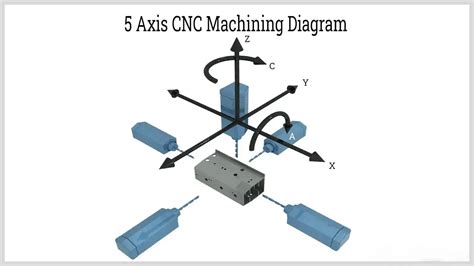

cnc machine axis names Four axes on a CNC machine add an extra cutting direction, which increases precision. The fifth axis further improves the accuracy of the machine, but the cost of the five-axis CNC machine makes it too expensive for most businesses.

Aluminum CNC Machining Parts Manufacturers, Factory, Suppliers From China, We can do your customized order to meet your own satisfactory! Our company sets up several departments, including production department, sales department, quality control department and sevice center, etc.

0 · cnc with rotary axis

1 · cnc machine axis locations diagram

2 · cnc machine axis direction

3 · cnc axis explained

4 · cnc axis chart

5 · axis identification in cnc machine

6 · 4 axis cnc milling machines

7 · 4 axis cnc machine cost

MOQ of 24 custom bento lunch boxes. Nicety specializes in producing custom .

In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the . In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the role and significance of the X, Y, Z, and additional axes, as well as the potential of multi-axis and specialized machines, you now possess the knowledge necessary .

house tyrell metal

Four- and five-axis CNC milling machines have one or two rotating axes in addition to the three axes that move the table. The figure above shows the main control parts of a CNC mill, including the human-machine interface (computer), controller, amplifier, encoder, motor, ball screw, and guide rail.CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth). Four axes on a CNC machine add an extra cutting direction, which increases precision. The fifth axis further improves the accuracy of the machine, but the cost of the five-axis CNC machine makes it too expensive for most businesses. There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool along the length of the workpiece.

Here’s a quick look into the most common CNC machine axis layouts—3-axis, 4-axis, and 5-axis—and see how they stack up. The 3-axis CNC machine lays the foundation for most CNC machining. As the name suggests, it can .

cnc with rotary axis

The moving axes of machine tools are assigned names (addresses). These names are referred to as addresses or axis names. Axis names are determined according to the machine tool configuration and construction. The naming rules must comply with standards such as the ISO 841 standards.In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.

CNC (Computer Numerical Control) machines utilize multiple axes to perform precise cutting and shaping operations. The number of axes directly influences the machine’s ability to manipulate the workpiece, the complexity of parts it . In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the role and significance of the X, Y, Z, and additional axes, as well as the potential of multi-axis and specialized machines, you now possess the knowledge necessary .

Four- and five-axis CNC milling machines have one or two rotating axes in addition to the three axes that move the table. The figure above shows the main control parts of a CNC mill, including the human-machine interface (computer), controller, amplifier, encoder, motor, ball screw, and guide rail.CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).

Four axes on a CNC machine add an extra cutting direction, which increases precision. The fifth axis further improves the accuracy of the machine, but the cost of the five-axis CNC machine makes it too expensive for most businesses.

There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool along the length of the workpiece. Here’s a quick look into the most common CNC machine axis layouts—3-axis, 4-axis, and 5-axis—and see how they stack up. The 3-axis CNC machine lays the foundation for most CNC machining. As the name suggests, it can . The moving axes of machine tools are assigned names (addresses). These names are referred to as addresses or axis names. Axis names are determined according to the machine tool configuration and construction. The naming rules must comply with standards such as the ISO 841 standards.

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.

house plans inside metal buildings

cnc machine axis locations diagram

cnc machine axis direction

house og color gold metal flake

cnc axis explained

Utility owns the meter. You own (and are therefore responsible for) the meter base and feeders.

cnc machine axis names|cnc machine axis locations diagram