cnc machine enclosure venting There are two major categories of enclosure ventilation: passive and forced air. 1. Passive ventilation uses non-mechanical design elements, such as ventilation holes cut . See more In this article series about septic system drop boxes we describe the best procedures for locating and inspecting, repairing or replacing the septic drainfield distribution box, or the "D-box" or "Splitter box".

0 · well ventilated instrument enclosure

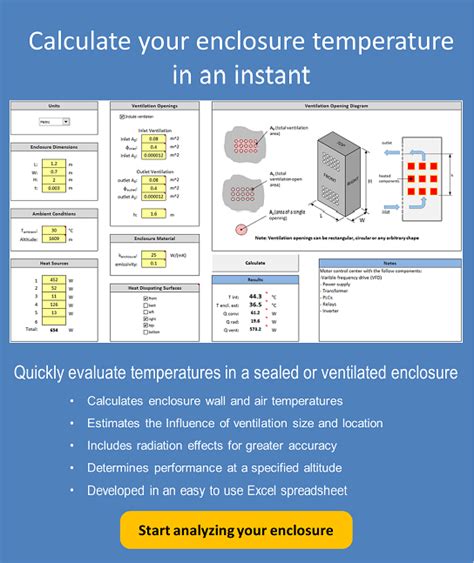

1 · vented enclosure temperature rise

2 · polycase enclosure ventilation

3 · instrument enclosure venting

4 · instrument enclosure vent plugs

5 · how to vent an enclosure

6 · how to find vented enclosure

7 · electrical vent enclosures

I had water running into a broken service head above a meter. Then thru the meter it's self. Then entering the customers neutral at the connection in the middle of the meter, traveling 160 feet underground inside the neutral and dripping inside his service panel in the basement.

If the device components inside your electronics enclosure generate any significant amount of heat, it’s likely that your enclosure will need some kind of ventilation. Large devices that generate high levels of heat will usually require an engineered mechanical ventilation solution designed specifically for that . See more

sheet metal workers local 20

There are two major categories of enclosure ventilation: passive and forced air. 1. Passive ventilation uses non-mechanical design elements, such as ventilation holes cut . See morePolycase is a leader in industrial and commercial electronic device enclosures. Although Polycase’s enclosures don’t come with built-in . See more Using the latest CAD/CAM automation technology, we can produce CNC machine cutouts of nearly any size or shape to any surface with extreme accuracy. With precision cutting, we can create a custom venting .

well ventilated instrument enclosure

Put the ENCLOSURE EXHAUST [A] on the top of the machine enclosure. Install the (4) WASHER [D] and the (4) NUT [E] to the standoffs for the ENCLOSURE EXHAUST [A]. For .Start loading parts sooner, without waiting for the coolant mist to clear from the machine enclosure. The Haas Enclosure Exhaust System keeps the machine’s interior clear of mist and smoke generated during the machining process, .

Hennig CNC machine tool enclosures and roof bellows have everything you need, including ventilation systems, automated doors, soundproofing, and more features that maximize safety and productivity in your facility.To achieve this I decided to line the walls and the back of the enclosure with noise dampening poly-urethane foam sandwiched between two sheets of 6mm mdf. I used about 60mm of foam in the wall cavities and held the layers . Your enclosure looks great. I do not see a cyclone separator where your shop vac is. The cyclone separator will keep your vacuum from getting clogged quickly. Onieda sells the dust deputy and there are plans for a Thien .Shop a variety of venting accessories for NEMA enclosures from Polycase. Buy large air vents, NEMA rated vents and more enclosure accessories at polycase.com.

vented enclosure temperature rise

polycase enclosure ventilation

Use this short guide to ventilated enclosures to get familiar with all the key basics of enclosure ventilation–from calculating your enclosure’s heat levels to the different types of ventilation available.

Using the latest CAD/CAM automation technology, we can produce CNC machine cutouts of nearly any size or shape to any surface with extreme accuracy. With precision cutting, we can create a custom venting solution built to your CAD specifications.

Put the ENCLOSURE EXHAUST [A] on the top of the machine enclosure. Install the (4) WASHER [D] and the (4) NUT [E] to the standoffs for the ENCLOSURE EXHAUST [A]. For lathe models ST-40 and larger [3], install the (4) WASHERS [D] and the (4) NUTS [E] between the two layers of sheet metal.

Start loading parts sooner, without waiting for the coolant mist to clear from the machine enclosure. The Haas Enclosure Exhaust System keeps the machine’s interior clear of mist and smoke generated during the machining process, improving visibility and allowing for faster workpiece exchange.Hennig CNC machine tool enclosures and roof bellows have everything you need, including ventilation systems, automated doors, soundproofing, and more features that maximize safety and productivity in your facility.To achieve this I decided to line the walls and the back of the enclosure with noise dampening poly-urethane foam sandwiched between two sheets of 6mm mdf. I used about 60mm of foam in the wall cavities and held the layers together with spray on contact adhesive. Your enclosure looks great. I do not see a cyclone separator where your shop vac is. The cyclone separator will keep your vacuum from getting clogged quickly. Onieda sells the dust deputy and there are plans for a Thien type that you can make on your cnc. Take a look at this: https://woodgears.ca/dust_collector/separator.html

Shop a variety of venting accessories for NEMA enclosures from Polycase. Buy large air vents, NEMA rated vents and more enclosure accessories at polycase.com. there are many great videos about enclosures for CNC machines. Some work incredibly well in reducing noise. Those all have in common to be huge, heavy and take a lot of work to build. Which makes it difficult to remove when working on .

CNC Enclosure and Vent. I've been designing and printing 3D parts for several years. However, at the beginning of the pandemic, I purchased a desktop CNC machine and quickly decided that I should build an enclosure, and negative pressure system to help keep the dust under control. Use this short guide to ventilated enclosures to get familiar with all the key basics of enclosure ventilation–from calculating your enclosure’s heat levels to the different types of ventilation available.

Using the latest CAD/CAM automation technology, we can produce CNC machine cutouts of nearly any size or shape to any surface with extreme accuracy. With precision cutting, we can create a custom venting solution built to your CAD specifications. Put the ENCLOSURE EXHAUST [A] on the top of the machine enclosure. Install the (4) WASHER [D] and the (4) NUT [E] to the standoffs for the ENCLOSURE EXHAUST [A]. For lathe models ST-40 and larger [3], install the (4) WASHERS [D] and the (4) NUTS [E] between the two layers of sheet metal.Start loading parts sooner, without waiting for the coolant mist to clear from the machine enclosure. The Haas Enclosure Exhaust System keeps the machine’s interior clear of mist and smoke generated during the machining process, improving visibility and allowing for faster workpiece exchange.

Hennig CNC machine tool enclosures and roof bellows have everything you need, including ventilation systems, automated doors, soundproofing, and more features that maximize safety and productivity in your facility.

instrument enclosure venting

To achieve this I decided to line the walls and the back of the enclosure with noise dampening poly-urethane foam sandwiched between two sheets of 6mm mdf. I used about 60mm of foam in the wall cavities and held the layers together with spray on contact adhesive. Your enclosure looks great. I do not see a cyclone separator where your shop vac is. The cyclone separator will keep your vacuum from getting clogged quickly. Onieda sells the dust deputy and there are plans for a Thien type that you can make on your cnc. Take a look at this: https://woodgears.ca/dust_collector/separator.htmlShop a variety of venting accessories for NEMA enclosures from Polycase. Buy large air vents, NEMA rated vents and more enclosure accessories at polycase.com. there are many great videos about enclosures for CNC machines. Some work incredibly well in reducing noise. Those all have in common to be huge, heavy and take a lot of work to build. Which makes it difficult to remove when working on .

instrument enclosure vent plugs

Weatherproof electrical boxes withstand rain, snow, moisture, and outdoor elements. Electricians and contractors use these boxes to protect wiring and electrical devices in outdoor installations.

cnc machine enclosure venting|instrument enclosure vent plugs