electric vehicle battery box bonding adhesive No traditional structural adhesive offers performance, processing and sustainability demands needed to meet EV battery box requirements.

Fieldbus Junction Boxes with Integrated Diagnostics 11/13 – Junction boxes for Foundation Fieldbus and Profibus-PA can be used worldwide in all Ex zones

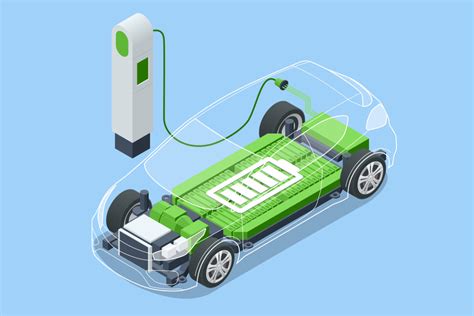

0 · electric vehicle battery design

1 · electric vehicle battery applications

2 · electric car battery adhesive

$6,141.52

Manufacturers rely on high-performance bonding adhesives explicitly designed for EV battery boxes to achieve these goals. This article delves into EV battery box bonding .Assembling electric vehicle (EV) battery boxes using structural adhesives instead of mechanical fasteners not only results in process efficiencies but can help installed boxes perform better. Here are five ways how.AR’s portfolio of pressure sensitive adhesives is designed for a broad range of applications throughout the cell, module, and pack, including electrode and conductive bonding, . The primary benefit of using adhesives between battery cells is bonding. These tapes can be used to bond cells together in much the same way a liquid adhesive would. With .

high-voltage battery systems for Electric and Hybrid Electric Vehicles, few application areas are as demanding for adhesives as battery bonding. 3M™ Scotch-Weld™ Structural Adhesives .No traditional structural adhesive offers performance, processing and sustainability demands needed to meet EV battery box requirements. Structural adhesives are used in EV battery packs to create bonds that can withstand various environmental conditions and mechanical loads. These adhesives provide shear and tensile strength to increase protection against .Fix fast & Bond durable: based on fast-fixing cyanoacrylates, in combination with structural adhesives like methyl methacrylate (MMA) or polyurethane (PU) technologies, these adhesives provide a complete and innovative solution to .

Structural adhesives for battery packs optimize housing integrity and crash performance. Henkel's solutions can be applied cost-efficiently by robot, and are suitable for both aluminum and multi-metal frames and structures. Structural . EV battery adhesives connect the individual components while serving other roles like electrical insulation or conductors. These adhesives join individual battery cells, assemble battery modules, fix modules into packs, and . Manufacturers rely on high-performance bonding adhesives explicitly designed for EV battery boxes to achieve these goals. This article delves into EV battery box bonding adhesive, exploring its importance, types, advantages, and future trends in electric vehicles. The EV battery box is more than just a protective casing for the battery cells.

Assembling electric vehicle (EV) battery boxes using structural adhesives instead of mechanical fasteners not only results in process efficiencies but can help installed boxes perform better. Here are five ways how.AR’s portfolio of pressure sensitive adhesives is designed for a broad range of applications throughout the cell, module, and pack, including electrode and conductive bonding, encapsulation, device wrapping, shock absorbency, and process aids. The primary benefit of using adhesives between battery cells is bonding. These tapes can be used to bond cells together in much the same way a liquid adhesive would. With the tape, however, there are many added benefits:

high-voltage battery systems for Electric and Hybrid Electric Vehicles, few application areas are as demanding for adhesives as battery bonding. 3M™ Scotch-Weld™ Structural Adhesives offer advanced solutions for bonding dissimilar materials, and our expertise helps you apply them.No traditional structural adhesive offers performance, processing and sustainability demands needed to meet EV battery box requirements. Structural adhesives are used in EV battery packs to create bonds that can withstand various environmental conditions and mechanical loads. These adhesives provide shear and tensile strength to increase protection against external forces such as impacts, vibrations, and loads. With structural adhesives, battery components are stronger together.Fix fast & Bond durable: based on fast-fixing cyanoacrylates, in combination with structural adhesives like methyl methacrylate (MMA) or polyurethane (PU) technologies, these adhesives provide a complete and innovative solution to ensuring proper, durable EV battery pack integration. In particular, they possess:

electric vehicle battery design

Structural adhesives for battery packs optimize housing integrity and crash performance. Henkel's solutions can be applied cost-efficiently by robot, and are suitable for both aluminum and multi-metal frames and structures. Structural Bonding, Mobility Alliance. Metal Pretreatment. EV battery adhesives connect the individual components while serving other roles like electrical insulation or conductors. These adhesives join individual battery cells, assemble battery modules, fix modules into packs, and act as electrical conduits between different sections. Manufacturers rely on high-performance bonding adhesives explicitly designed for EV battery boxes to achieve these goals. This article delves into EV battery box bonding adhesive, exploring its importance, types, advantages, and future trends in electric vehicles. The EV battery box is more than just a protective casing for the battery cells.Assembling electric vehicle (EV) battery boxes using structural adhesives instead of mechanical fasteners not only results in process efficiencies but can help installed boxes perform better. Here are five ways how.

AR’s portfolio of pressure sensitive adhesives is designed for a broad range of applications throughout the cell, module, and pack, including electrode and conductive bonding, encapsulation, device wrapping, shock absorbency, and process aids.

The primary benefit of using adhesives between battery cells is bonding. These tapes can be used to bond cells together in much the same way a liquid adhesive would. With the tape, however, there are many added benefits:

high-voltage battery systems for Electric and Hybrid Electric Vehicles, few application areas are as demanding for adhesives as battery bonding. 3M™ Scotch-Weld™ Structural Adhesives offer advanced solutions for bonding dissimilar materials, and our expertise helps you apply them.No traditional structural adhesive offers performance, processing and sustainability demands needed to meet EV battery box requirements.

Structural adhesives are used in EV battery packs to create bonds that can withstand various environmental conditions and mechanical loads. These adhesives provide shear and tensile strength to increase protection against external forces such as impacts, vibrations, and loads. With structural adhesives, battery components are stronger together.Fix fast & Bond durable: based on fast-fixing cyanoacrylates, in combination with structural adhesives like methyl methacrylate (MMA) or polyurethane (PU) technologies, these adhesives provide a complete and innovative solution to ensuring proper, durable EV battery pack integration. In particular, they possess:

Structural adhesives for battery packs optimize housing integrity and crash performance. Henkel's solutions can be applied cost-efficiently by robot, and are suitable for both aluminum and multi-metal frames and structures. Structural Bonding, Mobility Alliance. Metal Pretreatment.

brushed stainless steel filing cabinets

electric vehicle battery applications

Etasis Machine Tools is a Turkish brand specialized in CNC manufacturing. Our dedication to innovation and continuous improvement has helped us become a leading provider of CNC laser, turning and milling machines serving customers around the world, mostly in Europe and Turkey.

electric vehicle battery box bonding adhesive|electric vehicle battery design