cnc machine g code list pdf This document shows what are the G codes & M codes required for SINUMERIK programming in Turning and Milling applications. Whether it’s a basic part or a complex workpiece, the . Find models with galvanized 12- and 18-gauge steel that resists corrosion. From metal corner brackets to mending braces, you’ll find everything you need for your next project at Lowe’s. These Angles, Brackets & Braces are the most popular among Lowe’s entire selection.

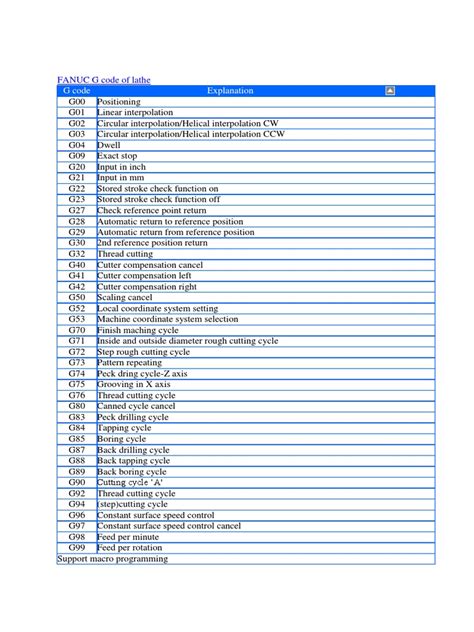

0 · list of fanuc g codes

1 · list of all g codes

2 · g code table listing

3 · g code reference chart

4 · g code for cnc milling

5 · complete g code list

6 · cnc turning g code list

7 · cnc milling g codes list

Now you know the truth: metal roofs are good for keeping your home cooler, as they reflect the sun's rays. Whether your roof is built with asphalt shingles, natural stone, or metal panels, dark .

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.This document shows what are the G codes & M codes required for SINUMERIK programming in Turning and Milling applications. Whether it’s a basic part or a complex workpiece, the .G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

This document shows what are the G codes & M codes required for SINUMERIK programming in Turning and Milling applications. Whether it’s a basic part or a complex workpiece, the Siemens control system offers you a wealth of functionality with a very high degree of operator friendliness and manufacturing eficiency.

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from mach ine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.GPocket Guide and Reference Charts for CNC Machinists – Made in the U.S.A. –

G codes from group B are of "one shot" type (active only in the line in which they are specified). All other G codes are modal (active until another G code of the same group is specified).In this blog post, we present the ultimate CNC Machine G Code List, covering an extensive range of commands and functions. Additionally, we also provide a free downloadable PDF version of the list for easy reference.In CNC programming, there are 3 G-codes for selecting a plane during NC programming, which are used to define two axes: X, Y or Z. The plane selection is modal and is valid for everyone until you enter a different circular plane command. The 3 Plane selection G-Codes are: G17 for XY Plane G18 for XZ Plane G19 for YZ PlaneBasic G Codes G00 Move at Rapid speed G01 Feed in a Straight Line G02 Clockwise Arc G03 Counter Clockwise Arc G04 Time Dwell G28 Return Axis to Home G41 Cutter Compensation Left G42 Cutter Compensation Right G40 Cancel Cutter Compensation G43 Apply Tool Length Offset G54 to G59 Work Offsets .

list of fanuc g codes

G53 - Machine coordinate system setting; Mill and Lathe . G54~G59 - Workpiece coordinate system settings #1 t0 #6; Mill and Lathe . G61 - Exact stop check; Mill and Lathe . G65 - Custom macro call; Mill and Lathe . G70 - Finish cycle; Lathe . G71 - Rough turning cycle; Lathe . G72 - Rough facing cycle; Lathe . G73 - Irregular rough turning .G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

This document shows what are the G codes & M codes required for SINUMERIK programming in Turning and Milling applications. Whether it’s a basic part or a complex workpiece, the Siemens control system offers you a wealth of functionality with a very high degree of operator friendliness and manufacturing eficiency.G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from mach ine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.GPocket Guide and Reference Charts for CNC Machinists – Made in the U.S.A. –G codes from group B are of "one shot" type (active only in the line in which they are specified). All other G codes are modal (active until another G code of the same group is specified).

In this blog post, we present the ultimate CNC Machine G Code List, covering an extensive range of commands and functions. Additionally, we also provide a free downloadable PDF version of the list for easy reference.

In CNC programming, there are 3 G-codes for selecting a plane during NC programming, which are used to define two axes: X, Y or Z. The plane selection is modal and is valid for everyone until you enter a different circular plane command. The 3 Plane selection G-Codes are: G17 for XY Plane G18 for XZ Plane G19 for YZ Plane

Basic G Codes G00 Move at Rapid speed G01 Feed in a Straight Line G02 Clockwise Arc G03 Counter Clockwise Arc G04 Time Dwell G28 Return Axis to Home G41 Cutter Compensation Left G42 Cutter Compensation Right G40 Cancel Cutter Compensation G43 Apply Tool Length Offset G54 to G59 Work Offsets .

metal fabricators eureka ca

metal fabricators croton ny

list of all g codes

g code table listing

Forged metal tends to work. Even actual welding of the non-JB variety isn’t likely to work well in this case, goops and putties are a funny diversion but there’s just no chance.

cnc machine g code list pdf|cnc milling g codes list