cnc milling machine process CNC milling is a machining process that combines the traditional milling manufacturing method with a computer. Milling is a very important process here at Xometry and you can get an instant quote on milling any time you . P4W operate industry-leading screw machines, automatic lathe and CNC machine lathe turning units to manufacture high-value CNC turning parts and precision turned components, custom fasteners, and special fixings for a variety of industries.

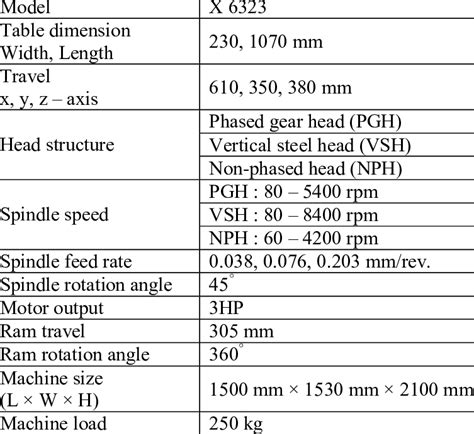

0 · specifications of cnc milling machine

1 · milling process step by

2 · milling advantages and disadvantages

3 · cnc milling diagram

4 · cnc machine work needed

5 · cnc machine process step by

6 · basics of the cnc mill

7 · advantages and disadvantages milling process

Boasting rugged durability, high-quality components, and the sophistication of European design, the CEO Tech from TW Steel is a classy looking oversized watch that’s oozing with masculine style. Each watch comes .

CNC milling is a subtractive manufacturing process that combines traditional milling with computer numerical control (CNC) technology. It involves using a rotating cutting tool to remove material from a solid block of metal, .

CNC milling is a computer-controlled process and a specific type of CNC machining that involves cutting a block of material mounted on a machine bed with different rotating multi-point cutters to achieve the desired shape and . CNC milling is a machining process that combines the traditional milling manufacturing method with a computer. Milling is a very important process here at Xometry and you can get an instant quote on milling any time you .Here’s how the CNC milling process works without getting too nerdy: Programmed instructions call the shots: Unlike manual milling, where someone’s arm strength and eyeballing skills are .CNC milling is a subtractive manufacturing process in which a computer-controlled rotating cutting tool selectively removes portions of a block of material to form a desired object. Milling technology existed as a manufacturing .

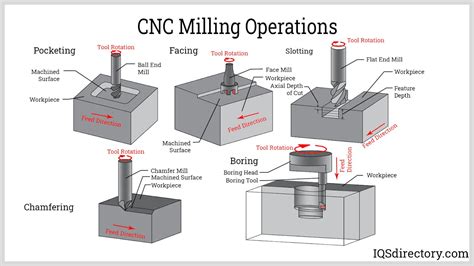

CNC Milling Process: This entails the use of computer numerical control (CNC) machinery to accurately remove material from a workpiece. The essential principles involve translating a digital design into numerical codes . At its core, CNC milling revolves around a straightforward principle: using computer-controlled machinery to cut, shape, or modify materials. Unlike manual methods, where a craftsman would laboriously cut and shape .

CNC milling, an abbreviation for Computer Numerical Control milling, is a transformative manufacturing process governed by computer software to direct machinery movement. Unlike additive processes such as 3D printing, .CNC milling is a subtractive manufacturing process that uses computer-controlled, multi-point, rotary cutters to remove material from a workpiece and produce a custom-designed part or product. The process begins with a 3D .

CNC milling is the removal of material from a work piece using a combination of special cutting tools and computer programs. A milling machine is used in this process to achieve the desired shape and size of the part with .

CNC Milling and Turning Working Process. Perfect Machines Technology#toolscutting, #cncturning, #machinist Disclaimer: CAD/CAM SOLUTIONS is not affiliated w. 3. CNC (Computer Numeric Control) Computer Numeric Control (CNC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium (computer command . Machine Setup: The CNC milling machine is prepared with the appropriate cutting tools and the raw material is secured. 4. Machining Process: The CNC mill executes the G-code, precisely moving the cutting tool to remove material and shape the work piece. 5. Finishing: After machining, the part may undergo additional finishing processes for .

CNC mills are often classified by the number of axes on which they can operate or spindle directions. 1. Vertical Mill. A vertical mill or milling machine’s spindle axis is vertically oriented, which means the cutting tools on the spindle will shape the materials vertically, and the cutters move while the workpiece remains stationary, the machines can cut into the part easily. CNC Milling Machines. Milling machines are the most common CNC equipment. They use a multi-point rotating cutting tool attached to a CNC-controlled spindle. . It is changing to process hard materials and the machine is also noisy. Applications. CNC counting is ideal for parts with flat surfaces; Wood, metal, and plastic furniture and . The Components of a CNC Milling Machine. On a CNC machining center, the workpiece is mounted in a fixed position on a work table while the tool is moved around it. Embarking on a journey into the world of CNC milling requires familiarizing oneself with the primary components of the machine. . The 5-Axis CNC Milling Process. Finally, stepping . The sound of chips hitting the machine has people flocking to the Ibarmia stand at AMB 2024!! Whether it’s the T series or the Z series, Ibarmia’s Gen2 models have so many different options you wouldn’t normally see at any exhibition. From standard milling and turning all the way to skiving, eccentric turning, elliptic turning, [.]

If we compare to the manual milling machine process the CNC milling process feeds the movable workpieces with the rotation of the cutting tool rather than moving against it. So, the basic steps for the milling machine are as follows, Design of CAD model, Converting CAD to CNC program; With CNC machines, milling has become an essential component of modern metalworking and manufacturing industries. The ability to automate milling processes and achieve unparalleled precision has significantly advanced the capabilities of milling technology. . Milling Process Milling Operations Milling Machine Setup; Rotation of cutter on . A CNC milling machine is a sophisticated piece of equipment that automates the process of cutting and shaping materials, such as metal, plastic, or wood. Standing for Computer Numerical Control, CNC milling leverages computerized systems to control the movement and operation of the cutting tools with extreme precision. The thermal analysis of the CNC structure will be developed in a future work. 3.5. Finite element analysis (FEA) The present study develops a finite element model along with an end milling machine structure model to analyze the .

CNC milling machines use computerized controls and rotating cutting tools to remove material from a workpiece. There are two main types - horizontal and vertical milling machines - classified based on the orientation of the spindle axis. . CNC Milling Machine • CNC milling, is a machining process which employs computerized controls and . What is CNC Milling? CNC milling is an automated, subtractive manufacturing technology designed to remove material in a controlled, pre-programmed manner to produce parts. Almost any material can be processed using CNC milling, including metal, plastic, and wood.CNC mills require specialized operators, but once programmed, they can produces parts .

CNC milling is a process used in manufacturing that involves the use of computer numerical control to automate the operation of milling machines. This process allows for the precise cutting, shaping and drilling of materials by .CNC milling is a machining process that combines computer numerical control machining systems and a multi-point cutting tool or milling cutter. As one type of CNC machining, it involves mounting the workpiece on a machine bed and .The last step in the CNC machining process involves a final inspection of the finished parts for quality assurance. Any defects or imperfections are addressed and rectified. . Equipped with 3-4-5 axis CNC milling and CNC turning machines, which enable us to handle even more complex parts with high precision. However, virtual simulations of CNC milling processes can be further enhanced by incorporating trained machine learning (ML) models to identify optimal input process parameters autonomously. The ability to identify optimal parameter permutations enables manufacturing companies to reduce process time while maintaining product quality.

With the rapid advancements in CNC milling technology driven by Industry 4.0, the future of CNC milling hinges on the development of emerging technologies and their impact on the manufacturing landscape. As CNC milling machines become more accurate, efficient, and user-friendly, they are poised to revolutionize various aspects of manufacturing and contribute to a .

specifications of cnc milling machine

The dataset provided is a collection of real-world industrial vibration data collected from a brownfield CNC milling machine. The acceleration has been measured using a tri-axial accelerometer (Bosch CISS Sensor) mounted inside the machine.CNC milling machines are commonly used in modern manufacturing to precisely and ef ficiently process various complex curved components. The generation of toolpath trajectories is a critical step in the machining process of NC milling machines, directly impacting the quality and ef ficiency of part manufacturing.

CNC milling machines automate the production process, reducing the need for human intervention and thereby reducing errors. . CNC milling machines are the top-end option because they provide a high-precision solution to parts manufacturers. These machines are versatile and can handle various materials including metals like aluminum, steel . Pricing a CNC machine is a big step in this process. Having a tight budget is almost always a concern when setting up any machine shop. . Manufactured in California, this CNC milling machine offers the largest cutting work area out of all the machines we’ve reviewed.The CNC metal milling machine can process parts that cannot be processed by ordinary machine tools. For instance, the complex curved parts described by mathematical models, three-dimensional surface parts. High precision, stable and reliable processing quality. The pulse equivalent of the CNC milling equipment is generally 0.001mm, and that of .

Machine setup plays a crucial role in the milling process, ensuring that the milling machine is properly aligned and equipped for optimal performance. Setting up the milling machine involves several key steps that need to be executed meticulously to achieve accurate and efficient milling operations. Alignment

The OTMT 0T2213 mini mill is a small, compact benchtop milling machine with 1/2 HP and a 3.5” x 15” work table.. This benchtop milling machine has some great features that make it a useful addition to your workspace. For example, the head tilts 45 degrees from left to right, offering versatility and improved control for highly accurate cutting, milling, and engraving on your DIY . 2. Set up milling machine. Although CNC milling machines can automatically cut workpieces, certain aspects of the process still require machine operators. For example, the operator must fix the workpiece to the workbench and adjust the tool of the spindle. Modern milling machines have the ability to process with electricity.

cnc machine cutting tools

Built with a strong and durable steel frame and a versatile poly jacquard cover that slips right on, the Smart BoxSpring® is the picture of dependability for any mattress. All packed in a compact shipping box with everything included, even .

cnc milling machine process|milling process step by