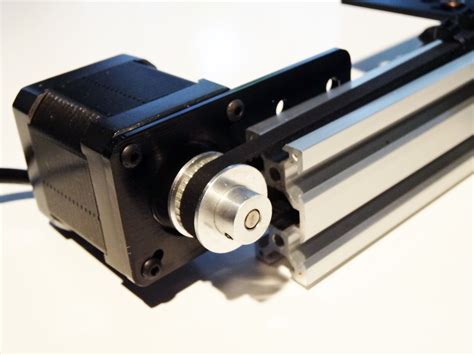

actuators used in cnc machine A rack and pinion is a type of linear actuator consisting of a circular gear (the pinion) that engages with a linear gear (the rack) to convert . Wall ovens are usually very specific where the junction box needs to be and it can vary greatly. For example one type may want the box in the top right or left of the opening. Others may want the whip running through the bottom support shelf.

0 · linear actuators for cnc machines

1 · examples of linear actuators

In the back of a metal junction box will be a "nub" which is threaded for a 10-32 screw. This is for a ground wire. I suppose that what you have found by the two really good answers is that the term "sockets" and "outlets" are not very definitive.Typical coverplate screws are 6-32. Answers based on the National Electrical Code. Local amendments may apply. Check with your local building officials. If the box is a .

Selecting the appropriate linear actuator for a CNC machine requires careful consideration of various factors. Some key considerations include load capacity, speed, stroke length, precision requirements, space constraints, and budget.Actuator selection of CNC machine tool based in dynamical modeling and control Abstract: CNC (Computer Numerical Control) machine tools are devices of high precision milling largely .Actuators are integral to manufacturing and automation systems, where they enable precise control of machinery and processes. Examples include: Robotic Arms: Use electric actuators . A rack and pinion is a type of linear actuator consisting of a circular gear (the pinion) that engages with a linear gear (the rack) to convert .

Actuators and stages are critical components in automation and precision engineering, used to convert energy into controlled motion. Linear actuators provide straight-line movement, while .

NSK’s AXIS series offers the best linear actuator solutions tailored to various industries and applications, including: CNC Manufacturing Ideal for precision tasks like plastic assembly like .applications that require precise position control such as camera motion rigs. An actuator is any electromechanical device that can convert electrical signals to physical movement. Actuators . Although there has been extensive research in tool actuator design and control for ultra-precision diamond turning, few researchers have addressed the use of piezo-based fast .In this article, Circuitrocks will make sense of what an actuator is, the way actuators work and the job of actuators in CNC-driven mechanical technology.

Selecting the appropriate linear actuator for a CNC machine requires careful consideration of various factors. Some key considerations include load capacity, speed, stroke length, precision requirements, space constraints, and budget.Actuator selection of CNC machine tool based in dynamical modeling and control Abstract: CNC (Computer Numerical Control) machine tools are devices of high precision milling largely employed due to their high precision and to allow simultaneous positioning and velocity control of each machine's axis.Actuators are integral to manufacturing and automation systems, where they enable precise control of machinery and processes. Examples include: Robotic Arms: Use electric actuators to perform tasks such as welding, painting, and assembly. CNC Machines: Use linear actuators to control the movement of cutting tools with high precision. A rack and pinion is a type of linear actuator consisting of a circular gear (the pinion) that engages with a linear gear (the rack) to convert rotational motion into linear motion. Rack and pinion drives are commonly used in CNC machines, such as .

cnc machine tool monitoring software

CNC machines, which are pivotal in modern manufacturing, use actuators to achieve precise cuts, drills, and other operations. The linear movement provided by these actuators, often driven by a lead screw, ensures that products are .Actuators and stages are critical components in automation and precision engineering, used to convert energy into controlled motion. Linear actuators provide straight-line movement, while rotary actuators enable rotational motion.NSK’s AXIS series offers the best linear actuator solutions tailored to various industries and applications, including: CNC Manufacturing Ideal for precision tasks like plastic assembly like CNC laser plastic welding with 2-Axis, XY configuration using ball screw or linear motor drive.

applications that require precise position control such as camera motion rigs. An actuator is any electromechanical device that can convert electrical signals to physical movement. Actuators used in CNC machines include stepper motors, hydraulic actuators and servo motors. CNC machines are normally controlled in a format known as G-code. Although there has been extensive research in tool actuator design and control for ultra-precision diamond turning, few researchers have addressed the use of piezo-based fast tool servos for precision shaft machining on conventional CNC turning machines.In this article, Circuitrocks will make sense of what an actuator is, the way actuators work and the job of actuators in CNC-driven mechanical technology.

Selecting the appropriate linear actuator for a CNC machine requires careful consideration of various factors. Some key considerations include load capacity, speed, stroke length, precision requirements, space constraints, and budget.

Actuator selection of CNC machine tool based in dynamical modeling and control Abstract: CNC (Computer Numerical Control) machine tools are devices of high precision milling largely employed due to their high precision and to allow simultaneous positioning and velocity control of each machine's axis.Actuators are integral to manufacturing and automation systems, where they enable precise control of machinery and processes. Examples include: Robotic Arms: Use electric actuators to perform tasks such as welding, painting, and assembly. CNC Machines: Use linear actuators to control the movement of cutting tools with high precision. A rack and pinion is a type of linear actuator consisting of a circular gear (the pinion) that engages with a linear gear (the rack) to convert rotational motion into linear motion. Rack and pinion drives are commonly used in CNC machines, such as . CNC machines, which are pivotal in modern manufacturing, use actuators to achieve precise cuts, drills, and other operations. The linear movement provided by these actuators, often driven by a lead screw, ensures that products are .

Actuators and stages are critical components in automation and precision engineering, used to convert energy into controlled motion. Linear actuators provide straight-line movement, while rotary actuators enable rotational motion.NSK’s AXIS series offers the best linear actuator solutions tailored to various industries and applications, including: CNC Manufacturing Ideal for precision tasks like plastic assembly like CNC laser plastic welding with 2-Axis, XY configuration using ball screw or linear motor drive.applications that require precise position control such as camera motion rigs. An actuator is any electromechanical device that can convert electrical signals to physical movement. Actuators used in CNC machines include stepper motors, hydraulic actuators and servo motors. CNC machines are normally controlled in a format known as G-code.

linear actuators for cnc machines

examples of linear actuators

Although there has been extensive research in tool actuator design and control for ultra-precision diamond turning, few researchers have addressed the use of piezo-based fast tool servos for precision shaft machining on conventional CNC turning machines.

cnc machine tool repair houston texas

The specific screw size that is required will be specified in the installation instructions for the electrical box. Junction boxes are typically secured with 6 screws. 6 screws .

actuators used in cnc machine|linear actuators for cnc machines