define cnc part programming CNC programming involves you or a fellow colleague using computer-aided manufacturing (CAM) software to convert a CAD file into a language that a CNC machine can read, whether it’s a cutting, milling, or . Have you ever noticed a star adorning the exterior of a house and wondered about its significance? These stars are seldom the same, often seen in various colors, sizes, and materials — they are not just decorative elements; they carry a wealth of history and meaning.

0 · manual cnc programming for beginners

1 · different types of cnc programming

2 · cnc programming website

3 · cnc programming full form

4 · cnc programming and machining

5 · cnc machine programming and operation

6 · cnc lathe programming for beginners

7 · basic cnc programming for beginners

A utility box, sometimes referred to as an electrical box, is an essential component in electrical systems. Not only does it protect wires and .

manual cnc programming for beginners

CNC programming involves you or a fellow colleague using computer-aided manufacturing (CAM) software to convert a CAD file into a language that a CNC machine can read, whether it’s a cutting, milling, or .

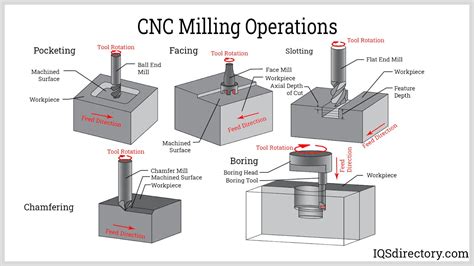

CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such as cutting, milling , . CNC programming involves you or a fellow colleague using computer-aided manufacturing (CAM) software to convert a CAD file into a language that a CNC machine can read, whether it’s a cutting, milling, or turning tool (although they . CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC milling machines, CNC lathes , and 3D printers.

slaves metal gloves boxing

different types of cnc programming

In modern CNC systems, the design of a mechanical part and its manufacturing program are highly automated. The part's mechanical dimensions are defined using CAD software and then translated into manufacturing directives by CAM software.

CNC programming refers to the process of using software to develop CNC machine instructions. These instructions control how the CNC machine moves while interacting with the work piece. Popular CNC machines that work with CNC programming are CNC lathes and CNC milling machines. CNC programming is the process of creating instructions for CNC machines using specialized software. These instructions control the machine’s movements as it interacts with the workpiece, enabling precise and automated operations on a variety of materials. CNC programming provides automation, cost savings, excellent machining quality, flexibility, reduced production time, and a host of other benefits to manufacturers. It is an incredibly versatile industrial solution that can be used with wood, metal, plastics, composites, glass, foam, and more.CNC machine programming offers a systematic approach to controlling automated equipment with precision and efficiency. It involves converting design concepts into a language that computer-controlled machinery, such as mills, lathes, or routers, understands.

CNC programming controls routers, mills, lathes, mill-turn and turn-mill machines, multi-tasking centers, wire EDMs, and industrial robots. Generally, instructions to any CNC machine are delivered manually or digitally. The digital method includes offline Computer Aided Manufacturing (CAM) Software. What are the types of CNC programming methods?

The process of creating a part on a CNC starts with CNC programming, where engineers generate a set of instructions based on a design. These instructions are then handed over to CNC operators who translate these instructions into machine-specific codes, as different machines require different programming.CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such as cutting, milling , . CNC programming involves you or a fellow colleague using computer-aided manufacturing (CAM) software to convert a CAD file into a language that a CNC machine can read, whether it’s a cutting, milling, or turning tool (although they .

CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC milling machines, CNC lathes , and 3D printers.In modern CNC systems, the design of a mechanical part and its manufacturing program are highly automated. The part's mechanical dimensions are defined using CAD software and then translated into manufacturing directives by CAM software. CNC programming refers to the process of using software to develop CNC machine instructions. These instructions control how the CNC machine moves while interacting with the work piece. Popular CNC machines that work with CNC programming are CNC lathes and CNC milling machines.

small 110v surface mount junction box

CNC programming is the process of creating instructions for CNC machines using specialized software. These instructions control the machine’s movements as it interacts with the workpiece, enabling precise and automated operations on a variety of materials.

CNC programming provides automation, cost savings, excellent machining quality, flexibility, reduced production time, and a host of other benefits to manufacturers. It is an incredibly versatile industrial solution that can be used with wood, metal, plastics, composites, glass, foam, and more.

CNC machine programming offers a systematic approach to controlling automated equipment with precision and efficiency. It involves converting design concepts into a language that computer-controlled machinery, such as mills, lathes, or routers, understands.

CNC programming controls routers, mills, lathes, mill-turn and turn-mill machines, multi-tasking centers, wire EDMs, and industrial robots. Generally, instructions to any CNC machine are delivered manually or digitally. The digital method includes offline Computer Aided Manufacturing (CAM) Software. What are the types of CNC programming methods?

cnc programming website

Getting your hands on some of the best CNC routers for at home is now easier than ever, with numerous options at your disposal. In this article, we’ll guide you through a comprehensive list of the best home CNC machines currently available in the market.

define cnc part programming|basic cnc programming for beginners