16 gauge sheet metal roller These electric powered slip rolls come standard with 3 driven rolls and are . What is a Junction Box? A junction box is simply a small enclosure for electrical connections. It protects these electrical connections from the environment around them and accidental contact. The box itself isn't anything specific. They are typically made of metal or plastic and are attached to a beam or possibly the drywall.

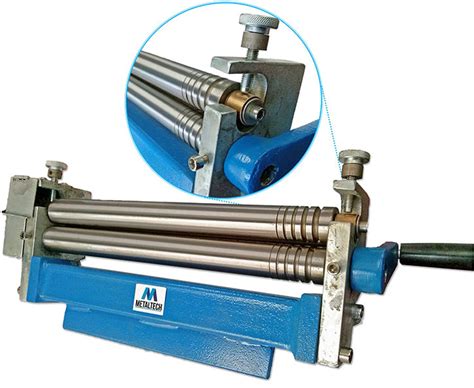

0 · slip rolls metal fabrication

1 · sheet metal edge shaping rollers

2 · metal slip roller for sale

3 · manual sheet metal rollers

4 · heavy duty slip roller

5 · flat stock metal roller

6 · electric sheet metal slip roller

7 · 1 inch diameter slip rollers

It is built out of 22 gauge, mirror finish stainless steel and is fully TIG welded with lifetime limited warranty on the welds. Smoky Lake has built the best maple syrup pans in the world for the past 10 years. A valve and dial thermometer are included.

Slip rolls or plate rolls are designed to form sheet metal into curved panels or cylinders. These sheet metal rollers are available as manually operated or powered, and many include wire .These electric powered slip rolls come standard with 3 driven rolls and are .Gauge: 16-Gauge mild steel; Minimum roll size: 3" Rod/wire grooves diameter: 5/16", 3/8", and 1/2" Footprint: 58-1/2" W x 20-1/2" D; Overall size: 86-1/2" W x .Depth Bead Roller, Sheet Metal, 16-Gauge Capacity, Throat Depth 36 in., Includes Dies, Each. Part Number: BAI-1000924. 5.0 out of 5 stars

,416.999.99,099.99,899.00

,199.99 The Baileigh SR-5016M Slip Roll has a forming width of 50 inches with a capacity of 16-gauge mild steel. This is a three-roll machine with two driven rolls that are made of .0.29

,999.00,916.37Sheet metal rollers are versatile machines that can cut, bend, and curve sheet metal with ease. They are commonly used in the fabrication industry to create cylindrical shapes, bends, and curves in sheet metal.

The Baileigh SR-5016E Powered Slip Roll is a great roller for any HVAC shop or general fabrication shop when sheet metal forming 16-gauge mild steel is required. This slip .Slip rolls or plate rolls are designed to form sheet metal into curved panels or cylinders. These sheet metal rollers are available as manually operated or powered, and many include wire grooves for bending solid rod.Gauge: 16-Gauge mild steel; Minimum roll size: 3" Rod/wire grooves diameter: 5/16", 3/8", and 1/2" Footprint: 58-1/2" W x 20-1/2" D; Overall size: 86-1/2" W x 37" D x 48" H; Approximate shipping weight: 920 lbs. FEATURES: Hands-free operation; Forward/reverse foot pedal controls with emergency stop button; Proximity safety stopDepth Bead Roller, Sheet Metal, 16-Gauge Capacity, Throat Depth 36 in., Includes Dies, Each. Part Number: BAI-1000924. 5.0 out of 5 stars

slip rolls metal fabrication

The Baileigh SR-5016M Slip Roll has a forming width of 50 inches with a capacity of 16-gauge mild steel. This is a three-roll machine with two driven rolls that are made of polished carbon steel offering years of reliable service.Sheet metal rollers are versatile machines that can cut, bend, and curve sheet metal with ease. They are commonly used in the fabrication industry to create cylindrical shapes, bends, and curves in sheet metal. The Baileigh SR-5016E Powered Slip Roll is a great roller for any HVAC shop or general fabrication shop when sheet metal forming 16-gauge mild steel is required. This slip roll has three forming rolls with a width of 51 inches, and features two driven rolls for more power.These rollers use their electric motor to turn their dies and add beads to sheet metal. They produce more uniform beading and bead heavier-gauge sheet metal than manual models.

Woodward Fab provides electric powered slip roll for production and forming of curved parts and tubes made of 16-gauge and lighter sheet metal. Buy power slip roll to handle greater capacities.

National's NR7216 6 ft power roll features forward and reverse drum switch, quick release upper roll, positive chain drive, and heavy duty gear box.

50" Slip Roll ; 16 Gauge ; Over All Dimension: 71"L x 18"W x 18"H ; Quantity: 1; › See more product detailsSlip rolls or plate rolls are designed to form sheet metal into curved panels or cylinders. These sheet metal rollers are available as manually operated or powered, and many include wire grooves for bending solid rod.

Gauge: 16-Gauge mild steel; Minimum roll size: 3" Rod/wire grooves diameter: 5/16", 3/8", and 1/2" Footprint: 58-1/2" W x 20-1/2" D; Overall size: 86-1/2" W x 37" D x 48" H; Approximate shipping weight: 920 lbs. FEATURES: Hands-free operation; Forward/reverse foot pedal controls with emergency stop button; Proximity safety stopDepth Bead Roller, Sheet Metal, 16-Gauge Capacity, Throat Depth 36 in., Includes Dies, Each. Part Number: BAI-1000924. 5.0 out of 5 stars

The Baileigh SR-5016M Slip Roll has a forming width of 50 inches with a capacity of 16-gauge mild steel. This is a three-roll machine with two driven rolls that are made of polished carbon steel offering years of reliable service.

Sheet metal rollers are versatile machines that can cut, bend, and curve sheet metal with ease. They are commonly used in the fabrication industry to create cylindrical shapes, bends, and curves in sheet metal.

The Baileigh SR-5016E Powered Slip Roll is a great roller for any HVAC shop or general fabrication shop when sheet metal forming 16-gauge mild steel is required. This slip roll has three forming rolls with a width of 51 inches, and features two driven rolls for more power.These rollers use their electric motor to turn their dies and add beads to sheet metal. They produce more uniform beading and bead heavier-gauge sheet metal than manual models.Woodward Fab provides electric powered slip roll for production and forming of curved parts and tubes made of 16-gauge and lighter sheet metal. Buy power slip roll to handle greater capacities.

National's NR7216 6 ft power roll features forward and reverse drum switch, quick release upper roll, positive chain drive, and heavy duty gear box.

4 x 1 4 sheet metal screws

sheet metal edge shaping rollers

CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, known as the blank or workpiece, to produce a custom-designed part 1.

16 gauge sheet metal roller|heavy duty slip roller