expertise in metal fabrication processes machining castings welding edm etc Aero Manufacturing Corporation specializes in the fabrication and machining of . If you have the stem mount junction A, stick the mount on the underside of the stem and then fit the box to it - much neater than the fugly strap. I personally use black Sugru which is.

0 · Electrical Discharge Machining: Process, Types, and Application

1 · Electrical Discharge Machining (EDM)

Start NX 11 and create a new Sheet Metal model called casing.prt. Exit the sketch mode. 2 – Changing design parameters. Go to MenuÆPreferencesÆSheet Metal. 3 – Adding a solid sheet and cutout. Use the Tab button for creating a first rectangular metal sheet of 1 mm in thickness.

EDM processes present several advantages for custom metal fabrication. When details and precision matter, the EDM provides very precise cuts with tolerances as low as +/- .0005. .With nearly 50 years of experience, Aero Manufacutring offers welding, EDM, .Machining (EDM) CNC Machining; Metal Working; Laser Services; . We meet .We work with a wide range of manufacturing materials including Alloy .

Aero Manufacturing Corporation specializes in the fabrication and machining of .Starting as a small machine shop in Beverly, Massachusetts in 1971, Aero .

We utilize over 150 machine tools for Laser Services, Metal Working, CNC .Welding Services; Electrical Discharge Machining (EDM) CNC Machining; Metal .With machining experience since 1971, Aero Manufacturing Corp continues to .

Aero Manufacturing Corporation 100 Sam Fonzo Drive Beverly, MA 01915. Main: .Whether your components are big or small, our state-of-the-art facility utilizes cutting .

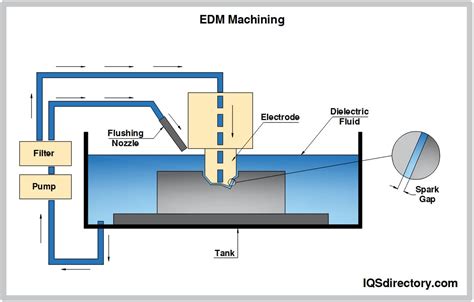

The process operates through electrical discharges between an electrode and workpiece, both submerged in a dielectric fluid. Within a discharge gap of 0.01-0.5mm, thousands of sparks per . Machining Capabilities: Look at what types of processes are provided, for example, milling, turning, grinding, electrical discharge machining (EDM), etc). Besides having multi-axis capabilities like 3-axis, 4-axis, 5 axis machines for increased versatility and complexity in part production.international team of expert contributors, Metalworking fluids (MWFs) for cutting and grinding is an invaluable reference tool for engineers and organizations using metal cutting/machining in the manufacturing process as well as machine designers/manufacturers and machining fluid/chemical suppliers.

The manufacturing processes course did require the use of calipers, micrometers, knowing all names and functions of measuring and fabricating equipment in the shop, and the operation of milling machines, lathes, CNC machines, plasma tables, bandsaws, bench grinders, etc. for projects in the course, in addition to regular lectures on a pretty .Die-casting is a versatile process to produce metal parts by forcing molten metal under pressure into steel molds or dies with a high degree of accuracy and repeatability. Boyd’s decade of experience in high-pressure aluminum die casting enables us to produce aluminum die castings with tight tolerances, reducing the amount of finishing .Electrical Discharge Machining (EDM) is a non-traditional metal fabrication process. It uses a series of rapid, controlled electrical sparks to remove material from a workpiece. This subtractive manufacturing method converts electrical energy into thermal energy, melting excess material to create precise cuts and shapes.

To make vehicles, metal fabricators put metals through different processes, including machining, cutting, forming, and even welding. All these processes ensure that the metal parts used in a . Sheet metal fabrication is a fundamental process in the manufacturing industry that involves shaping and manipulating sheet metals into desired forms. It plays a crucial role in various sectors, such as automotive, aerospace, construction, and electronics.The applications of sheet metal fabrication are vast, ranging from creating intricate components for machinery to . Surface texture evaluation of machined components using Vision System Engineering surfaces originated by a diverse manufacturing processes like casting, forging, and secondary processes like turning, milling, etc. Technological advances in the area of manufacturing have resulted in closer tolerances on the parts being produced by all these . We produce metal parts, components, and assemblies involving single or combinative processes such as machining, metal fabrication, casting, forging, etc. Our products are applied to a variety of industries serving a wide range of purposes, such as Machinery, Rail Transit, Power/Energy, Boat/Bridge, Infrastructure, Oil/gas, Aerospace, etc .

However, every metal casting component goes through multiple complex manufacturing processes. Each process plays a crucial role in the overall casting quality. Indeed, good quality castings are reliable and ensure effective performance in machinery. Inspection of casting is a method of testing metal parts.

There are four chief manufacturing processes i.e. (1) welding, (2) casting, (3) machining and (4) forming. Selection of suitable manufacturing process for a product/component is determined by the following factors: i. Complexity of geometry of the .Metal fabrication techniques are vital in industries like manufacturing, construction, etc. There are various techniques like forging, casting, machining, etc. Such fabrication techniques allow the creation of custom parts and components essential for successful projects.

To date, we have accumulated rich experience in CNC machining, sheet metal fabrication, welding, metal cutting, die casting, heat treatment, surface treatment, and plastic products. We are willing to provide products and services with good quality, favorable prices and timely delivery to major customers in the industry.Precision sheet metal fabrication is a common manufacturing process where the structure of a metal workpiece is cut, bent, and assembled by machining. There are any number of operations that are performed in the creation of a finished sheet metal product. CNC machines: CNC machining involves computer-controlled tools that offer very accurate cuts during drilling, milling, etc., making them suitable for producing precision sheet metal parts where dimensions must remain constant throughout the production process; hence, mills or lathes may be preferred over other methods when intricate components .

Electrical Discharge Machining: Process, Types, and Application

However, we focused on discussing the major ones, especially concerning metal fabrication. Other CNC machining services include: Wire EDM; Grinding; Challenges and Solutions in CNC Machining for Metal Fabrication. .EDM processes present several advantages for custom metal fabrication. When details and precision matter, the EDM provides very precise cuts with tolerances as low as +/- .0005. Additionally, complex shapes and configurations and very . Openex is one of the very few companies that have the capabilities to provide a full range of metalworking products and services to customers worldwide. We produce metal parts, components, and assemblies involving single or combinative processes such as machining, metal fabrication, casting, forging, etc. Our products are applied to a variety of industries .

To metal fabrication manufacturers, the understanding of metal types, looks, characteristics, machinability and properties are essential. Let’s define the metal material into different categories and explore the characteristics and usages of different materials, to know what process is required for the certain material or what material you should choose for your .

What is EDM (Electric discharge machining)? EDM is a non-traditional machining process that uses electrical sparks to erode material from a conductive workpiece. In EDM, a rapidly pulsing current is passed between an electrode tool and the workpiece submerged in a dielectric fluid, creating a spark discharge gap.In Bole Precision CNC Machining Shop, we can process large-dimension parts on a large production scale. . Sheet metal fabrication center guide. Professional engineers handle CNC punching, laser cutting, bending, metal stamping, welding and assembly . metal stamping, welding and assembly. Read our guide. Vacuum Casting Guide. Vacuum casting .At Post Precision Castings, Inc. our in-house tooling and casting machining services are available to maximize our speed and efficiency in fulfilling our customers orders. Making use of sinker EDM and CNC vertical machining equipment, we can build new tools, modify and repair tools as needed, alter existing tools, and produce a metal or wax sample for customer inspection. Sustainability in manufacturing processes: practices performed in metal forming, casting, heat treatment, welding and electrostatic painting August 2019 International Journal of Sustainable .

Sheet metal fabrication is a multi-faceted process that involves transforming flat metal sheets into complex 3D structures. This transformation is achieved through a series of cutting, bending, punching, welding, and finishing operations, often aided by advanced machinery and skilled craftsmanship. The versatility of sheet metal allows it to be . Dawang Metals is a one-stop metal fabrication supplier of castings, machining, and welding parts for global customers since 1998. With our own certified factories and elite network of services in Liaoning, China, we specialize in producing OEM parts in stainless steel, alloy steel, carbon steel, ductile and gray iron, and other metals.The machining process is a key fabrication technique. Machining is a subtractive manufacturing process wherein the metal is removed from the workpiece to create the desired shape. In this blog, we will discuss different machining processes, the materials used in metal machining, and why you should consider fabrication as a service for your .

best small cnc router machine

best steel bento box

The ultra-thin profile of the light and the slim driver junction box make it easy to fit into your ceiling without interfering with anything else. Quick wire connections and push spring-loaded clips make installation a breeze.

expertise in metal fabrication processes machining castings welding edm etc|Electrical Discharge Machining: Process, Types, and Application