electrical trough vs junction box Pull Boxes and Junction Boxes differences between pull boxes in electrical installations. Understand functions, sizes, and applications. A variety of seams are used to connect pieces of sheet metal in construction, auto body creation and fine art sculpture. The type of seam used depends largely on the application; some seams .

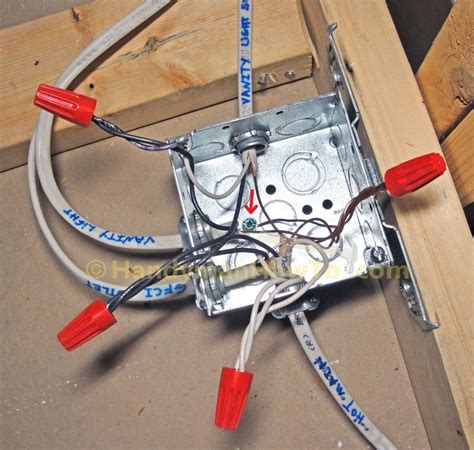

0 · junction box wiring diagram

1 · junction box vs electrical box

2 · electrical pull boxes

3 · electrical junction box vs pull box

4 · electrical junction box sizes

5 · electrical junction box installation

6 · electrical junction box

7 · e-abel junction box

Metal fabricators often start with stock metal components, such as sheet metal, metal rods, metal billets, and metal bars to create a new product. Specialized metal fabricators are called fabrication shops.

You'll want to look at article 376 for your trough information and article 312 for pull boxes/ junction boxes. Pull Boxes and Junction Boxes differences between pull boxes in electrical installations. Understand functions, sizes, and applications. A pull box describes an electrical box that gives access to pull electrical cables through non-metallic or metallic raceways and conduit. They give you a means to pull .As a rule of thumb, pull boxes are used when conductors are pulled straight through a box and terminated down-stream. On the other hand, junction boxes can be used for splicing or tapping .

Junction boxes join multiple wires and are used in residential and commercial spaces for organization and code compliance. Choosing the Right Electrical Box for Your Project. Selecting the appropriate electrical box .

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and . The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG . A junction box is a standard electrical box that encloses wire splices and contains no device (like a receptacle). What is a Type 1 junction box vs. a Type 2 junction box? The type 2 junction box is only for indoor use. You'll want to look at article 376 for your trough information and article 312 for pull boxes/ junction boxes.

Learn the key differences between pull boxes and junction boxes, their functions, and when to use each in electrical installations for safety and efficiency. Pull Boxes and Junction Boxes differences between pull boxes in electrical installations. Understand functions, sizes, and applications. A pull box describes an electrical box that gives access to pull electrical cables through non-metallic or metallic raceways and conduit. They give you a means to pull conductors across an extended distance without putting too much tension on the cable or insulation.As a rule of thumb, pull boxes are used when conductors are pulled straight through a box and terminated down-stream. On the other hand, junction boxes can be used for splicing or tapping conductors. Field experience has taught electricians that it is not wise to skimp on the size or number of boxes needed in a run.

12 ga sheet metal weight

Junction boxes join multiple wires and are used in residential and commercial spaces for organization and code compliance. Choosing the Right Electrical Box for Your Project. Selecting the appropriate electrical box depends on several factors, including construction, wiring method, devices, location, and safety. Type of Construction You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ).

A junction box is a standard electrical box that encloses wire splices and contains no device (like a receptacle). What is a Type 1 junction box vs. a Type 2 junction box? The type 2 junction box is only for indoor use. An LB (LL, LR, etc) is a valid access point for pulling, all by itself, no need for a junction box instead. In general, if not doing something like changing from cable to wires in conduit, a continuous run is preferable, as it has fewer junctions to potentially fail. You'll want to look at article 376 for your trough information and article 312 for pull boxes/ junction boxes.

Learn the key differences between pull boxes and junction boxes, their functions, and when to use each in electrical installations for safety and efficiency.

Pull Boxes and Junction Boxes differences between pull boxes in electrical installations. Understand functions, sizes, and applications. A pull box describes an electrical box that gives access to pull electrical cables through non-metallic or metallic raceways and conduit. They give you a means to pull conductors across an extended distance without putting too much tension on the cable or insulation.As a rule of thumb, pull boxes are used when conductors are pulled straight through a box and terminated down-stream. On the other hand, junction boxes can be used for splicing or tapping conductors. Field experience has taught electricians that it is not wise to skimp on the size or number of boxes needed in a run. Junction boxes join multiple wires and are used in residential and commercial spaces for organization and code compliance. Choosing the Right Electrical Box for Your Project. Selecting the appropriate electrical box depends on several factors, including construction, wiring method, devices, location, and safety. Type of Construction

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ). A junction box is a standard electrical box that encloses wire splices and contains no device (like a receptacle). What is a Type 1 junction box vs. a Type 2 junction box? The type 2 junction box is only for indoor use.

junction box wiring diagram

junction box vs electrical box

12 x 12 metal junction box

What is an Electrical Box? An electrical box, often referred to as a junction box, is a container that houses electrical connections and wiring. These boxes protect electrical connections from environmental factors and accidental damage, ensuring .

electrical trough vs junction box|electrical junction box installation