cnc machine shop rate calculator Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs. Wood screws are used to secure wood, while metal screws fasten sheet metal. The two types are identical in every way except for the threads they are made of.

0 · machine shop hourly rate calculator

1 · machine shop hourly rate

2 · how expensive is cnc machining

3 · cnc machining hourly rate

4 · cnc machining cost

5 · cnc machine hourly rate calculator

6 · cnc cutting cost

7 · calculating machine cost per hour

These outdoor showers are constructed from top quality cedar tongue and groove – the perfect wood due to its durability against extreme weather and natural resistance to decay – or choose durable and easy to maintain PVC. Pick and choose customizable features from sizes to .

The CNC Machine Hourly Rate Calculator is an essential tool for accurately estimating costs in CNC machining. By inputting relevant data, shops can determine the total .Start by determining the hourly rate of your CNC machine, factoring in its purchase . Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs.I’ve noticed the shops around us do about an hour though. There’s one shop near us that makes blowers and very large machined parts and they’re in the .

It’s tough to know how much to charge for your services. As a CNC Job Shop (and product manufacturer), we’ve been through that growing pain. To help out we made a quick way to figure this out for yourself. Use our free .

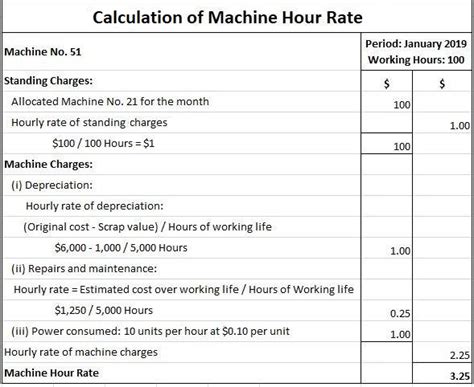

In this article, we calculate hourly rate by summing all our monthly costs and dividing by the number of machinist hours worked. I’ve chosen a shop of 9 staff consisting of 5 machinists and 4 support staff.

Since many shops will utilize an hourly rate as a basis for charging for machining time, this post is dedicated to some helpful guidelines on how to calculate that machining hourly rate. Below are some points we consider important when .

Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours. Add the hourly wage of skilled operators, including benefits and taxes. Setting down to calculate your CNC hourly rate is key to your future success. So how do you find your hourly in this daunting task? Well, there are a few different methods we can work through to help find that hourly rate that .

Machinists determine machine shop rates, commonly known as the machining charge per hour, by dividing the price of CNC machines by their total yearly usage hours. Below is a table that compares the prices of various types . The CNC Machine Hourly Rate Calculator is an essential tool for accurately estimating costs in CNC machining. By inputting relevant data, shops can determine the total cost of ownership and the final hourly cost with labor.

Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs.

I’ve noticed the shops around us do about an hour though. There’s one shop near us that makes blowers and very large machined parts and they’re in the 0 - 0 range depending on how much the job should cost to run. It’s tough to know how much to charge for your services. As a CNC Job Shop (and product manufacturer), we’ve been through that growing pain. To help out we made a quick way to figure this out for yourself. Use our free Calculator below to find out your Cost and Charge Rates for your Shop.In this article, we calculate hourly rate by summing all our monthly costs and dividing by the number of machinist hours worked. I’ve chosen a shop of 9 staff consisting of 5 machinists and 4 support staff.

Since many shops will utilize an hourly rate as a basis for charging for machining time, this post is dedicated to some helpful guidelines on how to calculate that machining hourly rate. Below are some points we consider important when calculating the hourly rate for a particular machine. Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours. Add the hourly wage of skilled operators, including benefits and taxes. Setting down to calculate your CNC hourly rate is key to your future success. So how do you find your hourly in this daunting task? Well, there are a few different methods we can work through to help find that hourly rate that makes the perfect sense.

Machinists determine machine shop rates, commonly known as the machining charge per hour, by dividing the price of CNC machines by their total yearly usage hours. Below is a table that compares the prices of various types of CNC machines. Companies such as JetCrafted simplify the pricing and operational costs of CNC machines by offering a CNC Machine Hourly Rate Calculator. This tool considers various factors to provide a precise estimate, helping manufacturers and machine shop owners gauge costs with greater accuracy. The CNC Machine Hourly Rate Calculator is an essential tool for accurately estimating costs in CNC machining. By inputting relevant data, shops can determine the total cost of ownership and the final hourly cost with labor. Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs.

I’ve noticed the shops around us do about an hour though. There’s one shop near us that makes blowers and very large machined parts and they’re in the 0 - 0 range depending on how much the job should cost to run. It’s tough to know how much to charge for your services. As a CNC Job Shop (and product manufacturer), we’ve been through that growing pain. To help out we made a quick way to figure this out for yourself. Use our free Calculator below to find out your Cost and Charge Rates for your Shop.In this article, we calculate hourly rate by summing all our monthly costs and dividing by the number of machinist hours worked. I’ve chosen a shop of 9 staff consisting of 5 machinists and 4 support staff.Since many shops will utilize an hourly rate as a basis for charging for machining time, this post is dedicated to some helpful guidelines on how to calculate that machining hourly rate. Below are some points we consider important when calculating the hourly rate for a particular machine.

Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours. Add the hourly wage of skilled operators, including benefits and taxes. Setting down to calculate your CNC hourly rate is key to your future success. So how do you find your hourly in this daunting task? Well, there are a few different methods we can work through to help find that hourly rate that makes the perfect sense.

Machinists determine machine shop rates, commonly known as the machining charge per hour, by dividing the price of CNC machines by their total yearly usage hours. Below is a table that compares the prices of various types of CNC machines.

simulador torno cnc fanuc

This video shows how to make a cover for your electrical panel box that has a door and lock. The whole process is shown in detail, and the result looks great. In addition to improving the appearance of an electrical panel box, a cover can also help to protect the box from damage.Check out our wood electrical box selection for the very best in unique or custom, handmade pieces from our wall hangings shops.

cnc machine shop rate calculator|cnc machining cost