how to deburr holes in sheet metal There are many methods to sheet metal deburring that can be used in these situations. These are normally perforated using manual tools or automated equipment, and the increase of sheet metal use has also allowed each . Easily installs by attaching directly to SCH 40 or SDR 35 pipe. Our unique channel split design enables an equal split of the waste stream. Additionally the valve can be set for equal distribution (factory setting) or all distribution to the right or left.

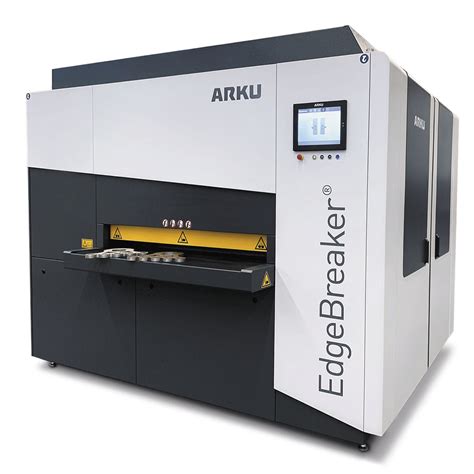

0 · metal deburring machine

1 · how to deburring metal

2 · how to deburr steel

3 · deburring tool

4 · deburring metal mold

5 · deburring metal cutting

6 · chemical deburring tool

7 · best way to deburr metal

But, in all cases the junction boxes are not covered and are not fastened to anything. They were just left lying on the insulation. Here's a couple of pictures of what I found:

Hole Deburring You can use this method to deburr the inner parts of a hole. A spring-loaded cutting tool mounted on a spindle is positioned so that it can move through the hole smoothly and cut the burr without scratching or otherwise .23 Different Methods for Deburring. Mass Finishing. Manual Deburring. Semi-Automatic Deburring. Brush Deburring. Punch Press Deburring. Magnetic Polishing Deburring. Thermal .

Hole Deburring; This technique can be applied to deburr the interior of a hole. The positioning of a spring-loaded cutting tool on a spindle allows it to pass through the hole .There are many methods to sheet metal deburring that can be used in these situations. These are normally perforated using manual tools or automated equipment, and the increase of sheet metal use has also allowed each .The 5 most common ways of removing burrs and edges are vibratory finishing, barrel tumbling, manual deburring, thermal energy deburring, and electromechanical deburring. Manual deburring: A skilled craftsperson can . Deburring sheet metal edges is an essential step in achieving high-quality workmanship in metal fabrication. It involves removing the sharp, rough edges left after cutting, which not only enhances the appearance of the .

Hole Deburring. As the name suggests, this method is used when deburring is needed on the inner part of a hole. There are a variety of tools to apply this method available in the current market, but they usually have the .

1. DEBURRING BY HAND. Using hand tools to remove burrs is manual deburring, one of the earliest and most basic methods of deburring. In small shops or for small parts where automation could be more practical, this . Without a doubt, you need to remove burrs from your sheet metal edges. When you have smooth edges on your metal sheets, you’ll be able to manipulate them in a safer manner. By removing the edge burrs we reduce .

Holes are drilled so let's get them cleaned up and ready for fasteners. Paul Dye explains the process of deburring holes and edges in this episode.This serie.

Theres no such thing as a burr-free drilled hole, especially not in sheet metal. There will always be a burr, the only thing that changes is how much of a burr there is. . There are plenty of different options for deburring a hole thats hard to access. Simplest way would be a handheld deburring tool with the proper blade:

Hole Deburring. As the name suggests, this method is used when deburring is needed on the inner part of a hole. There are a variety of tools to apply this method available in the current market, but they usually have the same configuration. A cutting tool is spring-loaded and mounted on a spindle. The cost of labor is high, the efficiency is low, and it can be challenging to remove cross holes and complex workpieces. 13. Deburring with hand tools. . My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am constantly .

Many builders question the need to deburr or chamfer the sharp metal edges on all the sheared metal skins and formed parts before they are really needed. However, I find it to be a lot easier and quicker to perform most preparatory, and like operations, at one time. Deburring drilled holes and deburring cut or sheared metal edges are good examples.Discover the secrets to creating perfect countersink holes in sheet metal with our easy-to-follow guide, designed for beginners and pros! . Use a deburring tool or a more significant drilling bit gently around the hole’s edge. Smoothing Edges: To achieve a smoother surface, lightly sand around the hole’s edge. Be gentle when using fine .

How to Enlarge holes in Sheetmetal, using Step Drill bits Thanks for WatchingYOU CAN ALSO FIND ME ON THE FOLLOWING:PINTEREST: http://www.pinterest.com/davidh. of the hole and it takes more metal removal to debur the hole. TeachMePlease Diamond. Joined Feb 11, 2014 Location FL. Dec 4, 2015 . The O-flute countersinks are my favorite deburring tool for drilled holes. They leave the best, cleanest chamfer by far of all the methods I have tried. BUT not all O-flutes are created equal.

Sheet Metal Deburring Tool - http://amzn.to/2gPPubm*As an Amazon Associate I earn from qualifying purchases*On this episode of "you need this tool" I review .For our robotics we have a local company laser cut 12 gauge 304 stainless steel sheets. These are used for both the top surface of the robotics (lot of holes and cutouts) and for two spinning platters.See the video below for context. The company that laser cuts it doesn't so any finishing. How to Deburr Metal Parts: Step by Step. Deburring metal is a meticulous process that demands precision and attention to detail. Here’s a step-by-step to efficiently deburr metal parts. 1. Pre-deburring Steps. Before diving into the deburring process, proper setup and calibration are crucial. Securely place the metal part in the deburring .

Leaving no sharp edges behind makes the hand-punch ideal for projects where you don’t want to deal with deburring. Thicker materials require a bench-mounted punch or knockout punch to provide enough force to pierce through the sheet metal. . Instead of drilling into the sheet metal, a hole saw will cut the hole at its exact size like a .

Seconding a Cogsdill Burr Away like tool. You can even set them up to run in cycle so it can just deburr while running. Had a job once where we had to deburr 1500-2500 1/4 holes on a turned shaft. We would load up the burr away on a drill press and pay a greenhorn to sit and deburr all day long. Came out nice. Suitability for Different Types of Sheet Metal. Deburring: Essential for parts with sharp edges and complex geometries. Polishing: Suitable for achieving reflective finishes on flat and contoured surfaces. Buffing: Ideal for .

Double deburr tool if the thickness is like less than 4-5mm. Can be a bit of a pain if the corrugating is tight. Flap wheel on a grinder is pretty quick too, one very fast run along each edge to chamfer the burr onto the outside thickness of the steel then a very light and fast final pass on the flat outside to smooth it. This technique can be applied to deburr the interior of a hole. The positioning of a spring-loaded cutting tool on a spindle allows it to pass through the hole smoothly and remove the burr without scuffing or otherwise harming the surface. Specific cutting instruments feature a tapered tip that, when it goes through a hole, forms a chamfer .

While some holes in sheet metal may be cut very cleanly, most will require slight finishing for best results. . To use a deburring tool, rest the tool's sharp blade against the edge of a newly .For a fast and efficient way of deburring internal holes the XEBEC Extended Deburring Tools are ideal for accurate precision cross hole deburring. The burr is carefully removed without damaging the drill holes. The elastic shaft with 2mm flexible radius reduces the .We produce a part that has several oval holes that need deburring after machining. We are currently doing them manually but I’m looking for a solution to deburr the holes with an electric tool to speed up the process. . I work mainly with sheet metal, but after parts get punched we palm sand the sharp edge with 80grit. It's enough for the .

Electromechanical Deburring: The burred part of the metal sheet is dipped into a glycol solution or salt solution and exposed to electrical current. This type of deburring is perfect for small metal pieces that may be burred in hard-to-reach places. Thermal Energy Deburring: This is also one of the most discussed methods of sheet metal . Deburring sheet metal edges can present various challenges, but with the right tools and techniques, these challenges can be overcome. Some common challenges include: Tight corners and complex contours: Sheet metal components often have intricate shapes with hard-to-reach areas. It can be challenging to remove burrs from these tight corners and . Section 2: Deburring in Sheet Metal Parts Section 2: Deburring in Sheet Metal Parts Definition and Types of Burrs. Deburring is the process of removing small, unwanted protrusions or burrs that form on the edges of sheet metal parts during manufacturing processes like cutting, drilling, and stamping. Burrs can negatively affect the performance .

Do-it-yourself homeowners find working with PVC (polyvinyl chloride) plumbing pipe relatively simple since it requires no special skills or tools. PVC pipe is less expensive, lighter in weight and will not rust or corrode like metal plumbing pipe. Working with PVC pipe requires cutting various lengths with a hacksaw.But we have to deburr the inside and outside by hand and it's a huge bottle neck. We tried drilling, then changing the tool to a deburring tool but the hole never line up precisely and we were breaking too many bits and misaligning holes. We tried a combo drill bit/deburr tool, like the ones you use for woodworking but they don't last. Whitney Tool Company (Bedford, IN) recently took a leadership position in the manufacture of deburring tools through the acquisition of Cogsdill Enterprises, Inc. (Commerce Township, MI). Cogsdill is the developer and patent holder of the Burr-Zit tool. Burr-Zit is the original clothespin type deburring tool that can deburr both sides of a drilled, punched or .In addition to deburring, barrel tumbling can be used to de-flash, de-scale, clean, or remove rust from metal parts. Choosing a Deburring Method Each metal deburring method has benefits and drawbacks for different applications. Your best method of choice will depend on the type of metal, the size and shape of the component, and the finish you .

metal deburring machine

how to deburring metal

Nossos centros de usinagem CNC oferecem tecnologia superior e equipamentos personalizados para a produção altamente eficiente de móveis, componentes e para o processamento de plásticos e madeira maciça.

how to deburr holes in sheet metal|best way to deburr metal