cnc lathe machine parts ppt It provides details on common G-codes and M-codes used in CNC lathe programming along with examples of cycles for facing, turning, taper turning, grooving and multiple operations. The document provides information on .

Zinc can be welded using both arc welding and gas tungsten arc welding (TIG) processes, but TIG welding is preferred due to heat control. When TIG welding zinc, special precautions must be taken to avoid zinc oxide fumes which are hazardous to human health.

0 · types of lathe machine ppt

1 · threading on lathe machine ppt

2 · milling machine ppt

3 · lathe machining process ppt

4 · lathe machine operations ppt

5 · lathe machine introduction ppt

6 · lathe machine cutting tools ppt

7 · headstock mechanism ppt

Laser Dynamics is a full-service production sheet metal fabrication company located in the heart of West Michigan. Founded in 2000, we've become a trusted partner for many businesses in Grand Rapids and beyond.

Different types of CNC machines such as mills, lathes, and EDM machines are covered. The presentation also discusses CNC programming basics including codes, tool .Common types of CNC machines are CNC lathes for turning cylindrical parts and .It provides details on common G-codes and M-codes used in CNC lathe .CNC machines offer advantages like higher accuracy, reduced lead times, and .

Common types of CNC machines are CNC lathes for turning cylindrical parts and machining centers for milling complex shapes. CNC machines use computer programs and numeric control to operate machine .

It provides details on common G-codes and M-codes used in CNC lathe programming along with examples of cycles for facing, turning, taper turning, grooving and multiple operations. The document provides information on . Describe the main parts of the EMCO CNC turning machine. Operate the EMCO CNC turning machine. Identify the main reference points on the EMCO CNC turning machine.

Different types of CNC machines such as mills, lathes, and EDM machines are covered. The presentation also discusses CNC programming basics including codes, tool paths, and an example programming for a cylindrical part. Common types of CNC machines are CNC lathes for turning cylindrical parts and machining centers for milling complex shapes. CNC machines use computer programs and numeric control to operate machine tools like milling machines and lathes. Key features include automated tool changes and multi-axis movement controlled by motors. It provides details on common G-codes and M-codes used in CNC lathe programming along with examples of cycles for facing, turning, taper turning, grooving and multiple operations. The document provides information on . Describe the main parts of the EMCO CNC turning machine. Operate the EMCO CNC turning machine. Identify the main reference points on the EMCO CNC turning machine.

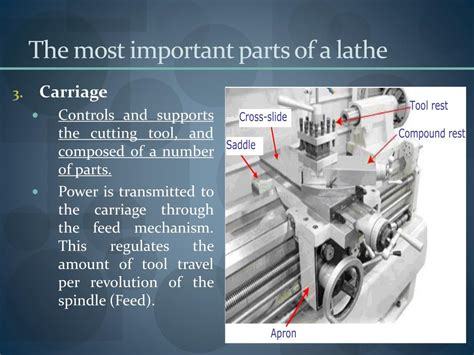

types of lathe machine ppt

CNC Lathe Machines: • Automated version of a manual lathe. • Programmed to change tools automatically. • Used for turning and boring wood, metal and plastic. CNC Milling Machines • Has 3 to 5 axes. • Used for wood, metal and plastic. • Used to make 3D prototypes, moulds, cutting dies, printing plates and signs.Overview We’ll first learn about axis systems. Then we’ll investigate how the machines understand where to move, and the kinds of moves they can make getting there. Machining and CNC Technology by McGraw-Hill Higher Education Identify the various parts and attachments of a lathe and their function. Describe how the cutting tools cut materials. Implement and describe the safety rules for machining using a lathe.

CNC machines offer advantages like higher accuracy, reduced lead times, and increased productivity compared to conventional machine tools. Common types of CNC machines are CNC lathes for turning cylindrical parts and machining centers for milling complex shapes. To kick-start the incorporation of CNC machines courses and programming, you will need necessary and adequately strong machines such as CNC milling machines, CNC lathes, and CNC routers. These machines will provide a solid foundation for your faculty of engineering’s teaching and learning content.By integrating a computer processor, computer numerical control, or “CNC” as it is now known, allows part machining programs to be edited and stored in the computer memory as well as permitting diagnostics and quality control functions during the actual machining. Different types of CNC machines such as mills, lathes, and EDM machines are covered. The presentation also discusses CNC programming basics including codes, tool paths, and an example programming for a cylindrical part.

Common types of CNC machines are CNC lathes for turning cylindrical parts and machining centers for milling complex shapes. CNC machines use computer programs and numeric control to operate machine tools like milling machines and lathes. Key features include automated tool changes and multi-axis movement controlled by motors.

It provides details on common G-codes and M-codes used in CNC lathe programming along with examples of cycles for facing, turning, taper turning, grooving and multiple operations. The document provides information on .

Describe the main parts of the EMCO CNC turning machine. Operate the EMCO CNC turning machine. Identify the main reference points on the EMCO CNC turning machine. CNC Lathe Machines: • Automated version of a manual lathe. • Programmed to change tools automatically. • Used for turning and boring wood, metal and plastic. CNC Milling Machines • Has 3 to 5 axes. • Used for wood, metal and plastic. • Used to make 3D prototypes, moulds, cutting dies, printing plates and signs.

sheet metal math problems

Overview We’ll first learn about axis systems. Then we’ll investigate how the machines understand where to move, and the kinds of moves they can make getting there. Machining and CNC Technology by McGraw-Hill Higher Education Identify the various parts and attachments of a lathe and their function. Describe how the cutting tools cut materials. Implement and describe the safety rules for machining using a lathe. CNC machines offer advantages like higher accuracy, reduced lead times, and increased productivity compared to conventional machine tools. Common types of CNC machines are CNC lathes for turning cylindrical parts and machining centers for milling complex shapes.

sheet metal mechanic tool list

To kick-start the incorporation of CNC machines courses and programming, you will need necessary and adequately strong machines such as CNC milling machines, CNC lathes, and CNC routers. These machines will provide a solid foundation for your faculty of engineering’s teaching and learning content.

threading on lathe machine ppt

milling machine ppt

The 2007 saturn VUE FWD 4 uses a cartridge type oil filter instead of the traditional canister. The location of the oil filter varies, but for your car it is laying horizontally in the front of the engine .

cnc lathe machine parts ppt|milling machine ppt