cnc metal sheet design Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs. Geomiq’s digital manufacturing platform makes rapid prototype and production manufacturing .

ISCP - Makers of Vaultz, Snap-N-Store and Find It Shoplet flipcost IPC-STORE Corebuy The Factory Depot SIM Supply, Inc. Clear all . Plastic. 4.4 out of 5 stars. 1,025. 100+ bought in past month. $24.47 $ 24. 47. FREE delivery Fri, Aug 30 on $35 of items shipped by Amazon. Only 20 left in stock - order soon.

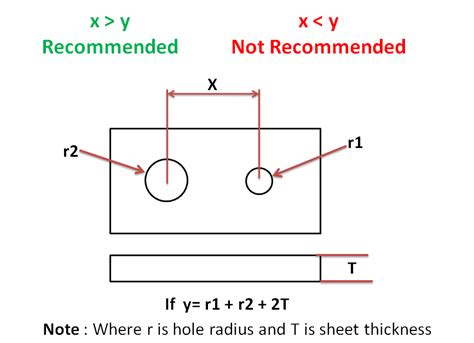

0 · hole to distance sheet metal

1 · cnc sheet metal folding machine

2 · cnc sheet metal cutting machine

3 · cnc sheet metal bending machine

4 · cnc machine for steel cutting

5 · cnc cutting machine for metal

6 · best metal sheet cutter manufacturers

7 · affordable cnc machines for metal

To request more information about Vamco Sheet Metal Inc from abroad please call the international phone number +1.845.265.4563 under which you will be able to speak with Owner August Vettorino or be directed to the appropriate contact person.

CNC Precision Unveiled: At its core, CNC sheet metal folding involves the use of computer-controlled machines to bend flat metal sheets at desired angles, creating intricate forms and shapes. Bend relief notch 4. A consistent bend orientation is important for ease of fabrication.. 5. The K-factor of your bending design should be chosen from a K-factor chart .

Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending.Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with .

Sheet metal design is the process of engineering sheet metal into equipment, parts, assemblies, and products. Autodesk Fusion provides the necessary software to automate sheet metal design, nest your components, and create .Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs. Geomiq’s digital manufacturing platform makes rapid prototype and production manufacturing .

Discover the art of transforming flat metal sheets into intricate forms with unparalleled accuracy through CNC sheet metal folding. Learn techniques, benefits, and tips in this comprehensive guide.CNC (Computer Numerical Control) machines revolutionize how sheet metal is fabricated by offering precision, efficiency, and repeatability. Here are some of the most common types used in the industry: CNC Laser Cutters: These .

In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your .

CNC Precision Unveiled: At its core, CNC sheet metal folding involves the use of computer-controlled machines to bend flat metal sheets at desired angles, creating intricate forms and shapes. Bend relief notch 4. A consistent bend orientation is important for ease of fabrication.. 5. The K-factor of your bending design should be chosen from a K-factor chart based on the material type, bend angle, and operation. It typically ranges from 0.25 to 0.50. 6. If your design has offset bends ( Z-shaped), Maintain flange length (on Both Sides)= 3 x thickness(t) Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending.Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting.

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments.

parraghi roofing & sheet metal llc

hole to distance sheet metal

Sheet metal design is the process of engineering sheet metal into equipment, parts, assemblies, and products. Autodesk Fusion provides the necessary software to automate sheet metal design, nest your components, and create tool paths for CNC.Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs. Geomiq’s digital manufacturing platform makes rapid prototype and production manufacturing easy.

Discover the art of transforming flat metal sheets into intricate forms with unparalleled accuracy through CNC sheet metal folding. Learn techniques, benefits, and tips in this comprehensive guide.CNC (Computer Numerical Control) machines revolutionize how sheet metal is fabricated by offering precision, efficiency, and repeatability. Here are some of the most common types used in the industry: CNC Laser Cutters: These machines use a high-powered laser beam to make precise cuts in sheet metal. Ideal for intricate designs and fine details.In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your designs for computer numerical control (CNC) machining.

CNC Precision Unveiled: At its core, CNC sheet metal folding involves the use of computer-controlled machines to bend flat metal sheets at desired angles, creating intricate forms and shapes.

Bend relief notch 4. A consistent bend orientation is important for ease of fabrication.. 5. The K-factor of your bending design should be chosen from a K-factor chart based on the material type, bend angle, and operation. It typically ranges from 0.25 to 0.50. 6. If your design has offset bends ( Z-shaped), Maintain flange length (on Both Sides)= 3 x thickness(t) Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending.Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting.

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments.Sheet metal design is the process of engineering sheet metal into equipment, parts, assemblies, and products. Autodesk Fusion provides the necessary software to automate sheet metal design, nest your components, and create tool paths for CNC.

Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs. Geomiq’s digital manufacturing platform makes rapid prototype and production manufacturing easy.

Discover the art of transforming flat metal sheets into intricate forms with unparalleled accuracy through CNC sheet metal folding. Learn techniques, benefits, and tips in this comprehensive guide.CNC (Computer Numerical Control) machines revolutionize how sheet metal is fabricated by offering precision, efficiency, and repeatability. Here are some of the most common types used in the industry: CNC Laser Cutters: These machines use a high-powered laser beam to make precise cuts in sheet metal. Ideal for intricate designs and fine details.

cnc sheet metal folding machine

partes de la soldadura mig

Another alternative to using glue to attach fabric to metal is using Velcro adhesive tapes. Velcro is a popular brand of hook-and-loop fasteners, which is a convenient and easy-to-use option for attaching fabric to metal. The hooks and loops interlock with each other, providing a secure grip and can be easily detached without damaging the fabric.

cnc metal sheet design|best metal sheet cutter manufacturers