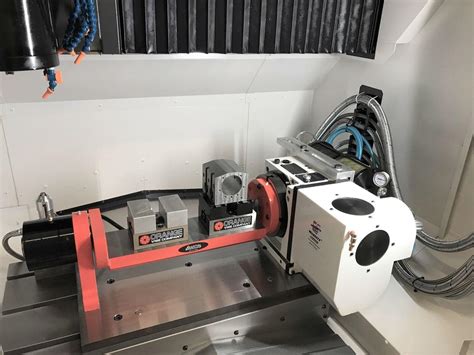

4 axis cnc design parts The key components of a 4-axis CNC machine include the machine bed, spindle, chuck or collet, and the rotary axis. The spindle holds the cutting tool and moves along the X, Y, and Z axes, while the rotary axis rotates the workpiece. Aluminum CNC Services offers high quality CNC machining services for aluminum parts. With our state-of-the-art facility, we are able to produce precise and accurate parts at a competitive price. As a factory, we prioritize efficiency and fast turnaround times without sacrificing quality.

0 · cnc 4th axis for sale

1 · 4th axis for cnc mill

2 · 4 axis hobby cnc

3 · 4 axis desktop cnc mill

4 · 4 axis desktop cnc

5 · 4 axis cnc mill cost

6 · 4 axis cnc machine price

7 · 4 axis cnc for sale

Wholesale China ISO Certificated Custom Rapid Prototype Anodized Stainless Steel CNC Machining Parts Service

4-axis CNC machining is a versatile process for machining different components ranging from small electronic parts to large aerospace machined parts. They are also suitable for handling various CNC machining materials .4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup.

The key components of a 4-axis CNC machine include the machine bed, spindle, chuck or collet, and the rotary axis. The spindle holds the cutting tool and moves along the X, Y, and Z axes, while the rotary axis rotates the workpiece. All CNC machines are built around these basic axes for every hole, cut and feature machined. Today, more advanced CNC machines add a fourth or fifth axis to expand even more machining without resetting the workpiece. In .The basic principles of 4-axis CNC machining involve using CAD (Computer-Aided Design) software to create a digital model of the desired part or component. This model is then converted into machine code, instructing the CNC machine .

4-axis CNC machining is a versatile process for machining different components ranging from small electronic parts to large aerospace machined parts. They are also suitable for handling various CNC machining materials and part sizes. In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.

4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup.

4-axis CNC machining allows for greater precision and versatility in the production of complex parts. The fourth axis, also known as the A-axis, enables the machine to rotate the part being worked on, allowing for more intricate cuts and contours.The key components of a 4-axis CNC machine include the machine bed, spindle, chuck or collet, and the rotary axis. The spindle holds the cutting tool and moves along the X, Y, and Z axes, while the rotary axis rotates the workpiece. All CNC machines are built around these basic axes for every hole, cut and feature machined. Today, more advanced CNC machines add a fourth or fifth axis to expand even more machining without resetting the workpiece. In fact, the first step in .

The basic principles of 4-axis CNC machining involve using CAD (Computer-Aided Design) software to create a digital model of the desired part or component. This model is then converted into machine code, instructing the CNC machine on how to .

Making something with 4-axis CNC machining involves several key steps, from early design to finished product: Engineers first make a 3D model in CAD software. This virtual model matches desired shape and size of real part. It .Designing for CNC machining can be improved by simply following these rules and guidelines. Our design-for-manufacturability guide can also help you trim costs, shorten leadtimes, and improve your parts’ overall quality. This paper covers various aspects of CAD designs and significant considerations for designing features for CNC machining. When designing parts for CNC machining, it’s essential to keep the DFM principles in mind. These principles are based on the idea of designing parts that are easy to manufacture, and they can help you to avoid common pitfalls and ensure that your parts are optimized for CNC machining. Some of the key DFM principles to keep in mind include: 4-axis CNC machining is a versatile process for machining different components ranging from small electronic parts to large aerospace machined parts. They are also suitable for handling various CNC machining materials and part sizes.

In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.

4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup. 4-axis CNC machining allows for greater precision and versatility in the production of complex parts. The fourth axis, also known as the A-axis, enables the machine to rotate the part being worked on, allowing for more intricate cuts and contours.The key components of a 4-axis CNC machine include the machine bed, spindle, chuck or collet, and the rotary axis. The spindle holds the cutting tool and moves along the X, Y, and Z axes, while the rotary axis rotates the workpiece.

All CNC machines are built around these basic axes for every hole, cut and feature machined. Today, more advanced CNC machines add a fourth or fifth axis to expand even more machining without resetting the workpiece. In fact, the first step in .

The basic principles of 4-axis CNC machining involve using CAD (Computer-Aided Design) software to create a digital model of the desired part or component. This model is then converted into machine code, instructing the CNC machine on how to .

Making something with 4-axis CNC machining involves several key steps, from early design to finished product: Engineers first make a 3D model in CAD software. This virtual model matches desired shape and size of real part. It .Designing for CNC machining can be improved by simply following these rules and guidelines. Our design-for-manufacturability guide can also help you trim costs, shorten leadtimes, and improve your parts’ overall quality. This paper covers various aspects of CAD designs and significant considerations for designing features for CNC machining.

cnc 4th axis for sale

roller bending sheet metal

romex to 3 4 pvc junction box

Metal stamping is the manufacturing process in which a strip of sheet metal is fed through one or more die and tool sets to apply pressure, re-forming and cutting the piece into a desired shape.

4 axis cnc design parts|4 axis cnc mill cost