expanding process in sheet metal Find Expanded sheet metal at Lowe's today. Shop sheet metal and a variety of hardware products online at Lowes.com.

In this article, I have listed the different tools you can use for cutting metal, the type of metal supplies you can cut with each of them and the pros and cons of each tool. Snips function like scissors and are one of the best manual means of cutting sheets of metal.

0 · stainless expanded metal sheet 4x8

1 · expanded steel sheets near me

2 · expanded metal sheets near me

3 · expanded metal sheets 5x8

4 · expanded metal sheet 4x8 feet

5 · 4x8 sheet of expanded metal

6 · 4x8 expanded steel sheets

7 · 4x8 expanded metal near me

These large green boxes are called pad-mounted transformers and caution must be practiced around them. What is a pad-mounted transformer? Pad-mounted transformers work .

stainless expanded metal sheet 4x8

This article dives into the fascinating world of metal expansion methods, explaining various techniques like bulge forming and hydraulic bulging. You'll discover how these processes transform metal sheets into complex .

expanded steel sheets near me

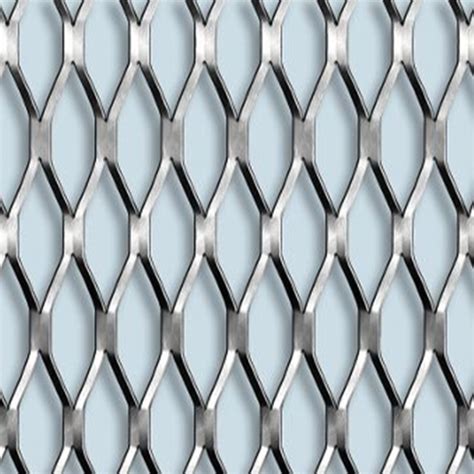

Also known as expanded metal mesh or expanded mesh, this material stands out due to its characteristic structure: an open and intertwined network of opening patterns. This . Expanded metal is a type of sheet metal that has been cut and stretched to form a regular pattern of diamond mesh-like material. Commonly used for machine safety guards, grates, glass protection. Expanded Metal (Ex .

The concept of expanded metal sheet arises from the understanding that metals have the ability to change their size—expanding and contracting—under different conditions. These changes are primarily .The Expanding-Shrinking Process – when contoured transitional Areas are required . The expanding-shrinking process is an unique and economical means of forming a wide range of parts. For some applications, the principles of both .Find Expanded sheet metal at Lowe's today. Shop sheet metal and a variety of hardware products online at Lowes.com.

The metal is then put through the expanding machine to go through the process of becoming expanded metal. This process involves using a row of small knives in the machine to make slits in the metal. The metal is .

Expanded metal is a type of sheet metal that has been cut and stretched to form a regular pattern of diamond mesh-like material. Commonly used for machine safety guards, grates, glass protection. . This process allows it to be expanded up to 10 times its original size, while losing up to 80 percent of its original weight per square foot and .The metal sheet can be expanded up to ten times its original width, and the final product is lighter per meter and stronger per kilogram than its original sheet. No material is lost in the manufacturing process. . Five steps in the manufacturing process . The metal sheet advances between the blades one strand width beyond the lower.

expanded metal sheets near me

expanded metal sheets 5x8

custom cast machine parts factory

Uses of Expanded metal sheet. Across industries, expanded metal sheet provides strength and versatility. Because the die-cutting process is adjustable, the expanded metal sheet is ripe for decorative applications such as sculptural artworks, architectural screening, and other commercial designs. The following is a partial list of expanded metal .

Flattened Expanded Metal. Flattened expanded metal is produced by cold rolling expanded metal to flatten it. It is chosen when a smooth surface is required. The flattening process generally elongates the length of the sheet by 5%. Hexagonal Expanded Metal. Hexagonal expanded metal has hexagonal openings instead of the usual diamond ones.

In the galvanizing process, the expanded metal sheet is immersed in molten zinc, which forms a protective zinc coating. This coating helps safeguard the mesh from corrosion. However, due to the high temperatures involved, this method has limitations on the dimensions of the expanded metal that can be galvanized. Very fine meshes are generally .Expanded metal mesh starts as solid sheet of metal which is then simultaneously slit and stretched along its length. The slits open up to create the diamond mesh pattern. No metal is lost in the expanding process and the resulting expanded metal mesh is lighter per metre and stronger per kilogram than the original sheet metal. Walkway mesh that complies with AS 1657 is a .

Raised expanded metal sheet is a finished product when it comes off the press after being cut and expanded. Raised expanded metal sheet features alternating ridges formed by overlapping metal strips that create a diamond pattern. . The cold rolling process flattens the metal and helps to make it flatter, thinner, and longer. Flattened .Metalrise is a supplier of expanded metal sheets in the Philippines. . Expanded metal is a metal produced from a solid metal sheet. That goes through a process of cutting and stretching resulting in a mesh with diamond-shaped spaces.

Overall, hydraulic ring expanders are an effective tool for expanding metal rings quickly and uniformly, with minimal risk of damaging the ring or causing uneven expansion. The ring expanding process minimizes material thinning and virtually eliminates the stress point issues associated with traditional rolling and machining.Perforated, expanded and stamped sheet metal Certifications. ISO 9001. Stock in perforations and common meshes. 2000x1000 and 3000x1500. Can be customised. . In our manufacturing process with punching, we shape the metal with our presses and dies adapted to each product, which enables us to create textures on the metal surfaces with the . Expanded metal mesh is a metal sheet that is slit and stretched by machine to form a three-dimensional mesh of the same size and shape. . A stable response through the whole deformation process .

To produce expanded metal, a sheet or plate is simultaneously slit and stretched. This process expands the cuts into diamond shaped holes of uniform size and shape. Because no metal is lost in the expanding process, expanded metal is cost . Sheet metal expanding is a specialized process within sheet metal forming that involves stretching the metal to create a mesh-like pattern. This technique enhances the sheet metal’s flexibility and strength, making it . While this goes very well with the expanded process, some climes may warrant more extra layers. Temperature and Exposure: . Perforated and expanded metal are two sheet metals with equal uses as following. Perforated .

Expanded metal is made from sheet metal using a shearing process. It is placed under the set of knives, cut and at the same time stretched - without penetrating - forming a uniform grid with a perfect pattern. Therefore the first step in any sheet metal process is to cut the correct shape and sized blank from larger sheet. . It’s a recent area of research in the wide field of metal forming technologies which is expanding the limits for applying metal forming towards micro technology. The major sheet metal processes for micro forming are shearing .Crown Bolt - 24 in. x 3/4 in. x 24 in. Metal Plain Expanded Sheet - For general applications. Can be welded. Commonly used for barbeque grills, chimney screens and pet cages. . Scale indicates the complexity of the bending and forming process. About This Product. This expanded sheet metal can be altered in shape and cut with proper equipment .

In raised expanded metal, the metal sheet is subjected to a process of slitting and stretching, creating a pattern of raised diamond-shaped openings. . The expanding process does not alter material thickness; however, the flattening process does. The average material thickness is reduced by 10-20% after flattening. Considering that the mesh .

Basically, the manufacturing process of an expanded metal mesh begins when a solid sheet advances through traction rollers at a distance equivalent to the width of the vein and enters a set of perforating scissors (Fig. 2). When the upper blades meet the straight and stationary lower blades, the solid sheet is cut at a right angle in the .

Standard expanded metal is available in various materials, including aluminum, stainless steel, and carbon steel. Flattened Expanded Metal. The process of flattening involves cold-rolling the standard expanded metal to reduce its thickness. Flattened expanded metal has a smoother surface and offers a lower profile than standard expanded metal.Standards for Expanded Metal Selection, Manufacture & Application Expanded Metal Manufacturers Association, a division of NAAMM (National Association . The die then ascends, returning to its original position and repeats the process until the full sheet or coil of expanded metal is completed. In any die pattern, the strand width and the depth .

Expanded metal sheet provides strength and versatility across industries. Since the die-cutting process is adjustable, expanded metal sheet is ripe with decorative possibilities, whether for sculptural artworks, architectural screening, or other commercial designs. Here’s a non-exhaustive list of expanded metal sheet applications:Steelco is the most trusted supplier for metal sheets Qatar. Buy expanded metal sheet in Qatar that are best in range and can be used for wide range of construction purposes. . In the expanding process, the metal can be expanded up to ten times its original size, lose up to 80% of its original weight per square foot, and still retain form and . Expanded metal, on the other hand, may have leftover sharp edges caused by the expanding process where the roller simultaneously flattens and cuts the steel plate being turned into expanded metal. However, these sharp edges can be easily remediated by using a sanding process , electropolishing, or even applying a coating to the basket to .

expanded metal sheet 4x8 feet

4x8 sheet of expanded metal

It's called "diamond plate" and, unless used for flooring, it is primary just used to look "cool". The pattern was originally designed/intended to provide traction on metal floors (like on some .

expanding process in sheet metal|stainless expanded metal sheet 4x8