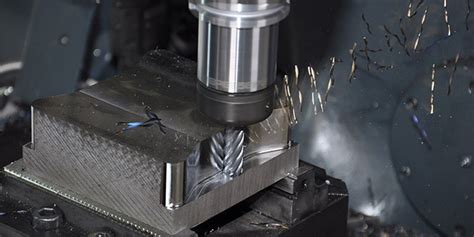

best stainless steel cnc machining parts When machining stainless steel, the right choice of cutting tools is crucial for achieving the best performance and durability. Carbide tools are commonly considered as the most suitable . ZVEX makes effects pedals and amps for guitar and bass and we've been at it since 1995. Our line is a unique blend of no-rules engineering and artistic whim, from our affordable Vexter series to our hand painted and custom designed items.

0 · stainless steel prototype

1 · cnc for stainless steel

2 · 316 stainless steel machinability

3 · 316 ss machinability

4 · 304 vs 316 machinability

5 · 304 stainless steel machinability

6 · 304 stainless machinability

7 · 304 ss machinability

Zone Distribution Enclosures from Belden allow enterprises to take advantage of zone cabling while improving cable management, decreasing costs and enhancing workplace flexibility. Ceiling- or floor-based zone connectivity replaces traditional homeruns to telecom rooms.

stainless steel prototype

Top Stainless Steel Alloys for CNC Machining. Now that we've covered the essential factors to consider, let's explore some of the top stainless steel alloys commonly .

When machining stainless steel, the right choice of cutting tools is crucial for achieving the best performance and durability. Carbide tools are commonly considered as the most suitable .Stainless Steel 304/304L and 316/316L as well as Stainless Steel 303 and Type 360 (17-4) have all proven to be high-quality options for CNC machining projects that require either milling or turning. Check out our material comparison guide . Precision CNC machining stainless steel parts are the choice of industries such as aerospace, automotive, medical and military due to their ideal mechanical properties. Stainless steel has excellent machinability and .

ammo storage metal box stack on

cnc for stainless steel

Many stainless steel items are produced via CNC machining, a versatile manufacturing method that leverages the precision of computer-guided mills, drills, lathes, and other cutting tools to efficiently and cost-effectively create precise, repeatable parts.

Top Stainless Steel Alloys for CNC Machining. Now that we've covered the essential factors to consider, let's explore some of the top stainless steel alloys commonly used in CNC machining: 1. 304 Stainless Steel. Machinability: Excellent; Corrosion Resistance: Good; Strength and Hardness: Moderate; Thermal Properties: FairWhen machining stainless steel, the right choice of cutting tools is crucial for achieving the best performance and durability. Carbide tools are commonly considered as the most suitable option for this application due to their hardness, wear resistance, and .Stainless Steel 304/304L and 316/316L as well as Stainless Steel 303 and Type 360 (17-4) have all proven to be high-quality options for CNC machining projects that require either milling or turning. Check out our material comparison guide for more information. Stainless steel machining doesn’t have to be hard. By identifying the proper material grade for each part, selecting the perfect cutting tool, and optimizing running parameters, headaches from milling steel can become a thing of the past.

Precision CNC machining stainless steel parts are the choice of industries such as aerospace, automotive, medical and military due to their ideal mechanical properties. Stainless steel has excellent machinability and excellent uniformity, as well as good processability and weldability, making it ideal for a variety of CNC machining projects.

Stainless steel CNC machining is an accurate and efficient machining process that uses CNC machines to shape, fabricate and cut stainless steel parts. Numerous industries use stainless steel because it is durable and resistant to corrosion. Generally, though, these are the best stainless steel types and classifications that are used for CNC machining parts and components. Out of these, SUS303 and SUS304 are the most common because of their high-quality properties and the resistance they have.Take your stainless steel part or assembly from print to production with Moon Tool & Die Co. We are an ISO 9001:2015-certified machine shop specializing in the manufacture of high-value components and construction of sophisticated assemblies for demanding environments.

A.R. provides the best stainless steel machined parts available. Visit our site to request a quote today! Many stainless steel items are produced via CNC machining, a versatile manufacturing method that leverages the precision of computer-guided mills, drills, lathes, and other cutting tools to efficiently and cost-effectively create precise, repeatable parts. Top Stainless Steel Alloys for CNC Machining. Now that we've covered the essential factors to consider, let's explore some of the top stainless steel alloys commonly used in CNC machining: 1. 304 Stainless Steel. Machinability: Excellent; Corrosion Resistance: Good; Strength and Hardness: Moderate; Thermal Properties: Fair

american metal fabricators north carolina

When machining stainless steel, the right choice of cutting tools is crucial for achieving the best performance and durability. Carbide tools are commonly considered as the most suitable option for this application due to their hardness, wear resistance, and .

Stainless Steel 304/304L and 316/316L as well as Stainless Steel 303 and Type 360 (17-4) have all proven to be high-quality options for CNC machining projects that require either milling or turning. Check out our material comparison guide for more information.

Stainless steel machining doesn’t have to be hard. By identifying the proper material grade for each part, selecting the perfect cutting tool, and optimizing running parameters, headaches from milling steel can become a thing of the past.

Precision CNC machining stainless steel parts are the choice of industries such as aerospace, automotive, medical and military due to their ideal mechanical properties. Stainless steel has excellent machinability and excellent uniformity, as well as good processability and weldability, making it ideal for a variety of CNC machining projects. Stainless steel CNC machining is an accurate and efficient machining process that uses CNC machines to shape, fabricate and cut stainless steel parts. Numerous industries use stainless steel because it is durable and resistant to corrosion. Generally, though, these are the best stainless steel types and classifications that are used for CNC machining parts and components. Out of these, SUS303 and SUS304 are the most common because of their high-quality properties and the resistance they have.Take your stainless steel part or assembly from print to production with Moon Tool & Die Co. We are an ISO 9001:2015-certified machine shop specializing in the manufacture of high-value components and construction of sophisticated assemblies for demanding environments.

316 stainless steel machinability

JetSki Solutions can remanufacture your 900 or 1100 ebox and convert to Zeeltronic Programmable CDI. Significant power gains !

best stainless steel cnc machining parts|304 ss machinability