cnc machine violin In part 10 I will be cutting the top plate of the Guarnieri 'del Gesu' Vieutemps violin from 1741. I will discus the process I go through to refine the tooli. A steel frame for a 1,500-square-foot house can cost between $14,250 and $16,500 in materials alone. Materials for a wooden frame of the same size would cost between $1,500 and $7,500. But if you’re looking into building a barn or a similar outdoor structure, steel would likely be a cheaper option.

0 · wooden violin cnc machine

1 · how to cnc a violin

2 · dutch violin cnc machine

3 · cnc file violin

$8.49

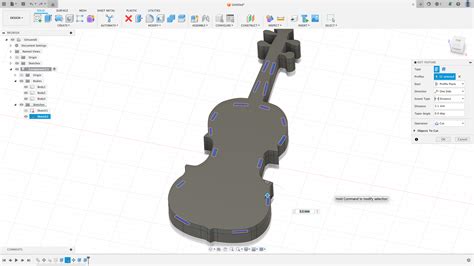

In part 10 I will be cutting the top plate of the Guarnieri 'del Gesu' Vieutemps violin from 1741. I will discus the process I go through to refine the tooli.See how Frank van der Horst used CAD and CNC to improve the classic violin design, using the DeskProto 3D CAM software. This video shows the process of building a violin out of olive wood and spring green-colored epoxy resin using the Shapeoko XXL CNC router and other modern as well as traditional wood working. Part 16 of making the Guarnieri "Vieuxtemps" violin. CNC cutting the Neck and scroll. https://www.patreon.com/Twocherriesinstrumentshttps://www.twocherriesin.

You have a couple of options - build your own CNC system or send your files to a fabrication service. the former is expensive unless you are doing vast quantities. As for the . CNC Carving a Violin. Artist Dennis Van Hoof shows off his violin-making process which combines modern tech with traditional woodworking. He uses a Shapeoko XXL CNC router to carve the instrument’s pieces from olive .

CNC Violin. By TheTester_280 in Workshop CNC. 268. Save PDF. Hello my name is Jonathan and I attend Sage Oak Charter School. I will be showing you how to Model and CNC a Violin.CNC Carving Violin Plates: Now that the ribs are bent and glued into the form along with the top side of the linings it's time to cut the top and bottom plates. I preformed a lot of test cuts in order to find a process that would give me the .

wooden violin cnc machine

I have access to a CNC machine. It uses VCarve as the software to import the .stl files. From there it generates the G code. I am thinking about going down the dark path of . Final versions for sale through my website:https://topoarts.com/violins-out-of-olive-wood/By Dennis Van Hoof, from Top o' Arts (topoarts.com).This video show. In this video, I interview Violinmaker John Kirk, who crafts violins using a CNC machine. John shares his insights on how much of the violin-making process c.

If you are planning on mass producing a violin, you don't need a CNC machine. You can build your self a duplicarver and simply copy a generic top shape by buying a good quality violin. One man with a duplicarver can probably copy a top in about 30 min, inside and out. Maybe if he was doing it all day, even 15 min.

I would like to correspond with anyone who is doing violin construction using CNC. Thanks for your reply. Similar Threads: tried the violin blank again with 1/2 bit; Need Help!- . Right now I just do metal CNC. I'm working on a new woodworking machine. Dick. 07-05-2007, 03:19 PM #3. plumbseed. View Profile View Forum Posts Private Message . hello.I'm living in Iran and here is limited, if you scan a file for violin cnc machine for my email. Thank you. my emil [email protected] ariana wrote at 8/18/2013 2:17:45 PM: Even Stradivari did something different each time, and he learned from that. I think it's safe to say that no CNC violin maker will start with anywhere near Stradivari's knowledge, and yet will be relatively locked into a single form virtually immediately. . Now his company has professional managers and makes (with CNC machines) and sells . Gorilla CNC Machines; K2CNC; Larken; Multicam Machines; Omni CNC; Roctech CNC Routers; Shopsabre; Stepcraft; Techno CNC; XYZ Gantry Routers; DIY CNC Router Table Machines. FAQ of DIY CNC Machine Building; Avid CNC; CNC Wood Router Project Log; FineLine Automation; Joes CNC Model 2006; Momus Design CNC plans; Open Source CNC .

How common a practice is machine carving (duplicator or CNC) of violin plates among individual makers? Are there any ethical issues involved? What do folks think of the practice? I thought it might be informative to show the precision of CNC machining of mandolin tops. By programming curtate cycloid curves in 0.125 increments very little roughing is required to achieve a perfect curved surface. There are several benefits to using the CNC; exact replication from part to part, precise curvature generation and best of all, can be run at night, . My granddaughter told me she took violin lessons in school, so great, that was going to be my next project. I used Aspire and Rhino 8 for modeling. I was planni . Model of CNC Machine: Legacy Artisan 72 and AVID CNC Rotary Location: Royal City Washington. Re: Violin. Post by dhellew2 » Sun May 19, 2024 11:18 pm. Looks great. Dale

One case of CNC imitating traditional craftsmanship was a 2012 project undertaken by a radiologist and two violin-makers, who set out to recreate a 1704 Stradivarius violin — one of the most expensive instruments on the planet. With the use of a CT scanner and CNC machine, they were able to remake the form and precise structure of the iconic . I am a CNC programmer and I program CNC milling machines. I just started playing the violin but I would like to start making them on the CNC mill. Are there any makers that use this method? I could create 3D computer cad models of all the parts and produce them precisely on a CNC milling machine. I would leave just enough material for finishing . In addition, if the CNC machine does not have an automatic tool changer (and most don’t), you will be highly limited regarding what you can actually accomplish as the accuracy required in a violin plate or scroll makes it difficult to “re-zero” accurately enough in a .

Thinner top and bottom- another poster points this out, but I have read that studies of the best sounding violins revealed that by and large the thinner these are, the better the sound. How thin you could get with a cnc machine is anyone's guess though. This thing would probably make a very excellent electric violin.

Model of CNC Machine: MechMate Location: South Africa. Rotary maching Violin neck in V9.5. Post by woody1 » Fri Nov 30, 2018 8:08 am. Hi there, . I have been trying to carve a violin neck on my rotary axis for years using V4.5. Only way I get it right is to do the one side, flip it 180 degrees and do the other side. .

It is NOT machine-made, and this is a stupid prejudice. The machine roughs out parts, that is all. there is a LOT of hand-work at the edges and the CNC-cut surface. I can see that you have not used a CNC for anything. Besides, one cannot tell how things are roughed out. And if "machine-made" is a valid notion, what is wrong with it. Operator Skill: Skilled operators are essential for programming, setting up, and effectively operating 5-axis machines. Cost: The initial investment in 5-axis machines and tooling is typically higher than that for traditional CNC . After the CNC machine completed carving the "Betts" violin's replica, Waddle and Rossow finished, assembled and varnished the new violin by hand. Shown above is the final version of the .

This was my first test path for bridge blanks back in 2012 and how I make my bridges for my violins. My custom blanks are modeled in CAD based on my hand cut.Howery Violins: Probotix CNC Machine for SaleFeaturing: Probotix Asteroid 37” X 25” working bed Big enough for cello plates Violin/Viola G-code mod.

how to cnc a violin

Storey milled the violin body using a 3-axis CNC machine, to prove that . Basl. é could use a simple desktop CNC machine for milling wood in his workshop. Combining a powerful generative design tool, a desktop router, and an expert luthier is a completely novel way to manufacture an electric violin. This workflow bridges the gap between the .

Part 16 of making the Guarnieri "Vieuxtemps" violin. CNC cutting the Neck and scroll. https://www.patreon.com/Twocherriesinstrumentshttps://www.twocherriesin. CNC machines Edited: October 8, 2020, 5:12 AM In this blog post, we delve into the world of CNC violin making machines and explore their impact on the industry. 1. The Rise of CNC Technology in Violin Making\ 1.1 The Role of CNC Machines in Precision and Accuracy\ 1.2 Enhanced Productivity and Efficiency in Violin Production\ 1.3 Sustainable Practices and Reduced Waste . 2.

It is way more easier to program LOL, but sorry to break your heart again! the pattern you see was a eBay pre-carved violin back that also came with a top and sure looks most likely made by CNC, it was to perfect to be hand done but also I could tell it was not steam pressed to shape be cause the grain in the wood was straight, but the quality of the wood itself . Second, some people suggest that if a CNC router is used, the "machine" is building the violin (a "machine-made" violin). Those people apparently do not know how a CNC router works. There is a huge amount of human work that goes into the process, and arguably more difficult work, with more demanding skills required.

I build just mandolins, I do just repairs on violin family. I used to use some CNC work years ago, like body blocks cut on CNC, designed and cut new body form on CNC and some other tasks but as I wrote earlier, the closer I am to finishing my own CNC (it still may take few years with my limited free time) the more handwork I'm using, the latest two mandolins being .

high precision machined parts suppliers

dutch violin cnc machine

Durable and Long-Lasting: Bread boxes are typically made from durable materials, such as wood or metal, which ensures longevity and resistance to wear and tear. Larger Footprint: Bread boxes can take up more space in your kitchen than bread bags. This may be a concern for those with limited storage space.

cnc machine violin|how to cnc a violin