does a junction box need a rear clamp They have rear and side knockouts that require supplementary clamps, and these knockouts can be hard to remove. In addition, their sharp edges can injure hands. It's usually . In this blog post, we will explore the key factors that affect MIG welding sheet metal, including wire size, gas selection, amperage, and voltage. We will also provide tips and best practices to help you achieve optimal .

0 · wiring junction box installation

1 · how to install electrical junction box

2 · electrical junction boxes

3 · electrical junction box replacement

4 · electrical junction box problems

5 · electrical junction box extension

6 · electrical junction box cover

7 · back of box cable clamp

With houses and other small, residential buildings, the phone company supplies wires from their pole or underground lines, and terminates them in a small junction box or demarc (as in demarcation, and pronounced "DEE-mark" by the guys whose pants hang too low) or network interface device or NID (pronounced "nid" by the aforementioned low-hanging.

There are two functions of a cable clamp - one is strain relief - if the cable is pulled on, the clamp takes that strain, and the electrical connections of the conductors do not. The other is preventing damage to the insulation from contact with the sharp edges of the hole in the box. Per Code, a single-gang plastic box for NM cable need not have a cable clamp. If you're working with the blue Carlon boxes, the most common brand in my area, the single .

They have rear and side knockouts that require supplementary clamps, and these knockouts can be hard to remove. In addition, their sharp edges can injure hands. It's usually . Install a cable clamp for each cable, as needed. Standard plastic electrical boxes do not have knockouts and contain internal cable clamps. Metal boxes usually have internal . Exterior boxes should be attached with screws; the back of the box should have small holes for that purpose. If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on .If the wires are 12-2, you will require 18 cubic inches to splice three wires with ground wire, clamps, and no attached devices per section 314.16. For 14-2 and the same situation, the requirement is 16 cubic inches. Please ensure you .

wiring junction box installation

Two cables will enter the junction box, one will be interior NM 10-3 in ½ inch conduit, and the other a buried-rated NM 10-3 (it’s flat, not round) in 1 inch conduit.

lynden sheet metal lynden wa

It is a fast and easy way to pull NM-cables into a box, but not code approved. The photo below shows NM-cables entering the top of a box through NM-connectors (except that one is . Junction boxes protect electrical wires from damage, prevent shocks, and stop sparks from igniting flammable material nearby. To install one, you’ll need to strip the ends off all the wires that will be in the box. To .

Junction boxes must be made of non-combustible material, such as metal or plastic. They must be suitable for the specific environment in which they are installed. For example, if you need to install your junction box in a damp or . There are two functions of a cable clamp - one is strain relief - if the cable is pulled on, the clamp takes that strain, and the electrical connections of the conductors do not. The other is preventing damage to the insulation from contact with the sharp edges of the hole in the box. Per Code, a single-gang plastic box for NM cable need not have a cable clamp. If you're working with the blue Carlon boxes, the most common brand in my area, the single-gang boxes have four knockouts, one in each corner.

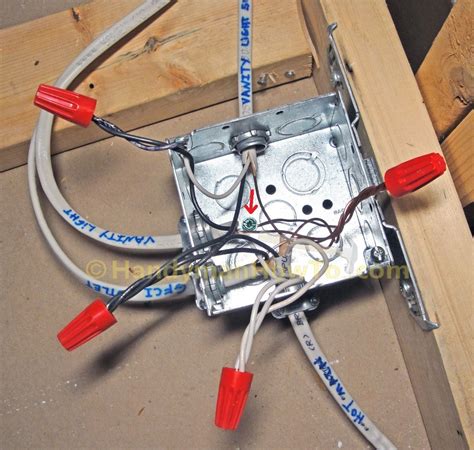

They have rear and side knockouts that require supplementary clamps, and these knockouts can be hard to remove. In addition, their sharp edges can injure hands. It's usually best to wear gloves when working with metal boxes. Install a cable clamp for each cable, as needed. Standard plastic electrical boxes do not have knockouts and contain internal cable clamps. Metal boxes usually have internal clamps; if yours does not, install a locknut-type clamp for each cable. Exterior boxes should be attached with screws; the back of the box should have small holes for that purpose. If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on either side of the box). You’ll also need to install cable clamps in the metal box. These thread into the box from the outside.If the wires are 12-2, you will require 18 cubic inches to splice three wires with ground wire, clamps, and no attached devices per section 314.16. For 14-2 and the same situation, the requirement is 16 cubic inches. Please ensure you have sufficient volume in .

Two cables will enter the junction box, one will be interior NM 10-3 in ½ inch conduit, and the other a buried-rated NM 10-3 (it’s flat, not round) in 1 inch conduit.It is a fast and easy way to pull NM-cables into a box, but not code approved. The photo below shows NM-cables entering the top of a box through NM-connectors (except that one is missing, with a cable poking through it, and will need repair). Junction boxes protect electrical wires from damage, prevent shocks, and stop sparks from igniting flammable material nearby. To install one, you’ll need to strip the ends off all the wires that will be in the box. To complete the electrical circuit, tie together the same-colored wires and hold them in place with wire nuts.

Junction boxes must be made of non-combustible material, such as metal or plastic. They must be suitable for the specific environment in which they are installed. For example, if you need to install your junction box in a damp or wet location, it must . There are two functions of a cable clamp - one is strain relief - if the cable is pulled on, the clamp takes that strain, and the electrical connections of the conductors do not. The other is preventing damage to the insulation from contact with the sharp edges of the hole in the box.

Per Code, a single-gang plastic box for NM cable need not have a cable clamp. If you're working with the blue Carlon boxes, the most common brand in my area, the single-gang boxes have four knockouts, one in each corner. They have rear and side knockouts that require supplementary clamps, and these knockouts can be hard to remove. In addition, their sharp edges can injure hands. It's usually best to wear gloves when working with metal boxes. Install a cable clamp for each cable, as needed. Standard plastic electrical boxes do not have knockouts and contain internal cable clamps. Metal boxes usually have internal clamps; if yours does not, install a locknut-type clamp for each cable. Exterior boxes should be attached with screws; the back of the box should have small holes for that purpose. If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on either side of the box). You’ll also need to install cable clamps in the metal box. These thread into the box from the outside.

If the wires are 12-2, you will require 18 cubic inches to splice three wires with ground wire, clamps, and no attached devices per section 314.16. For 14-2 and the same situation, the requirement is 16 cubic inches. Please ensure you have sufficient volume in . Two cables will enter the junction box, one will be interior NM 10-3 in ½ inch conduit, and the other a buried-rated NM 10-3 (it’s flat, not round) in 1 inch conduit.

It is a fast and easy way to pull NM-cables into a box, but not code approved. The photo below shows NM-cables entering the top of a box through NM-connectors (except that one is missing, with a cable poking through it, and will need repair). Junction boxes protect electrical wires from damage, prevent shocks, and stop sparks from igniting flammable material nearby. To install one, you’ll need to strip the ends off all the wires that will be in the box. To complete the electrical circuit, tie together the same-colored wires and hold them in place with wire nuts.

Center the fan in the room for the best air circulation. Ensure there are at least 18 inches between the blades and any walls. For sloped ceilings, use a special mounting kit designed for angled installation. Always follow safety .

does a junction box need a rear clamp|electrical junction box problems