sheet metal flat pattern layout calculator • The calculator will determine the total flat size of the sheet, optimizing material usage and ensuring precise part dimensions. Leverage this powerful calculator to enhance your sheet metal fabrication process, improve .

Our first priority is to provide you with the best work at the best cost, and to be your trusted source for almost any woodworking, metalworking, or Plastic need. We want to show you that we have the best to offer based on our experience and our associations within the industry.

0 · sheet metal flat pattern layout

1 · sheet metal flat pattern formula

2 · sheet metal flat length calculation

3 · sheet metal flat layout calculator

4 · sheet metal bending calculator free

5 · flat pattern layout calculator

6 · calculate k factor sheet metal

7 · blank size calculator sheet metal

$7.69

You can use this sheet metal flat pattern calculator to calculate this increase in length. For example when sheet metal of length “L” is bend. After bending, the total length (A+B) is larger .

K-factor Calculator for Sheet Metal Bending. K Factor in sheet metal bending is a .Mathematically k factor value is equal to the ratio of position of the neutral axis and .

Use SendCutSend’s bending calculator to input your desired material . Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It .

• The calculator will determine the total flat size of the sheet, optimizing material usage and ensuring precise part dimensions. Leverage this powerful calculator to enhance your sheet metal fabrication process, improve . The bend deduction is essential for accurately calculating the flat pattern of a sheet metal part before it is bent. It ensures that the final dimensions of the bent part match the design specifications.Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. In this article, we will discuss sheetmetal bend deduction, bend allowance, K-factor, Y-factor, and sheet metal flat pattern calculations.K-factor Calculator for Sheet Metal Bending. K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of neutral axis and sheet thickness.

With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet metal blank initial flat length, from the finished part measurements. You only have to insert .

Layout Calc is a program to calculate the flat sheet metal pattern needed to construct several different fabrications of certain dimensions. Choose the Layout Type On the left side dropdown .Sheet Metal and Plastic Bending Calculator. . This will result in the Sketch view (see below) showing the location the bend lines need to be placed in the flat pattern with the bend deduction taken into consideration. . and bend line . To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Essentially, you should calculate the centerline arc: (Outside Diameter – Thickness) x 3.1416 = Length of Plate Required (Inside Diameter + .

Unlock the power of advanced sheet metal calculations right at your fingertips. The Sheet Metal Flat Pattern Calculator is a comprehensive tool designed for engineers, fabricators, and designers who need quick and accurate flat pattern .

The curved steel cone calculator from Chicago Metal Rolled Products makes it easy to find the precise curved steel cone dimensions you need. . Sheet Metal Bending; Stainless Steel Bending; Calculators. Radius Calculator; . Flat Pattern Degrees: degrees .K Factor Calculator This calculator can be used for calculating k factor in sheet metal using reverse engineering method. Sheet Thickness, Material and machine affect the value of K Factor. K Factor Calculator Sheet Metal Flat Length Calculator Sheet Metal Flat Length can be calculated with this calculator. This calculator can be used for number [.]Miter Bend Calculator is used to generate Flat Pattern Layout Marking or Fabrication layout of Miter Bend, Segment Bend, Cut Bend or Fabricated Bend. . Miter Bend Flat Pattern Calculator. Bend Diameter : in mm. Bend Radius : in mm. Bend Angle : in Degree. (e.g 45, 90 etc.) . Sheet Metal Manufacturing Industry, Insulation Industry.Petal layout Calculator used to generate fabication layout markings or flat pattern layout markings of Sphere and Hemispherical Dish End Types. Sphere Petal Layout Calculator is very helpful in Pressure Vessel Fabarication, Storage tank Fabrication, sheet metal fabrication, process equipment fabrication and other types equipment fabrication .

How to make Flat Pattern or Fabrication Layout for Sheet Metal Works or Fabrication Shapes. . Previous Post Fabrication Flat Pattern Calculator App By Let’sFab. You Might Also Like. Pressure Vessels Heads February 13, 2020. Pressure Vessels Heads App by Let’sFab February 14, 2020. The second flat-blank-development example adds the two dimensions (from edge to the apex), and subtracts a bend deduction. In this case, the calculations use a complementary angle for the OSSB, and the dimensions are called from the edge to the apex—again, as specified in Figure 4.. Outside Setback (OSSB)The fact that you can take the software out "on the corner of the table" as you would take out a calculator on your smartphone is an incredible asset to be used on workshop and sites. . Aware of the difficulties encountered by sheet metalwork companies to perform their sheet metal flattening layout – an operation which consists in defining .

metal screw bracket clip

Overlap Normally, the flat pattern dimensions are are exact and dont have any extra material for overlapping the edges. If you want extra material on the edges of the cone then add here. The material is added evenly along the edge. If you enter 0.5" for overlap the shape of the original will be produced on the screen with the addition of red lines offset from each edge by 0.25.This calculator can be used to calculate various sheet metal design parameters for effective sheet metal design for press bensing. Blog For Engineers and Hobbyist. . Sheet Metal Flat Pattern Calculator; Convection Calculator : Convective Heat Transfer; K-factor Calculator for Sheet Metal Bending; Conductive Heat Transfer Calculator; For creating a cone from sheet metal or any flat material. Added the function of saving the development of a straight and truncated cone to a DXF file. Export the flat pattern as a dxf file, then you can open it with any CAD program like Acad. You can use the dxf file to cut the sheet on a laser or cnc machine.The speed and easiness of the sheet metal tool for flat patterns make it possible to process more drawings in the same time span. With this, the order time will decrease and products can be offered for a better competitive price. . Suitable for all materials. Whether you want to make a plate design from Aluminum, Steel or stainless steel .

K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of neutral axis and sheet thickness. During sheet metal part bending, the . The calculator generates DXF files that include two layers, one with the flat or unfolded pattern, and the other with a 3D wire-frame model of the transition. These are opened in the 2D software .Calculate patterns in seconds and get higher quality results. . Pipe Insulation & Metal Layout Handbook (English Version) .00. Buy. Buckaroos Insulator’s Handbook (English Version) . Since 2011 FLAT METAL PATTERNS has .

A: Flat pattern calculation is used to determine the amount of material required to create a specific shape from sheet metal. Q: How is flat pattern calculation used in sheet metal fabrication? A: Flat pattern calculation is used in sheet metal fabrication to create a template or pattern that can be used to cut and shape the sheet metal into .Flat Top Cone Calculator. Calculates the measurements for the pattern to construct a flat top cone. Length A (mm) Length B (mm) Length C (mm) Arc Angle = _ (degrees) Radius R1 = _ (mm) Radius R2 = _ (mm) Join my newsletter to keep updated! 💌 .This calculator will let you enter values and give you the results for the pattern to draw. Much easier than creating a 3D object then having Pepakura flatten it for you. . the pattern. I eventually used Google Sketchup to build a 3D image and imported it into Pepakura, printed out the flat design, taped/cut it onto my foam, and then cut out .

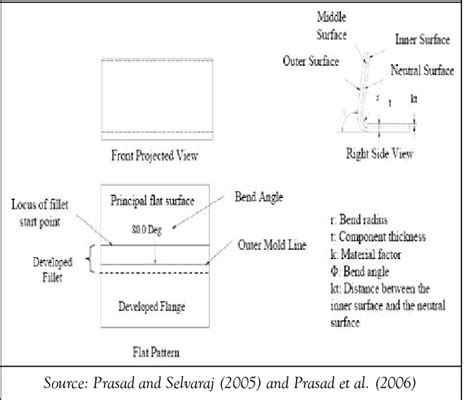

Use the elbow rule (# of pcs × 2 − 2) to find the number of gores.For our example, it is 4 × 2 − 2 = 6.Each end piece is made up of 1 gore and each middle piece is made up of two gores.; Use the angle of the elbow divided by the number of gores to find the miter angle. In our case, 90° ÷ 6 = 15°. Now that we know the miter angle is 15°, we can use an end gore and lay it out similar .Getting the flattened pattern of sheet metal fabrication parts by hand is time consuming, requires lots of knowledge, and it is prone to errors and not reliable.. There are lots of good sheet metal pattern development software programs out there, but they are expensive, with high subscription fees, with complex hardware requirements, and extensive user knowledge. Bend deduction (BD) is a critical factor in sheet metal fabrication, used to calculate the flat pattern length of a sheet metal part. It accounts for the material that is displaced during the bending process. This value is essential for ensuring that the final dimensions of the bent part are accurate. Key Terms and Notations How do you calculate the flat length of sheet metal? To calculate the flat length of sheet metal, you use the formula: Flat Length = [(π × Bend Radius × Bend Angle) / 180] + [(2 × Material Thickness) + Bend Allowance]. What is the formula for bending sheet metal? The formula for bending sheet metal involves using the K factor, bend radius .

Accurate Flat Pattern Layout: Outside Setback ensures that the flat pattern is dimensioned correctly, leading to precise bends and a part that meets the desired specifications. Proper Fit and Assembly: Accurate Outside Setback calculations ensure that bent parts fit together correctly during assembly, avoiding issues related to misalignment or .About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .The following terms are commonly used in sheet metal forming and flat pattern layout. Familiarity with these terms aids in understanding how bend calculations are used in a bending operation. . If no K chart is available, the K-factor can be calculated with a calculator by using the following formula: the K value is the tangent of one-half .

sheet metal flat pattern layout

Choose from compact benchtop CNCs to commercial-grade routers for projects of any scale. Start carving with this robust and easy-to-use hobbyist CNC router. No prior CNC experience required! Versatile and professional CNC carving. Unleash your wildest creative dreams with a pro CNC!

sheet metal flat pattern layout calculator|sheet metal flat pattern layout