how to build your own cnc machine part 3 This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I . RHEINZINK is the world’s leading architectural zinc manufacturer for roofs, wall cladding and roof drainage. Sustainable, aesthetic, crafted, and versatile – RHEINZINK inspires architectural ideas. Architectural zinc from RHEINZINK is the definition of sustainable building.

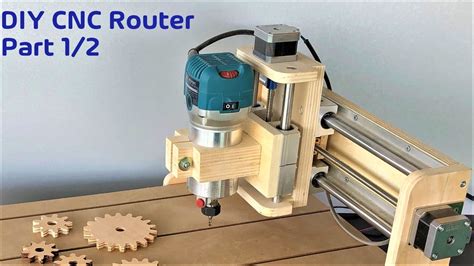

0 · homemade cnc router machine

1 · homemade cnc milling machine plans

2 · homemade cnc machine plans

3 · homemade cnc machine

4 · home built cnc milling machine

5 · do it yourself cnc machine

6 · diy cnc machine for woodworking

7 · build it yourself cnc router

Inspired by the Box of Metal, one of the heaviest-sounding pedals in the ZVEX lineup. This board will punch your audience with a massive wave of distortion with a great thump and excellent .

Today we complete our unholy marriage of cutting boards and dot matrix printers in Part 3 of How-To: Build your own CNC machine. Good luck. Back in Part 1, we introduced the. DIY CNC Router/Machine: How to Build Your Own. by Andreas Giencke. Updated Feb 6, 2023. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to .This instructable shows all the steps I went through in designing and building this CNC router. The main thing I like about a CNC router, is that it is so versatile. .

white barn house metal

This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I . Learn how to build your very own CNC machine with this ultimate guide for makers! This step-by-step tutorial covers everything you need to know, from choosin. How to Build Your Own CNC Machine From Scratch. Image Credits: buildyourcnc.com. When building your own CNC machine, you must first figure out what type of CNC machine you want to create. This way, it will be . Whether you want to launch your own business, replace hard-to-find parts, or simply create custom products that aren’t available anywhere else, you can do it with a CNC machine. And where better to start as a maker than .

So I’ve spent a lot of time writing a complete end-to-end guide how to build your own CNC-machine using 3d-printed and off-the-shelf parts. It includes detailed explanations (text and images) of every step, a complete bill of materials (with .

Most of the cut face is fairly smooth. There's a bit of tearing at the top because the bit is cutting upwards (in order to clear the chips). The top face of the left-over wood has marks where he's shaved a thin layer off to level it. Linear slides are key to the design of a functional machine. These slides are a half successful experiment. We used 1/4-inch steel rod from the hardware store and some brass and steel bushings.Teaches you to design and mill your very own wooden and aluminum parts, toys, gadgets—whatever you can dream up ; Similar content being viewed by others. . including LEGO robotics, open source software, and building your own CNC machine as well as a 3D printer. He is the editor-in-chief of the number one MINDSTORMS NXT blog, The NXT Step .

The 8020 CNC machine is a type of CNC router that uses extruded aluminum profiles from a company called 80/20 Inc. This company specializes in providing modular framing systems that can be used to build anything from basic workbenches to complete automation systems. To build your own 8020 CNC machine, you'll need to start with the right components. Then they go on to show you how to use it, how to document your designs in computer-aided design (CAD) programs, and how to output your designs as specifications and tool paths that feed into the CNC machine, controlling it as it builds whatever parts your imagination can dream up.Don't be intimidated by abbreviations like CNC and terms like . Building your own CNC machine can be an exciting and rewarding project. With the right knowledge and resources, you can create a customized CNC machine right in your own home. . Purchase the necessary parts and tools for your DIY CNC machine. This may include stepper motors, linear slides, spindle, controller board, and other components. Make . 5. What skill sets should you have to build a CNC machine? It’s easier to build your own CNC machine if you already have some of the necessary skills. As such, aim to complete a project that plays to your experience. If you’re already experienced in woodworking or metalworking, then you may wish to try out a more challenging project.

In this blog post, we will guide you through the step-by-step process of building your own CNC machine, from sourcing materials to programming the machine. Chapter 1: Understanding CNC Machines . Introduction to CNC machines . Advantages of building a DIY CNC machine . Basic components of a CNC machine . Chapter 2: Planning and Design

Assemble the parts carefully, following the manufacturer's instructions, and enjoy the satisfaction of watching your DIY CNC machine come to life. Remember, building a CNC machine requires patience, precision, and attention to detail. It's a challenging but rewarding project that allows you to unlock a world of possibilities in your own . Build Your Own CNC Machine (Technology in Action) [Hood-Daniel, Patrick, Kelly, James Floyd] on Amazon.com. *FREE* shipping on qualifying offers. . When I had the machine build I was able to make parts and cut stuff completely with open source software. Linux EMC2, PyCAM, and HeeksCAD. Regardless, my machine works. It really really really . Find out more about CNC router parts and get some guidance to join the fun. All3DP; All3DP Pro; Printables Basics Buyer's Guides News Formnext 2024. More . Printables; . DIY CNC Router: Which Parts Do You Need to Build Your Own? by Che Simons, Andreas Giencke Published Sep 21, 2024

Resin Printer Parts Stepper Motors CNC Controllers Motion Electronics Wire and Cable . CNC Book "Build Your Own CNC Machine" The book on how to build yourself a CNC machine from the ground-up, is available. The book was authored by James Floyd Kelly (a great friend and writer of many tech books) and Patrick Hood-Daniel (the author of this .

Additionally, we'll suggest some budget-friendly alternatives that won't compromise the functionality of your machine. Section 3: Designing Your CNC Machine . In this section, we'll discuss different design considerations for your wood CNC machine. We'll cover topics such as machine size, frame materials, overall stability, and dust collection .By constantly exploring new features and techniques, your CNC machine can evolve along with your skills and project requirements. 7. Conclusion . Building your own CNC machine is a challenging but rewarding endeavor. With the right CNC kit and proper guidance, you can bring your creative ideas to life with precision and accuracy.

Cautions. Whether you are building an affordable CNC router, or making the best budget CNC lathe machine, even working with DIY the cheapest CNC milling machine, the first caution is the power supply of the CNC . In that matter, a lot of people that own their CNC machines choose to make car parts for themselves. However, you will need proper resources, like materials and equipment that are necessary for a particular part of the vehicle. .Get full access to Build Your Own CNC Machine and 60K+ other titles, with a free 10-day trial of O'Reilly. There are also live events, courses curated by job role, and more. Start your free trial. . controlling it as it builds whatever parts your imagination can dream up. Free Book Build Your Own CNC Machine First Edition By Patrick Hood-Daniel and James Floyd Kelly pdf. . Do you want to manufacture your parts? Build Your Own CNC Machine is a book to start with. Patrick Hood Daniel, a CNC expert and best-selling author, James Kelly, collaborates to illustrate how to create your own CNC machine. .

This also might be a good place for the various types of CNC machines.- Chapter 2 DIY-CNC Project Overview Description of the project, tools required and safety. Will include computer requirements.- Chapter 3 Cutting the parts describes the parts layout and special instructions for cutting.- Special instructions for labeling parts for use in . Dive into the world of CNC and transform your ideas into reality with precision and efficiency. Start building your own CNC machine today and unlock limitless creative potential. 1. Introduction to CNC Machines. What is CNC? CNC stands for Computer Numerical Control, a technology used to automate the control of machine tools. You probably won’t believe this, but the CNC machine described in this book can be built with a total of four tools (mitre box, mitre saw, tap, and electric drill/screwdriver) and a few .The first thing I'd say is that if your time is worth anything and your only goal is to have a working machine, just buy one. That said, I build because I enjoy it. To me the build process is part of the hobby. My first build was optimised for full sheets of plywood. So minimum work size of 2400x1400mm but a very small Z axis: 100mm.

whhite steel storage cabinet recessed handle

Plus they’re good machines for the price and there’s a ton of help on that Facebook group and from the manufacturer. I’m not against building your own machine, I just think by the time you’ve got through all the learning curves, bought the standard parts, had someone make the oddball stuff, etc. you’ll wish you’d just bought a kit. Build instructions for an offline CNC controller based on the 4 axis DDCS V3.1 controller, part 2. Wiring diagrams and parameter settings for the controller .Search for proper parts and take your time. I could have build the machine in a month, but because I had to search for parts on Ebay etc., it took me half a year. This keeps the costs down of course, I was able to build the machine for less then €1000,-I hope the story encourages you to build your own CNC milling machine. Volume 5, Issue 11, Part 3, 2018, Pages 24404-24413. A Build-Your-Own Three Axis CNC PCB Milling Machine. Author links open overlay panel N. Sathyakumar, . Keywords: Build your own technology; CNC PCB machine; PCB manufacturing; Auto-levelling; Open source hardware and software. 1. Introduction d in sem und 27 ore, the ndia to the pro pro .

The best part about building your own CNC machine is that it’s relatively easy to do so using off-the-shelf components and the open source Arduino platform. This guide will walk you through all the essential steps necessary to build your very own Arduino-based CNC drawing machine. Gather the Necessary Materials

homemade cnc router machine

white and silver metallic fabric

homemade cnc milling machine plans

homemade cnc machine plans

HASSLE & HEADACHE FREE - The Quick Lock Metal Smart Box Spring comes together with easy-to-follow instructions, fewer bolts and absolutely no headaches; assembly that’s intuitive and packaging that seems to defy the laws of physics - now that’s what we call a new-age box spring

how to build your own cnc machine part 3|homemade cnc machine plans