only example is the endodontic stabilizer. 3. Implants used in .As a first part of a biocompatibility testing programme, in vitro corrosion tests were .A review of the method of self-propagating high-temperature synthesis (SHS) is .

Revolutionising orthopaedic implants—a comprehensive review

The porous magnesium specimens were immersed in physiological saline .Among various methods, surface modification on metallic surfaces by applying coatings is an effective way to improve implant material performance. In this review, we discuss the recent .

Additive manufacturing through powder bed fusion shows great potential for the fabrication of high-quality porous metal implants. However, the powder bed fusion technique .Following are some commonly employed non-traditional machining techniques to modify the metallic implant biomaterials’ surfaces for implant applications. 7.2.1 AWJM technique .Mohammad Alkhreisat, Ashfaq Mohammad & Islam Shyha. 1603 Accesses. Explore all metrics. Abstract. This paper conceptualises an understanding of advanced manufacturing methods to . Applying additive manufacturing (AM) techniques can transform different areas of biomedical implants, such as tailored prosthetics, individualized implants, functional implants .

Recent advances of additive manufacturing in implant fabrication

Recent Advancements in Materials and Coatings for Biomedical

The most widely used metal additive manufacturing processes for fabrication of metal implants. (A) Laser powder bed fusion (LPBF), (B) electron beam powder bed fusion .

Until now, lots of methods have emerged and used in this field with diverse characteristics. This review aims to comprehensively discuss 3D printing (3DP) technologies .

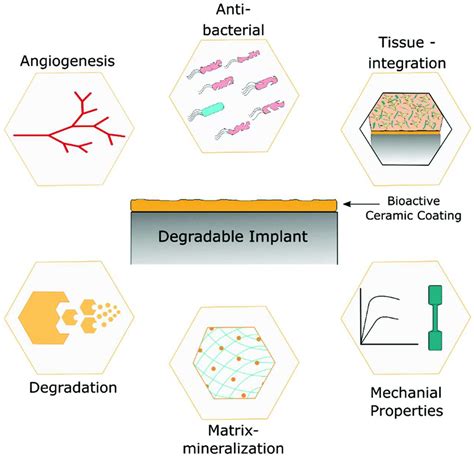

Through alloying and processing, metallic implants can be made to resist corrosion when they are used to permanently replace tissue, or degrade in a controlled manner for applications where tissue regeneration is expected.

To meet the performance requirements of implants, this paper introduces the biomedical metallic materials currently applied to orthopedic implants from the design to manufacture, elaborates the structure design and surface . The Problems with Metal Implants . Both conventional and holistic dentists typically recommend implants as the next step after extraction for most people. Most conventional dentists will suggest titanium metal implants . 250 Lombard Street, 1st Floor Thousand Oaks, CA 91360. 805.495.3687release of metal ions from the implants and this leaching has been attributed to corrosion process. It has been well accepted that the tolerable corrosion rate for metallic implant systems should be about 2.5 x 10-4 mm/yr, or 0.01 mils/yr [19]. The most common forms of corrosion that occur are uniform corrosion, intergranular,

For instance, titanium implants are metallic grey in color and have a smooth or rough texture depending on the treatment process used in their manufacturing. Zirconia, on the other hand, is white or tooth-colored and typically has a smoother texture. . Technological advancements are revolutionizing the way we approach dental health, leading .Gold and silver can be reused for jewelry, electronics, and new dental implants; platinum and palladium will be recycled for catalytic converters, electronic equipment, medical and dental implants. Lower grade metals can be sold as scrap. Benefits. Without a doubt, metal implant recycling benefits all those involved in the process.

bone implants for surgeries in orthopedics, dentistry, neurosurgeries, and cranioplasties in both oral and maxillofacial surgery [3 5]. Direct metal laser sintering (DMLS) is the most widely used metal 3D printing tech-nology. DMLS and SLM (selective laser melting) are used by technicians interchangeably, but they are also slightly different. This is a permanent restoration. However, the overdenture can be removed for cleaning and dental exams.. The average cost ranges from ,000 to ,000 per arch. 4. 3-on-6 Dental Implants. An alternative to an implant-retained denture is a 3-on-6 implant.It consists of three individual dental bridges attached to six dental implants.

Powder bed fusion additive manufacturing (AM) technologies, including electron beam melting (EBM) methods, can be selected to fabricate metal frameworks in prosthodontics. 1, 2 Powder bed fusion . The 3D printed implants have attracted much attention in recent years since they are amenable to rapid production, custom-built design, and precise control over the dimension and porosity. In this regard, the present review focuses on the history of various AM methods that are utilized in the production of metallic implants.Pure metal implants do not integrate with bone and, like all bio-inert materials, are surrounded by dense fibrous tissue that prevents the desired stress distribution, with the possible result of implant loosening. . In this way, a high-strength frame is created on which a special dental porcelain (i.e., an aesthetic coating) is deposited and .

The benefits and limitations of titanium metal printing for dental implant prototypes are presented by the authors. Discover the world's research 25+ million members

Metallic Implants for Biomedical Applications

Advanced metal implants are used in modern medical practice and significantly improve clinical progn . scientific publications on the impact of heavy metal compounds released from medical implants on patients’ health and ways to modify implants that can prevent this process. M ETHODS Ethical consideration. A study was approved by the Ethics . However, a high number of implants is placed yearly, and in fact, more than 3 million implants are placed in the USA alone, with a worldwide market growing up to 500,000 implants each year . Notably, other types of medical devices face the same problems, and for instance, biofilm formation on contact lenses may result in various severe ocular . Furthermore, when compared to alternative tooth replacement options, dental implants appear by far the most natural. 8 Ways To Afford Dental Implants Cost. Have you put off obtaining dental implants due to the exorbitant cost? True, the dental implants cost can be intimidating, but it is worthwhile, and here are some methods to make it more . The decrease in atmospheric pressure during rainfall can directly impact metal implants in two significant ways: expansion and contraction. As air pressure decreases around an implant site due to rain showers, the surrounding tissues undergo expansion while attempting to reach equilibrium with lower external pressures.

Pat's is not an isolated case. In fact, any metal implant or device — be it a spinal cord stimulator, as Pat had, dental implant to take the place of lost teeth, or hip and knee replacement — can potentially lead to a hypersensitivity .

Table 2 shows ISO and ASTM requirements for HA coatings. Different techniques such as electrophoretic deposition, ion-beam sputter coating, dip coating, plasma spraying, etc. are used to coat metallic implants with HA . Conclusion: Additive manufacturing technology may provide an efficient alternative way to fabricate customized dental implants based on a CAD file with a functionally graded structure that may . Metal Artifacts. Metal streak artifacts are quite common in CBCT scans, often caused by patient-related objects such as implants, crowns, posts, fillings, and other radiopaque materials. These high-attenuation objects cause noise scattering and beam hardening, often resulting in bright and dark streaks that degrade the image quality.

As a metal additive manufacturing technology, laser powder bed fusion (L-PBF) has the advantages of design freedom and formation precision by using fine powder particles to reliably fabricate metallic implants with customized structures according to patient-specific needs. In the case of porous metallic orthopedic implants and scaffolds, AM-based processes lead the recent advances. Various AM processes are currently being used to manufacture metallic implants, figure 1 [13, 86]. The AM technologies have significantly contributed to porous scaffolds to enhance biocompatibility [87–89].In recent years, metal-free dental implants have gained popularity as a modern and innovative alternative to traditional metal implants. These implants, made from biocompatible materials, offer several advantages and unique characteristics that make them a preferred choice for many individuals seeking tooth replacement solutions. For metallic biomaterials, the critical benchmarks include outstanding biocompatibility and mechanical properties, controlled corrosion profile (high chemical inertness and corrosion resistance for permanent implants, and a controlled degradation profile for resorbable platforms), appropriately high resistance to wear (especially for articulating parts), .

With demand for joint replacements exploding as populations age, materials used by medical implant and medical device manufacturers continue to evolve. Metallurgists and materials scientists are seeking more-innovative ways to improve the quality and longevity of surgical implants. Metals such as titanium, cobalt chromium, and other alloys are the materials . Commercially available porous metallic orthopedic devices. A. Arcam designed hip cup using electron beam melting (EBM) technology (courtsey GE additive) [44], B. Lattice-structured implant . This review aims to introduce the AM technologies in implant applications and find new ways to design more sophisticated methods and compatible implants that mimic the desired tissue functions .

The implant and metal substructure were intact and surrounding periodontium was healthy. How do you remove the crown from the abutment without damaging the abutment or the implant? . The implant systems are engineered this way with the screw being the weakest link to fracture instead if the implant. It is just the way it is. Often when an .

Improving biocompatibility for next generation of metallic implants

Remove the two 10 mm bolts and pull the front piece off the ebox. Move the two wiring harnesses around. Squeeze them, twist them, etc, and see if that allows your display to come on. If so, you have a bad connection there and its an easy fix.

ways to fabricate metallic implants|Recent Advancements in Materials and Coatings for Biomedical