manufacturing processes sheet metal forming What Is Sheet Metal Forming? Sheet metal forming entails taking thin, flat sheets of metal and manipulating them into fully formed 3D structures. The process transforms a basic raw material into complex finished products . Before installing the junction box, determine the best location where it can be mounted. The box can be mounted anywhere inside the room — on the ceiling or on the walls. When the location has been set, run the wires to meet .

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal forming process pdf

4 · sheet metal forming press dies

5 · sheet metal forming by hand

6 · sheet metal bending process pdf

7 · bulk deformation vs sheet metal forming

Trust the industry's largest provider of end-to-end wire and cable management for indoor and outdoor applications. Explore Wiremold floor boxes, poke-thru devices, cable raceways and more.

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different . What Is Sheet Metal Forming? Sheet metal forming entails taking thin, flat sheets of metal and manipulating them into fully formed 3D structures. The process transforms a basic raw material into complex finished products .

Sheet metal forming, a versatile manufacturing process that transforms flat metal sheets into complex and intricate shapes, is a crucial aspect of modern engineering. This article, written by experts in the field of sheet .

cnc machining camera components

After cutting, sheet metal components often undergo forming processes, such as bending and stamping, to shape them into three-dimensional configurations. Bending involves applying force to the sheet along specific lines, creating .In this blog, we dive into seven key sheet metal forming processes that shape modern manufacturing: Laser Cutting, Water Jet Cutting, Stamping, Welding, Roll Forming, Spinning, and Rolling. In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, . Sheet metalworking, also known as Sheet metal forming and sheet metal fabrication, is a manufacturing process of cutting and forming relatively thin metal sheets, strips, and coils to create desired shape sheet .

Sheet metal forming is a highly versatile and widely used manufacturing process that involves shaping metal sheets into the desired parts and products. This intricate process plays a crucial role in various industries, .

sheet metal working process pdf

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.Sheet metal forming is used for industrial manufacturing in many sectors – from car door to tin can. In sheet metal forming, the final shape of a part is made from a flat metal sheet. The desired shape is achieved through plastic deformation, .

In this manuscript, we present a comprehensive overview of true digital twin applications within the manufacturing industry, specifically delving into advancements in sheet metal forming. A true digital twin is a virtual representation of a physical process or production system, enabling bidirectional data exchange between the physical and digital domains and .•Hydro-forming – cheap tooling, no net thinning, slow, high formability Material stretched into shape •Stretch forming – very cheap tooling, net thinning, slow, low formability •Super-plastic forming – cheap tooling, net thinning, expensive sheet metal, slow, very high formability Technology – a brief review Forming Speed 20 .

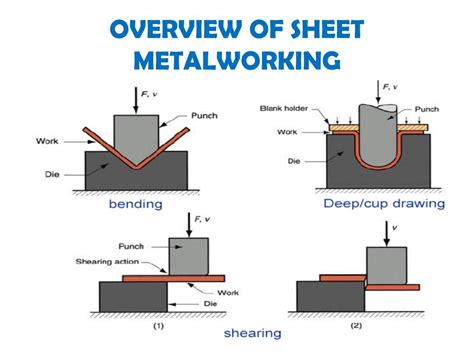

7. Shearing Operations The most common shearing operations are punching-where the sheared slug is scrap or may be used for some other purpose-and blanking-where the slug is the part to be used and the rest is .

Sheet Metal Forming Processes. There are a variety of core manufacturing processes used to form sheet metal into parts. The techniques deployed depend on the geometries and production volumes needed, as well as the formability of the selected metal. . Sheet metal laser cutting is a manufacturing process to cut sheet metal materials using a .Sheet metal stamping is a cold-forming process using presses and dies to shape materials. It works with various metals, including stainless steel, carbon steel, aluminum, brass, and copper. Stamping combines cutting and forming techniques like bending, punching, embossing, and flanging to produce complex components quickly.

1. Metal forming processes Metal forming: Large set of manufacturing processes in which the material is deformed plastically to take the shape of the die geometry. The tools used for such deformation are called die, punch etc. depending on the type of process. Plastic deformation: Stresses beyond yield strength of the workpiece material is required.

This chapter provides an introduction to metal forming processes and where they fit among the five general areas of manufacturing. It also discusses the basic differences between bulk deformation and sheet-metal forming processes and how they relate to hybrid forming processes such as drawing, bending, and coining. Some metal manufacturing processes, such as extrusion and machining, use metal bars or billets as the raw material feedstock. Others like stamping and coining use sheet metal. Processes that use metal powders as feedstock, meanwhile, can be grouped under the general category of powder metallurgy. BENDING Bending of sheet metal is a common and vital process in manufacturing industry. Sheet metal bending is the plastic deformation of the work over an axis, creating a change in the part's geometry. Similar to other metal forming processes, bending changes the shape of the work piece, while the volume of material will remain the same.

Research and development in sheet metal shaping requires knowledge within several disciplines, including materials, tribology and processing, as well as knowledge of the equipment for testing and verification. Swerim has depth knowledge in the field and good access to lab equipment. Process, methods and materials for sheet metal formingSheet Metal Bending & Forming Services. Whether you need simple bends, complex geometries, or custom shapes, our experienced team is well-equipped to handle any project, big or small. . Sheet metal bending is a manufacturing process in which a flat sheet of metal is formed into a desired shape by applying force to bend it along a straight axis.

cnc machining bit specialty

Explanation: Sheet metal forming is a process which uses ductile materials like aluminium or low carbon steel to form lightweight products with versatile features. Car bodies are mainly manufactured by sheet metal forming by performing operations like shearing, slitting, cutting, or sawing of thin metal plates.Sheet metal manufacturing processes encompass a range of techniques aimed at shaping and forming metal sheets into desired products. In this article, we will explore some of the key processes involved in sheet metal manufacturing. 1. Cutting: The first step in sheet metal manufacturing is cutting the raw material into the desired shape and size.The raw material for sheet metal manufacturing processes is the output of the rolling process. Typically, sheets of metal are sold as flat, rectangular sheets of standard size. If the . • Bending: forming process causes the sheet metal to undergo the desired shape change by bending without failure. Ref fig.12. Deformation . Sheet metal deforming processes involve changing and processing sheet metal without cutting it. Bending is one of the most critical forming processes, and it can be done using a brake machine.A sheet metal .

Typical Sheet Metal Working: Drawing Operation: (a) It is a forming process by pushing a punch against a flat sheet and forcing it into a die to take the required shape. Or in other words drawing is the operation of producing thin walled, hollow shaped parts from sheet metal. Both the die and the punch have shape of the part to be manufactured . Consistency and Reproducibility: Metal forming processes are highly controllable, which ensures consistent quality and repeatability in mass production settings. Disadvantages of Metal Forming. High Initial Costs: The tooling and setup required for many metal forming processes, such as stamping and extrusion, can be costly. These initial .

sheet metal stamping process pdf

sheet metal processes pdf

Instead of manufacturing the entire part directly with PBF-LB/M, in [81] the additive process is used to produce a tailored blank, which is then formed in a sheet-bulk metal forming process to produce a cup with tooth-shaped functional elements on the outside of the wall. For this purpose, the sheet thickness is locally increased by PBF-LB/M .Of these manufacturing processes, forming is a widely used process that finds applications in automotive, aerospace, defense and other industries. . They are bulk forming processes and sheet metal forming processes. Each category includes several major classes of . In short, roll forming involves continually feeding a long strip of metal through drum rollers to attain the desired cross-section. This process is highly efficient and cost-effective, making it the preferred choice for producing long lengths of sheet metal with consistent profiles.of metal forming processes, as a component of the virtual manufacturing process, has a very important contribution to the reduction of the lead time. The finite element method is currently the most widely used numerical procedure for sim-ulating sheet metal forming processes. The accuracy of the simulation programs

cnc machining british columbia

Sheet metal forming is highly prevalent in manufacturing. Sheet metal parts can be discovered in a broad spectrum of applications, such as in the automotive sector, aerospace field, consumer goods, and household appliances. . Hydroforming is a specialized sheet metal forming process that utilizes high-pressure hydraulic fluid to shape the . Incremental sheet metal forming (ISMF) has demonstrated its great potential to form complex three-dimensional parts without using component-specific tools against the conventional stamping operation.In the field of bulk forming, it examines processes of cold, warm and hot bulk forming, as well as rolling and a new addition, the process of thixoforming. As for the field of sheet metal working, on the one hand it deals with sheet metal forming processes (deep drawing, flange forming, stretch drawing, metal spinning and bending).

Principles of Incremental Sheet Forming Incremental Sheet Forming is a versatile manufacturing process that involves the gradual deformation of a metal sheet using a localized tool. Unlike traditional forming processes that utilize dies and molds, ISF employs a CNC-controlled tool that moves incrementally, shaping the metal sheet layer by layer. Sheet metal forming is a manufacturing process where three dimensional parts are created by flat sheet. There are two process associated with sheet metal forming stamped and forming which are used in aerospace, automobile industries [43]. Stamped product can be curved and bend at one time whereas formed product consist of straight bends. In simple terms, The hydroforming (or fluid-forming) process is a manufacturing process that uses water pressure to shape flat sheets of metal into three-dimensional parts. This unique approach opens up a whole new world of possibilities for engineers and manufacturers to create complex shapes with ease.

sheet metal forming process pdf

$49.95

manufacturing processes sheet metal forming|sheet metal forming press dies