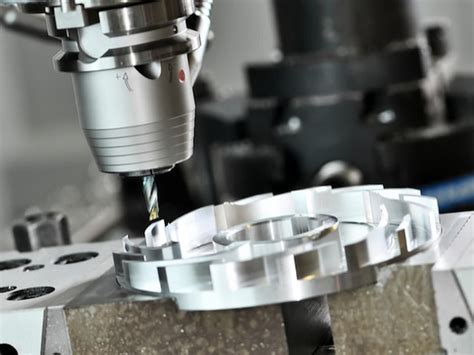

why cnc machine is important Why is CNC machining necessary? CNC Machining has provided an important breakthrough for precision machining. It was developed in the late 1970s by American inventor H. David Dodson. CNC machines are like a computerized machine tool, which is used to cut metal or plastic components with high precision and accuracy. The importance of CNC machining can be seen . We offer a complete stainless steel CNC machining service and can produce complex stainless steel parts with 11 different types of stainless steel. Stainless steel parts are great for applications that require high strength, corrosion resistance, heat .

0 · what can cnc machines make

1 · understanding cnc machines

2 · how to cnc machining work

3 · how does cnc machining work

4 · how cnc machine is controlled

5 · computer numerical control cnc machines

6 · cnc machine used for

7 · cnc machine capabilities

Source over 17411 cnc machined parts for sale from manufacturers with factory direct prices, high quality & fast shipping.

By replacing manual processes with computer numerical control, it offers precision, consistency, and efficiency that traditional methods can’t match. This article will explore the main benefits of CNC machining and why it might . Why is CNC Important in Modern Manufacturing? 1. Precision and Accuracy Tolerances and Repeatability. CNC machines achieve high precision and accuracy. . Why a CNC Machine is Important in the Design of Compressor Parts. The CNC machine has made it essential in the design of compressor parts. Here’s why it is so important: 1. Variety of Designs. CNC machines can be used to create materials in a wide variety of shapes and sizes. They are also controlled by a program that enables them to carry .

CNC machines are precision turning machines that operate autonomously. No manual intervention is required, which bypasses the possibility of human errors. Software programs and codes govern the end-to-end CNC .

Why is CNC machining necessary? CNC Machining has provided an important breakthrough for precision machining. It was developed in the late 1970s by American inventor H. David Dodson. CNC machines are like a computerized machine tool, which is used to cut metal or plastic components with high precision and accuracy. The importance of CNC machining can be seen .Using CNC machines are much safer than manually operated machines as they work behind a guard or even a closed, transparent safety door. CNC machining is more cost-effective. Traditional machining requires one operator per machine. This type of machining requires fewer machine operators since one skilled operator can run several machines at one . Accuracy is the most important aspect in CNC as well as manual machining since it is the basis for the quality, fit, and function of manufactured parts. . Machine Operations: Why CNC Machines Require Less Manual Intervention. Automation and sophisticated programming capabilities make it feasible for CNC (Computer Numerical Control) machines .

The production capacity of aerospace manufacturing industry can reflect the national defense technology and economic strength of a country. While the demand for CNC technology and equipment in aerospace manufacturing is very clear and urgent. The quantity, performance, accuracy, processing ability and application level of CNC machine tools are of great . Why Outsourcing Preventative Maintenance Services Makes Sense. Regularly performing vital tasks such as cleaning the machine daily, replacing essential parts before they fail, and responsible operations can extend the life and durability of CNC machines. Some routine maintenance activities can be completed in-house by trained CNC machine operators. Let’s look at each of these reasons why the machining industry is so important in more detail, and understand the benefits each of them provides. Versatility of CNC Machining. . CNC machines are computer-controlled, meaning that there is no need for an operator to be present when the machine is running and no longer any need for workers to . CNC machining has revolutionised manufacturing with its numerous CNC machine advantages when compared to conventional machining. By replacing manual processes with computer numerical control, it offers precision, consistency, and efficiency that traditional methods can’t match. . It’s important to understand these disadvantages to decide .

Why Do We Need CNC Machine Maintenance? . For important assets, predictive maintenance is preferable over preventive maintenance. Proper use of is necessary to achieve the maximum benefit of predictive maintenance. With condition-based CNC machine monitoring, technicians monitor machine performance to predict which parts need servicing before .

what can cnc machines make

That’s why we invest in state-of-the-art CNC milling machines and employ industry-leading experts to ensure the best possible outcomes for our customers. When you choose Elemet, you’re choosing a partner that values your satisfaction and is .CNC machines are capable of producing parts that are accurate up to within a few thousandths of an inch, making them ideal for applications where precision is critical. Why is Precision CNC Machining Important? Precision CNC machining is crucial for a variety of reasons. Firstly, it ensures that the final product meets all the required .

cnc horizontal boring milling machine

Why Outsourcing Preventative Maintenance Services Makes Sense. Regularly performing vital tasks such as cleaning the machine daily, replacing essential parts before they fail, and responsible operations can extend the life and durability of CNC machines. Some routine maintenance activities can be completed in-house by trained CNC machine operators.Why Outsourcing Preventative Maintenance Services Makes Sense. Regularly performing vital tasks such as cleaning the machine daily, replacing essential parts before they fail, and responsible operations can extend the life and durability of CNC machines. Some routine maintenance activities can be completed in-house by trained CNC machine operators. If we want our corners sharp and pristine, our tools will have to follow this 180-degree path, and CNC machines do not have the tools to do the same. You will have to stop your machine to move the pieces. . the radius plays an important role in CNC machining. By reasonable selection and control of tool radius, machining accuracy, efficiency .

When discussing CNC machining, we often refer to terms such as accuracy, tolerance, and precision.What do these mean and why are they so important to the precision CNC machining process? Our next series of articles will further .The Importance of CNC Machine in Manufacturing. CNC machining has transformed the manufacturing world without a doubt, and the effects of that can be seen on a daily basis. Manufacturing has become faster, goods have .This is why CNC machine preventive maintenance is such a vital part of your overall business plan. Keeping your tools and machines working in tip-top condition keeps your company profitable for the long run. Let’s explore how. Minimize Costly Breakdowns. CNC machine breakdowns can cost as much as five times the cost of preventive maintenance.

understanding cnc machines

Why Precision Machining Is Important to a CNC Machine Shop CNC cutting machines, like routers and mills, create products by making cuts into the desired workpiece across several axes. These machines at Bates MAchine and Mfg. in Farmersville,Texas work off of computer design programs to create uniform, accurate products. CNC machines also allow for the fabrication of complex-geometry parts because of their operation across 3 and 5-axes. Types of CNC machines. There are different types CNC machines. Below is a brief on the most common types of CNC machines that are used in everyday manufacturing: CNC Lathing

CNC operators can take raw materials and turn them into finished pieces with precision. The Importance of CNC Machining in Manufacturing. CNC machining is now found in many different industries. As an aid in manufacturing, it has some significant benefits. 1. More Accuracy. One of the most important aspects of manufacturing is accuracy.Workholding and setup is important! The thing with machining is that it can often be the reverse of 3d printing. Whereas 3d printing costs more to add material, machining costs more to remove material. Literally the cheapest you can do in the machining world is a solid chunk cut off with a bandsaw or something. . CNC machines can cost .

A CNC router will probably be the best option if wood is your main material. A CNC plasma cutter is the finest choice if you aim to work on metals. Cost: Bear the price in mind. Cost includes both labor and maintenance costs in addition to the machine’s price. Machine Weight: Take into account the machine's weight. Cast iron construction is .

Why is CNC Machining Important? CNC machining is a process that uses computer numerical control (CNC) machines to shape and cut materials into desired shapes and sizes. It is a highly precise and automated process that is used in a variety of industries, from aerospace to automotive. CNC machining is important because it allows for the . CNC BARON MILLING MACHINE; Jr. CNC Benchtop Milling Machine; Lathe 1440 CNC Machine Turning Center Catalog; CNC Milling Machines. Table Top Milling Machines At CNC Masters, we offer a range of outstanding table top milling machines. Each of these compact CNC mills is designed to pack maximum power into a small footprint, all while remaining .

Why Outsourcing Preventative Maintenance Services Makes Sense. Regularly performing vital tasks such as cleaning the machine daily, replacing essential parts before they fail, and responsible operations can extend the life and durability of CNC machines. Some routine maintenance activities can be completed in-house by trained CNC machine operators. Additionally, we need to understand what CNC machines are and why CNC technology is so important to understand why this kind of equipment is so beneficial. Definition and Working Principle CNC machining is a manufacturing process in .

how to cnc machining work

cnc heavy machining s.r.o

cnc horizontal cutting machine factories

eMachineShop offers CNC machining, sheet metal fabrication, 3D printing, injection molding and various finishing options. Simply upload your design, enter your specifications and get a reliable manufacturing quote. Precision milling .

why cnc machine is important|how cnc machine is controlled