cnc lathe machine standard operating procedure Operating a CNC lathe machine requires precision, expertise, and adherence to standard operating procedures (SOPs). To ensure your team operates the machine safely and . This PawHut metal chicken run is extra-long and wide, allowing a multiplicity of chickens. The roof provides stronger protection against rain while ensuring UV resistance. The design allows conjunction with wooden cages when you want real walls.

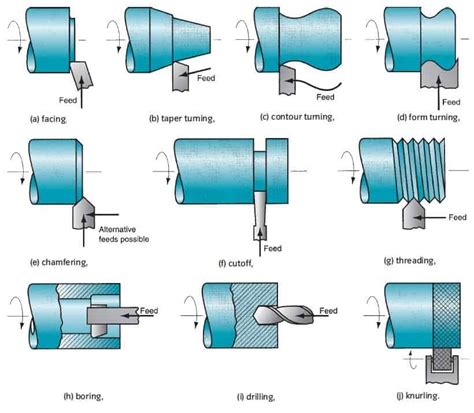

0 · turning operations on lathe machine

1 · turning operation lathe

2 · turning lathe diagram

3 · cnc turning lathe machine

4 · cnc lathe setup

5 · cnc lathe machine operations

6 · basic turning operations

7 · application of cnc lathe machine

With over 10 000 parts in stock for the Classic Volvo PV 544/210, Volvo Amazon, Volvo 1800 S/E/ES models, Volvo 140/164 & Volvo 240/260. CVR are today one of the leading sources for Classic Volvo parts worldwide. Make your classic Volvo restoration a success!

Operating a CNC lathe machine requires precision, expertise, and adherence to standard operating procedures (SOPs). To ensure your team operates the machine safely and .All stock must be properly secured in the lathe chuck or mounted prior to the machining process taking place. Use the correct sized clamp or vise for the stock being machined. Turn the chuck .

1997 dodge grand caravan wiper motor and junction box

Locate and ensure you are familiar with the operation of the ON/OFF start and E-Stop. Ensure all guards are in place. Check that the job is clamped tight in the chuck. Remove all tools from the .This standard operating procedure (SOP) provides comprehensive guidelines for operating a CNC machine and outlines the key steps to be followed during machine setup, programming, and .During operation, keep hands a safe distance away and only use adjustment tools on lathe to maneuver work piece. Know the location of start and stop switches or buttons and keep the .

Though the CNC lathe machine’s operations are mechanical, it’s designed for automated precision machining. The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a .

1993 s10 metal wibdow track bracket

tools or pieces of equipment: Mill, Lathe, Planer, Drill Press, Pedestal Grinder, & Band Saw. GENERAL SAFETY TIPS • Safety glasses with side shields must be worn at all times. Ever wondered how to safely and efficiently operate a lathe? This article breaks down the essential procedures and precautions every operator must follow. From pre-operation inspections to precise shutdown protocols, it covers all .Operating a CNC lathe machine requires precision, expertise, and adherence to standard operating procedures (SOPs). To ensure your team operates the machine safely and efficiently, ClickUp's CNC Lathe Machine SOP Template is here to help!All stock must be properly secured in the lathe chuck or mounted prior to the machining process taking place. Use the correct sized clamp or vise for the stock being machined. Turn the chuck or faceplate by hand to ensure there is no binding or danger of the work striking any part of the lathe.

1994 ford ranger power distribution box diagram

Locate and ensure you are familiar with the operation of the ON/OFF start and E-Stop. Ensure all guards are in place. Check that the job is clamped tight in the chuck. Remove all tools from the bed slides of the machine. Ensure correct speed machining process is selected. Remove the chuck key before starting the lathe.

This standard operating procedure (SOP) provides comprehensive guidelines for operating a CNC machine and outlines the key steps to be followed during machine setup, programming, and maintenance. Step 1: Machine Setup. 1. Ensure a clean .During operation, keep hands a safe distance away and only use adjustment tools on lathe to maneuver work piece. Know the location of start and stop switches or buttons and keep the drill and other materials. Use only properly sharpened drill bits, sockets and chucks in good condition. Though the CNC lathe machine’s operations are mechanical, it’s designed for automated precision machining. The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool.The document provides standard operating procedures for using a lathe. It outlines several safety steps: [1] securely clamp stock before machining, [2] check for binding or risk of contact, [3] ensure the tool will not hit the chuck, [4] check clearances before starting.

With a CNC lathe, the tooling operates according to a program written and uploaded to the machine, allowing for highly precise and repeatable production. How does a CNC lathe work? Read on to learn the answer — as well as some tips for operation in the process.

tools or pieces of equipment: Mill, Lathe, Planer, Drill Press, Pedestal Grinder, & Band Saw. GENERAL SAFETY TIPS • Safety glasses with side shields must be worn at all times.

Ever wondered how to safely and efficiently operate a lathe? This article breaks down the essential procedures and precautions every operator must follow. From pre-operation inspections to precise shutdown protocols, it covers all .Operating a CNC lathe machine requires precision, expertise, and adherence to standard operating procedures (SOPs). To ensure your team operates the machine safely and efficiently, ClickUp's CNC Lathe Machine SOP Template is here to help!

turning operations on lathe machine

turning operation lathe

All stock must be properly secured in the lathe chuck or mounted prior to the machining process taking place. Use the correct sized clamp or vise for the stock being machined. Turn the chuck or faceplate by hand to ensure there is no binding or danger of the work striking any part of the lathe.Locate and ensure you are familiar with the operation of the ON/OFF start and E-Stop. Ensure all guards are in place. Check that the job is clamped tight in the chuck. Remove all tools from the bed slides of the machine. Ensure correct speed machining process is selected. Remove the chuck key before starting the lathe.

This standard operating procedure (SOP) provides comprehensive guidelines for operating a CNC machine and outlines the key steps to be followed during machine setup, programming, and maintenance. Step 1: Machine Setup. 1. Ensure a clean .

turning lathe diagram

During operation, keep hands a safe distance away and only use adjustment tools on lathe to maneuver work piece. Know the location of start and stop switches or buttons and keep the drill and other materials. Use only properly sharpened drill bits, sockets and chucks in good condition. Though the CNC lathe machine’s operations are mechanical, it’s designed for automated precision machining. The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool.The document provides standard operating procedures for using a lathe. It outlines several safety steps: [1] securely clamp stock before machining, [2] check for binding or risk of contact, [3] ensure the tool will not hit the chuck, [4] check clearances before starting.

1989 skyline aljo power distribution box

1995 gmc 1500 fuse box mounting bracket

30 amp Junction Box; 60 amp Junction Box; . Wago Junction Boxes; Hager Ahsley Junction Boxes; Wiska Boxes; Gewiss Boxes; Electrical Connectors. Click Flow Connectors; Wago Connectors. Wago 221; Wago 222; Henley Blocks; Connector Blocks; Waterproof Cable Connectors; Occupancy Sensors. PIR Sensors;

cnc lathe machine standard operating procedure|application of cnc lathe machine