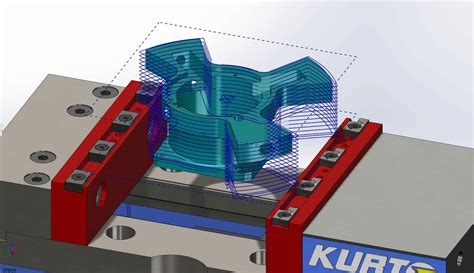

solidworks for cnc machining SOLIDWORKS CAM Standard lets you quickly program individual milled parts and configurations without leaving the SOLIDWORKS 3D CAD environment. You have full access to defining rules within SOLIDWORKS CAM to create and build to your company standards, as well as . Wiska A.C.E Combi Kit with earth bar for armoured cable earthing. Quick and effective termination for SWA cables with no drilling to the enclosure and still maintaining IP rating of the enclosure.

0 · solidworks for cnc milling

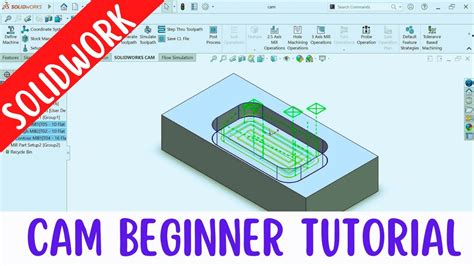

1 · solidworks cam tutorial for beginners

2 · solidworks cam setup sheet

3 · solidworks cam machine setup

4 · how to open solidworks cam

5 · generate g code from solidworks

6 · cnc programming with solidworks cam

7 · cnc machine design by solidworks

$14.99

SOLIDWORKS CAM Standard lets you quickly program individual milled parts and configurations without leaving the SOLIDWORKS 3D CAD environment. You have full access to defining rules within SOLIDWORKS CAM to create and build to your company standards, as well as .Contact Sales for SOLIDWORKS . SOLIDWORKS® products are easy to .

DIY CNC software helps you develop your ideas and discover these benefits: .Learn about NC Shop Floor Programmer, a new browser-based role in our .Did you know that SOLIDWORKS CAM can handle about 80% of your day-to-day .

DIY CNC software helps you develop your ideas and discover these benefits: Speed: You can use CNC hobby software to build parts, prototypes, and products much faster. CAD software can help you model your design, export data, and . SOLIDWORKS CAM comes with an included list for some of the more standard machines (like the Haas VF-3 I used to create my program) but custom post processors can be written by TriMech to let you use . In this video, we take a look at the step by step process to generate your first CNC code using SOLIDWORKS CAM or CAMWorks. We cover the basic layout of the user interface, setting up the. SOLIDWORKS CAM is a Computer Aided Manufacturing add-in for SOLIDWORKS that allows us to create G/M code for CNC machining our .

Using SOLIDWORKS CAM to program an LS1 engine valley cover. Learn more about SOLIDWORKS CAM: https://hawkridgesys.com/solidworks/camDownload link -https://ha.MicroEstimating software combines manufacturing knowledge with process engineering and costing formulas to produce precise estimates. It incorporates Feature Recognition Technology, using SOLIDWORKS for interpolated 3D .

SOLIDWORKS CAM is a Computer Aided Manufacturing add-in for SOLIDWORKS that allows us to create G/M code for CNC machining our parts.. What is special about SOLIDWORKS CAM is that it uses Knowledge Based .Hello, I've been trying to use shop floor machining to get some g code for my milling CNC machine. From my understanding my machine takes GRBL g code but I am completely unable to figure out how to get the shop floor control software to output g code that my machine can understand? . My other problem is is that all of the references are to .The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download! . Machine design Marine Medical Military Miscellaneous Nature Piping Robotics Speedrun Sport Tech Tools Toys .

NC Shop Floor Programmer is a powerful role in the 3DEXPERIENCE® Works portfolio that enables NC programmers to create and validate 2.5- and 3-axis NC programs, generate wire EDM operations, and verify possible issues during production with machine simulation.You can store and access your data on the 3DEXPERIENCE platform, and quickly search for and find .CNC Compensation for Curve Features: Corner Slowdown and Arc Feed Rate: . Search 'Improved Chamfer Machining' in the SOLIDWORKS Knowledge Base. . Content Version: 2019 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help.

One of the main benefits of this role is that you can validate your NC programs with machine simulation, detecting issues digitally before you make your first physical cut, and saving you lots of time and, of course, money. . Tags: 3DEXPERIENCE SOLIDWORKS for Makers, cnc, makers, manufacturing, NC Shop Floor Progammer. Using SOLIDWORKS CAM to program an LS1 engine valley cover. Learn more about SOLIDWORKS CAM: https://hawkridgesys.com/solidworks/camDownload link -https://ha.3DEXPERIENCE SOLIDWORKS for Makers USD USD/year (Apply Code: BLACKFRIDAY50%OFF) Proven and powerful SOLIDWORKS 3D CAD Features include: 3D CAD: Locally Installed; Local & Cloud Storage; Photorealistic Rendering; 2.5 & 3-Axis CAM; Access to Learning Content and Maker Communities; Devices Supported: Windows PC .

solidworks for cnc milling

The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download! . Machine design Marine Medical Military Miscellaneous Nature Piping Robotics Speedrun Sport Tech Tools Toys .What I had to do for my hobby CNC is just guess and check. My machine uses gcode, but I don't think it will be different for you. Save the post, load it into the machine, and see if everything looks right on the tool paths simulator. I am assuming your CNC has control software that will show you the tool paths before you start cutting.

superior metal fabricators riverside ca

SOLIDWORKS CAM. SolidWorks CAM: Finding Machining Time . 4002 views February 10, 2021 0. You are able to find out the total machining time required for your CAM programs. Given that the feeds and speeds of your specific machine has been properly setup, the machining time will reflect fairly accurately in the real world.ONGAA CAM is an add-in that allows the user to add CNC machining to SOLIDWORKS model. The add-in then generates machine files. By applying machining in SOLIDWORKS, the model can be altered, resized, or features added/suppressed and the geometry will be accurately reflected in new machining files.

Computer numerical control (CNC) machining is a manufacturing process. It relies on code to control the movement of tools, such as lathes, router bits, and milling bits, found in CNC machines, to produce parts with certain designed features.However, you have to accomplish several tasks before using these crucial machines and their built-in tools.ALL posts related to SOLIDWORKS are welcome. . Manufacturing Hi, it's been surprisingly hard to find any answers or information on how to locate total machining time or even total length of tool path from SOLDIWORKS CAM. . Looking to adjust feed and speeds to find cheapest possible manufacturing method or decide which CNC machine is optimal .Our labs are equipped with state-of-the-art computers, CAD / CAM software, and multiple CNC milling and turning machining centers. The Manufacturing Technology curriculum provides training in both conventional machining processes as well as digital machining processes, including CAD and CAM classes. SolidWorks switching dimension formats in cut list? Thread starter i_r_machinist; Start date Aug 8, 2019; Replies 3 Views 3,530 I. i_r_machinist Titanium. Joined Apr 12, 2007 Location Dublin Texas. . CNC Machining. ABOUT PRACTICAL MACHINIST.

SolidWorks’ .sldprt and .sldasm files are widely used in CNC machining for their ease of use and ability to handle complex geometries. The parametric design capabilities in SolidWorks make it an ideal choice for manufacturers aiming to produce high-precision parts. In this video you will learn how to setup cnc machine using solidworks. I will describe some basic functions of solidworks HSM express to make gcode for cnc . Made by Inventables, makers of the popular X-Carve CNC router, Easel is sold as the easiest and most beginner-friendly CAD-CAM software for CNC around. It’s also a CNC control software. So, even if you’re not using Easel’s CAD/CAM, It’s easy to import g-codes from tools like Fusion 360 into Easel and get machining right away for a convenient workflow. SOLIDWORKS CAM delivers fully integrated, knowledge-based CNC programming right inside SOLIDWORKS.SOLIDWORKS CAM generates machining information fast. Using .

VisualMILL for SOLIDWORKS is one of the CNC machining industry's most affordable integrated CAM software for SOLIDWORKS, allowing the NC programming of SOLIDWORKS models utilizing 2-1/2, 3, 4, and 5 axis machining methods. It helps you to detect machine axis limit errors, tool reachability problems, and create simulation time charts. You can also review your numerical control (NC) toolpath functionality by viewing a simulation of the machining process to validate your NC programs and make sure the simulation matches your manufacturing intentions. Machine Simulation

In this video, we take a look at the step by step process to generate your first CNC code using SOLIDWORKS CAM or CAMWorks. We cover the basic layout of the .

CNC machining from solidworks. MC By Matt Conlin 01/08/07. Do CNC machines use a type of program that is compatible with solidworks? So if I draw a model, will a cnc machine be able to understand the program/file? comments: 0. View or Reply . . Overall, using Solidworks in CNC machining can help in improving the accuracy, efficiency, and quality of the final product. In conclusion, transferring Solidworks parts to CNC machines can seem like a daunting task, but it doesn’t have to be. With the right tools and techniques, you can easily transfer your designs to the CNC machine for .

solidworks cam tutorial for beginners

If changes to the post processor are required, please contact your SOLIDWORKS CAM reseller for customization services. The post processors in the library for CNC mills are for 3 axis machining and several also include 4 & 5 axis indexing (or pre-positioning) for 3+2 machining using SOLIDWORKS CAM Pro. Post processors for CNC lathes (turning .

solidworks cam setup sheet

Short updated that we enabled big junction boxes in ROW production, we now support up to 5KM. Now they are available in All Production environments. by abc1357 Sun .

solidworks for cnc machining|cnc programming with solidworks cam