cnc lathe parts moving If small parts start to bow up as they are cut they can move. If you're cutting nasty sheeting this is more likely to happen. The thinner the skin, the better. I leave a .03" skin and . Itmight be possible to support the box from aluminum soffit, but certainly not from vinyl soffit, which would probably sag under the weight of the light fixture. One Solution: It's possible to mount the box on the wall just below soffit.

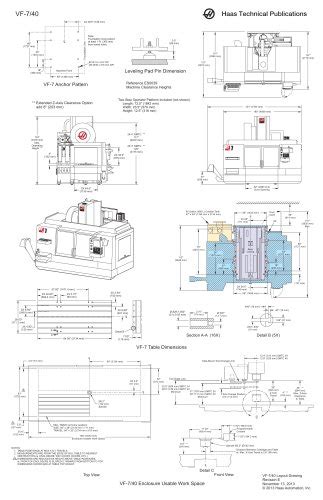

0 · haas cnc parts catalog

1 · cnc replacement parts manufacturer

2 · cnc machine parts list pdf

3 · cnc machine parts catalog

4 · cnc lathe replacement parts

5 · cnc lathe parts list

6 · cnc lathe parts catalog

7 · cnc lathe headstock

Learn what size electrical box screws you need for your next project with our handy guide. We'll cover everything from standard sizes to metric measurements, so you can .

Moving a CNC machine is no easy feat. In this guide, we will discuss with you the steps you should take to guarantee the safe relocation of your CNC machine. If small parts start to bow up as they are cut they can move. If you're cutting nasty sheeting this is more likely to happen. The thinner the skin, the better. I leave a .03" skin and .

A CNC lathe(CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the .Begin by disconnecting the CNC machine from its power source and carefully disassembling any detachable parts, such as the tool changer, spindle, and coolant system. As you remove each .Toolroom lathes’ precise movements and figure make them indispensable when working on intricate components requiring tight tolerances. Turret lathes figure excel in mass production .

CNC lathes don't have Z-axis brakes, and thus the turret can drift in Z, especially on the truck as it ascends or descends a grade. Plus, you damn sure don't want the turret . Rigging is just solid planning and careful execution. And the right equipment. I helped another member here move a 10k lb CNC lathe from his parking lot into the shop a .

To determine the parts of a CNC lathe machine, it is recommended to study the user manual and breakdown images of your machine. You should have a clear understanding .

A CNC lathe is a precision tool that uses computer programming to control the motion and operation of a cutting tool. The cutting tool is held in a tool turret and moves along the workpiece to create the desired shape or . Moving a CNC machine is no easy feat. In this guide, we will discuss with you the steps you should take to guarantee the safe relocation of your CNC machine. If small parts start to bow up as they are cut they can move. If you're cutting nasty sheeting this is more likely to happen. The thinner the skin, the better. I leave a .03" skin and reduce the final cutout speed by 50%. They are cutout at 250ipm. Small parts are always cut first so they have maximum vacuum. Most software can do this.

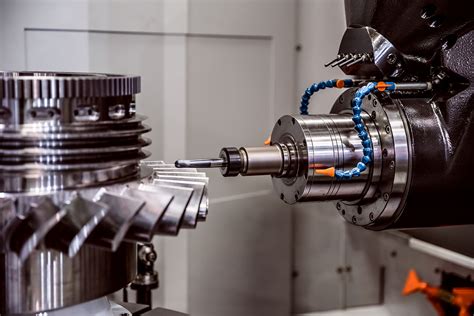

This article will focus on defining CNC lathes, identifying the lathe machine’s parts, examining how each element works, and advising about optimal use. Here is an image of how a CNC lathe looks with major parts labeled:

A CNC lathe(CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by coded instructions fed to a computer.Begin by disconnecting the CNC machine from its power source and carefully disassembling any detachable parts, such as the tool changer, spindle, and coolant system. As you remove each component, make sure to label it properly to avoid confusion during reinstallation.Toolroom lathes’ precise movements and figure make them indispensable when working on intricate components requiring tight tolerances. Turret lathes figure excel in mass production settings where rapid tool changes optimize cycle times. CNC lathes don't have Z-axis brakes, and thus the turret can drift in Z, especially on the truck as it ascends or descends a grade. Plus, you damn sure don't want the turret moving when the riggers have the lathe on forks up in the air, .

Rigging is just solid planning and careful execution. And the right equipment. I helped another member here move a 10k lb CNC lathe from his parking lot into the shop a couple of weeks ago. No forklift, just toe-jacks, skates and .

To determine the parts of a CNC lathe machine, it is recommended to study the user manual and breakdown images of your machine. You should have a clear understanding of each component before progressing to cutting metal. A CNC lathe is a precision tool that uses computer programming to control the motion and operation of a cutting tool. The cutting tool is held in a tool turret and moves along the workpiece to create the desired shape or features. Moving a CNC machine is no easy feat. In this guide, we will discuss with you the steps you should take to guarantee the safe relocation of your CNC machine.

If small parts start to bow up as they are cut they can move. If you're cutting nasty sheeting this is more likely to happen. The thinner the skin, the better. I leave a .03" skin and reduce the final cutout speed by 50%. They are cutout at 250ipm. Small parts are always cut first so they have maximum vacuum. Most software can do this.

This article will focus on defining CNC lathes, identifying the lathe machine’s parts, examining how each element works, and advising about optimal use. Here is an image of how a CNC lathe looks with major parts labeled:

A CNC lathe(CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by coded instructions fed to a computer.Begin by disconnecting the CNC machine from its power source and carefully disassembling any detachable parts, such as the tool changer, spindle, and coolant system. As you remove each component, make sure to label it properly to avoid confusion during reinstallation.Toolroom lathes’ precise movements and figure make them indispensable when working on intricate components requiring tight tolerances. Turret lathes figure excel in mass production settings where rapid tool changes optimize cycle times.

CNC lathes don't have Z-axis brakes, and thus the turret can drift in Z, especially on the truck as it ascends or descends a grade. Plus, you damn sure don't want the turret moving when the riggers have the lathe on forks up in the air, . Rigging is just solid planning and careful execution. And the right equipment. I helped another member here move a 10k lb CNC lathe from his parking lot into the shop a couple of weeks ago. No forklift, just toe-jacks, skates and . To determine the parts of a CNC lathe machine, it is recommended to study the user manual and breakdown images of your machine. You should have a clear understanding of each component before progressing to cutting metal.

haas cnc parts catalog

cnc machine limitations

cnc machine lifespan

Sconce back plate is 4" round. Is this appropriate for a sconce with a round back plate? Yes, that's the correct box. It's a 4" octagon but measure it and you'll see it's less than 4". That is a 4" octagonal not a square. That is .

cnc lathe parts moving|cnc lathe parts list