easiest way to cut existing sheathing for electrical box I am not sure if they make a bit for Rotozips that will cut OSB, but I know it's the easiest/best way to cut holes in drywall for outlets. It leaves a nice clean opening and its easy . Sheet metal shearing is a fundamental fabrication process that involves slicing through metal sheets to separate them into different sizes and shapes. This technique uses a pair of sharp blades, one typically fixed and the other moving vertically, to exert a shear force across the metal sheet.

0 · installing electrical box in plaster

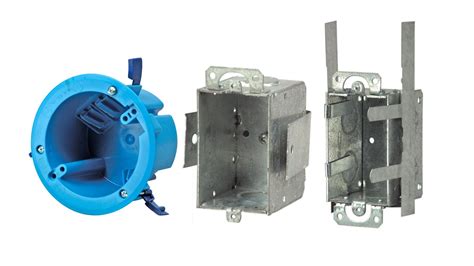

1 · installing electrical box in finished wall

2 · how to install electrical boxes

3 · how to cut boxes into walls

4 · electrical box installation instructions

5 · diy electrical box installation

6 · cutting boxes into existing ceiling

7 · cutting box into existing wall

Concealed or external flashing is typically made from sheet metals, bituminous-coated fabrics, plastic, or other waterproof membrane materials. Exposed flashing is commonly made from aluminum, copper, galvanized steel, zinc, lead, or terne. Sheet metal flashings are the most durable, thus their use in external/exposed conditions.

Drywall Trick- Easiest way for cutting electrical ceiling boxes wall outlets - YouTube. While on a project where the patio ceiling had been blown out during Hurricane Matthew. I wanted.

Cutting a Wall Box into Plaster. If existing house wiring is in good condition and an existing circuit has the capacity for an additional outlet, turn off the power, cut a hole in the wall, fish cable to . cutting the holes are easy, you can score with a diamond blade and then just tape with a hammer, or you can just drill a bunch of 1/4" holes around the outline of the box and . How to Install an Electrical Box in a Finished Wall. Follow these expert tips to install an electrical box into drywall or plaster without the need for wall studs or joists.

I am not sure if they make a bit for Rotozips that will cut OSB, but I know it's the easiest/best way to cut holes in drywall for outlets. It leaves a nice clean opening and its easy . Just wondering if electrical box holes should be cut through the exterior sheathing before or after the siding is on? We used to have them installed before the exterior finish .To get the insulation off this wire so that we can get to the conductors inside, the easiest way to avoid cutting yourself or scoring the wire on the inside is to get about 1½ inches of what’s sticking out of the box and just stab into it with a utility knife and cut away from you. Installing an old work box into an existing wall to add an outlet or wall switch is an easy project that requires just a few common tools that you may already own if you're familiar .

Drywall Trick- Easiest way for cutting electrical ceiling boxes wall outlets - YouTube. While on a project where the patio ceiling had been blown out during Hurricane Matthew. I wanted.Cutting a Wall Box into Plaster. If existing house wiring is in good condition and an existing circuit has the capacity for an additional outlet, turn off the power, cut a hole in the wall, fish cable to the location, and secure a remodel box (cut-in box) to the finish surface. cutting the holes are easy, you can score with a diamond blade and then just tape with a hammer, or you can just drill a bunch of 1/4" holes around the outline of the box and then finish it off with a few taps from your hammer.

How to Install an Electrical Box in a Finished Wall. Follow these expert tips to install an electrical box into drywall or plaster without the need for wall studs or joists. I am not sure if they make a bit for Rotozips that will cut OSB, but I know it's the easiest/best way to cut holes in drywall for outlets. It leaves a nice clean opening and its easy to learn how to do. Just wondering if electrical box holes should be cut through the exterior sheathing before or after the siding is on? We used to have them installed before the exterior finish because the electrician would come to do the rough in before the siding was on. Sometimes we would have to adjust the depth of the box.To get the insulation off this wire so that we can get to the conductors inside, the easiest way to avoid cutting yourself or scoring the wire on the inside is to get about 1½ inches of what’s sticking out of the box and just stab into it with a utility knife and cut away from you.

Installing an old work box into an existing wall to add an outlet or wall switch is an easy project that requires just a few common tools that you may already own if you're familiar with basic electrical repairs.

One of the best things is speed control, 30K RPM is just too fast for many applications. The bits just load, overheat and snap. You can also get a 1/4" collet but I wouldn't recommend going over a 1/4" bit, the machine is just too light. Your black wire probably doesn't have a ground. I suggest replacing it entirely rather that fooling around with junction boxes. Maybe cut the existing wire, attach the new wire to each end, and pull the existing wire through the existing boxes until the new wire enters?Drywall Trick- Easiest way for cutting electrical ceiling boxes wall outlets - YouTube. While on a project where the patio ceiling had been blown out during Hurricane Matthew. I wanted.

installing electrical box in plaster

Cutting a Wall Box into Plaster. If existing house wiring is in good condition and an existing circuit has the capacity for an additional outlet, turn off the power, cut a hole in the wall, fish cable to the location, and secure a remodel box (cut-in box) to the finish surface. cutting the holes are easy, you can score with a diamond blade and then just tape with a hammer, or you can just drill a bunch of 1/4" holes around the outline of the box and then finish it off with a few taps from your hammer.

How to Install an Electrical Box in a Finished Wall. Follow these expert tips to install an electrical box into drywall or plaster without the need for wall studs or joists.

I am not sure if they make a bit for Rotozips that will cut OSB, but I know it's the easiest/best way to cut holes in drywall for outlets. It leaves a nice clean opening and its easy to learn how to do. Just wondering if electrical box holes should be cut through the exterior sheathing before or after the siding is on? We used to have them installed before the exterior finish because the electrician would come to do the rough in before the siding was on. Sometimes we would have to adjust the depth of the box.To get the insulation off this wire so that we can get to the conductors inside, the easiest way to avoid cutting yourself or scoring the wire on the inside is to get about 1½ inches of what’s sticking out of the box and just stab into it with a utility knife and cut away from you.

Installing an old work box into an existing wall to add an outlet or wall switch is an easy project that requires just a few common tools that you may already own if you're familiar with basic electrical repairs. One of the best things is speed control, 30K RPM is just too fast for many applications. The bits just load, overheat and snap. You can also get a 1/4" collet but I wouldn't recommend going over a 1/4" bit, the machine is just too light.

installing electrical box in finished wall

free sample cnc precision parts

french blue metal house numbers

how to install electrical boxes

I'm trying to understand the significance of Box 15-16 on the 1099-R form. This is for an in-service after tax 401K distribution to my Roth IRA. No taxes were taken from the .

easiest way to cut existing sheathing for electrical box|how to cut boxes into walls