classification of sheet metal forming processes What shape have we created? Steel versus aluminum. 3. We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to . The MasterLok-90 and MasterLok-FS systems feature trapezoidal panels for metal roofing projects with slopes as low as 1/4:12. Learn more.

0 · sheet metal manufacturing process

1 · sheet metal forming techniques

2 · sheet metal forming process

3 · sheet metal forming

4 · sheet forming process

5 · metal forming process specifications

6 · metal forming process pdf

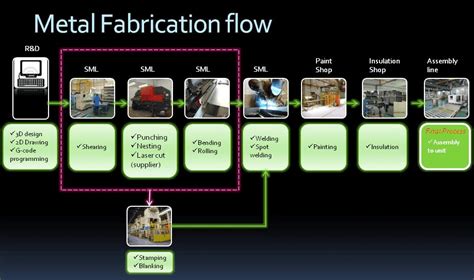

7 · metal forming process diagram

Tri-County Roofing & Sheet Metal also honors manufacturer warranties and .

Sheet forming: Sheet metal forming involves forming and cutting operations performed on metal sheets, strips, and coils. The surface area-to-volume ratio of the starting metal is relatively .Fig. 1.3.1: Classification of metal forming processes Typically, metal forming processes can be classified into two broad groups. One is bulk forming and the other is sheet metal forming. Bulk . Due to wide range of applications, the process of forming the sheet metal into various shapes leads to classification of the forming processes based on specific operation. .

This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal .

What shape have we created? Steel versus aluminum. 3. We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to . Sheet metal forming involves the application of tensile and shears forces to fabricate sheets, plates, and strips to a desired possible shape using a set of tools. The punch and die are used as tools in the fabrication process. Metal forming processes are classified based on the type of force applied during the deformation. Here are the main categories: In compress stress forming process the metal is compressed to change shape typically involve .

Sheet Metal Classification . There are 3 major classes of processes of sheet metal working. Cutting: Cutting is the use of shearing forces to remove material from a work piece. Technically not a metal forming process, but of extreme .In this article we will discuss about the classification of metal forming processes. 1. Compressive Forming Processes: In these processes the plastic state is reached by application of uni-axial .Classification of forming: Typically, metal forming processes can be classified into two broad groups. Bulk Forming Processes – One is bulk-forming and the other is sheet metal forming. Bulk deformation refers to the use of raw materials for forming which .Sheet forming: Sheet metal forming involves forming and cutting operations performed on metal sheets, strips, and coils. The surface area-to-volume ratio of the starting metal is relatively high. Tools include punch, die that are used to deform the sheets. Classification of basic sheet forming processes Bending Deep drawing shearing

Fig. 1.3.1: Classification of metal forming processes Typically, metal forming processes can be classified into two broad groups. One is bulk forming and the other is sheet metal forming. Bulk deformation refers to the use of raw materials for forming which have low surface area to volume ratio. Rolling, forging, extrusion and drawing are bulk .

sheet metal manufacturing process

Due to wide range of applications, the process of forming the sheet metal into various shapes leads to classification of the forming processes based on specific operation. This classification involves bending, blanking, stretch forming and deep drawing.This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal forming, sheet-metal forming, and sheet-bulk-metal forming.

deep wall electrical box

What shape have we created? Steel versus aluminum. 3. We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to “bendover.” Note from M=0 to M=MY the curve is linear. Where εY is the strain at yield. Also since the strain at y Y is -εY, we can write. ( !" − 4 R $ ! Sheet metal forming involves the application of tensile and shears forces to fabricate sheets, plates, and strips to a desired possible shape using a set of tools. The punch and die are used as tools in the fabrication process. Metal forming processes are classified based on the type of force applied during the deformation. Here are the main categories: In compress stress forming process the metal is compressed to change shape typically involve reduced thickness or increased density.

Sheet Metal Classification . There are 3 major classes of processes of sheet metal working. Cutting: Cutting is the use of shearing forces to remove material from a work piece. Technically not a metal forming process, but of extreme industrial importance. Bending: Bending is the forming of a sheet metal work about an axis.In this article we will discuss about the classification of metal forming processes. 1. Compressive Forming Processes: In these processes the plastic state is reached by application of uni-axial or multi-axial compressive forces.Classification of forming: Typically, metal forming processes can be classified into two broad groups. Bulk Forming Processes – One is bulk-forming and the other is sheet metal forming. Bulk deformation refers to the use of raw materials for forming which .

sheet metal forming techniques

Sheet forming: Sheet metal forming involves forming and cutting operations performed on metal sheets, strips, and coils. The surface area-to-volume ratio of the starting metal is relatively high. Tools include punch, die that are used to deform the sheets. Classification of basic sheet forming processes Bending Deep drawing shearingFig. 1.3.1: Classification of metal forming processes Typically, metal forming processes can be classified into two broad groups. One is bulk forming and the other is sheet metal forming. Bulk deformation refers to the use of raw materials for forming which have low surface area to volume ratio. Rolling, forging, extrusion and drawing are bulk .

Due to wide range of applications, the process of forming the sheet metal into various shapes leads to classification of the forming processes based on specific operation. This classification involves bending, blanking, stretch forming and deep drawing.This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal forming, sheet-metal forming, and sheet-bulk-metal forming.

What shape have we created? Steel versus aluminum. 3. We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to “bendover.” Note from M=0 to M=MY the curve is linear. Where εY is the strain at yield. Also since the strain at y Y is -εY, we can write. ( !" − 4 R $ !

Sheet metal forming involves the application of tensile and shears forces to fabricate sheets, plates, and strips to a desired possible shape using a set of tools. The punch and die are used as tools in the fabrication process. Metal forming processes are classified based on the type of force applied during the deformation. Here are the main categories: In compress stress forming process the metal is compressed to change shape typically involve reduced thickness or increased density.

Sheet Metal Classification . There are 3 major classes of processes of sheet metal working. Cutting: Cutting is the use of shearing forces to remove material from a work piece. Technically not a metal forming process, but of extreme industrial importance. Bending: Bending is the forming of a sheet metal work about an axis.

sheet metal forming process

decorative stainless steel sheet metal

deep electrical box dimensions

Whether you’re safeguarding valuable equipment, trash containers, or dumpsters, these gates serve as formidable barriers that offer peace of mind. The adjustable frames, a hallmark feature, add a layer of flexibility, allowing for hassle-free resizing during installation to achieve a precise fit.

classification of sheet metal forming processes|metal forming process specifications