copper cnc machine You can efficiently machine copper alloys with various methods, including CNC copper milling. This automated process employs computerized controls to manage multi-point rotary cutting tools. As these tools rotate and traverse the .

View Welder I salary data across 492 cities in Kennewick, WA. Get a free salary report tailored by income, experience, and education.

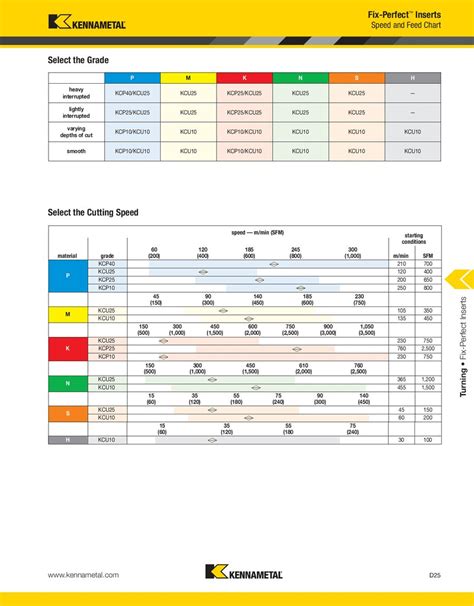

0 · turning copper speeds and feeds

1 · speeds and feeds for copper

2 · machinability of copper 110

3 · end mills for copper

4 · cutting speed for copper milling

5 · copper segregation procedure machine shop

6 · copper segregation policy machine shop

7 · copper machinability chart

Check out our welded stainless steel box selection for the very best in unique or custom, handmade pieces from our boxes & bins shops.

Copper is a versatile and highly sought-after material in CNC machining due to its excellent electrical and thermal conductivity, corrosion .

Understanding Copper and Its Alloys for CNC Machining. Copper, admired for its excellent properties, is a metallic superstar in the world of CNC machining. Here’s what sets it . Copper CNC machining involves using computer-controlled tools and machines to fabricate copper materials into desired shapes. The CNC machining process controls complex devices such as mills, grinders, and . Copper, renowned for its electrical and thermal conductivity, plays a pivotal role in modern manufacturing and is a common material used in CNC machining. This guide delves deep into the world of copper machining, .Let’s look at all the essential details you need for your next CNC machining project, from the different alloys to critical considerations when machining this material. A copper part made with CNC machining.

You can efficiently machine copper alloys with various methods, including CNC copper milling. This automated process employs computerized controls to manage multi-point rotary cutting tools. As these tools rotate and traverse the . To overcome these issues, manufacturers rely on advanced CNC machining techniques and choose specific copper alloys designed to improve machinability. In this guide, we’ll explore the properties that affect copper’s .

Copper CNC machining refers to the process of using computer numerical control machine tools to process copper materials. The CNC machine automatically controls the movement of the tool according to pre-programmed .Another technique for machining copper is CNC turning, where the tool remains stationary, while the workpiece moves to produce the desired shape. CNC turning is an adaptable machining system used to make many electronic and .

Copper is a versatile and highly sought-after material in CNC machining due to its excellent electrical and thermal conductivity, corrosion resistance, and machinability. This guide explores the material properties of copper that make it ideal for various applications and shares effective techniques for machining copper using CNC technology.

Understanding Copper and Its Alloys for CNC Machining. Copper, admired for its excellent properties, is a metallic superstar in the world of CNC machining. Here’s what sets it apart: Impressive machinability; Ductility; Impact strength; Resistance to corrosion and wear Copper CNC machining involves using computer-controlled tools and machines to fabricate copper materials into desired shapes. The CNC machining process controls complex devices such as mills, grinders, and lathes to make precise and intricate features on copper parts. Generally, most CNC copper parts have good machinability, ductility, and impact strength. They also show a high thermal and electrical conductivity, corrosion, and wear resistance. Another benefit of CNC machining for copper parts encompasses good formability in both hot and cold processes.

Copper, renowned for its electrical and thermal conductivity, plays a pivotal role in modern manufacturing and is a common material used in CNC machining. This guide delves deep into the world of copper machining, unraveling its intricacies, techniques, and applications.Let’s look at all the essential details you need for your next CNC machining project, from the different alloys to critical considerations when machining this material. A copper part made with CNC machining.You can efficiently machine copper alloys with various methods, including CNC copper milling. This automated process employs computerized controls to manage multi-point rotary cutting tools. As these tools rotate and traverse the workpiece’s surface, they gradually shape it . To overcome these issues, manufacturers rely on advanced CNC machining techniques and choose specific copper alloys designed to improve machinability. In this guide, we’ll explore the properties that affect copper’s machinability, the best alloys to use, and effective CNC techniques to achieve optimal results.

Copper CNC machining refers to the process of using computer numerical control machine tools to process copper materials. The CNC machine automatically controls the movement of the tool according to pre-programmed instructions to accurately cut, engrave or shape the copper material.Another technique for machining copper is CNC turning, where the tool remains stationary, while the workpiece moves to produce the desired shape. CNC turning is an adaptable machining system used to make many electronic and mechanical components. Copper is a versatile and highly sought-after material in CNC machining due to its excellent electrical and thermal conductivity, corrosion resistance, and machinability. This guide explores the material properties of copper that make it ideal for various applications and shares effective techniques for machining copper using CNC technology. Understanding Copper and Its Alloys for CNC Machining. Copper, admired for its excellent properties, is a metallic superstar in the world of CNC machining. Here’s what sets it apart: Impressive machinability; Ductility; Impact strength; Resistance to corrosion and wear

Copper CNC machining involves using computer-controlled tools and machines to fabricate copper materials into desired shapes. The CNC machining process controls complex devices such as mills, grinders, and lathes to make precise and intricate features on copper parts. Generally, most CNC copper parts have good machinability, ductility, and impact strength. They also show a high thermal and electrical conductivity, corrosion, and wear resistance. Another benefit of CNC machining for copper parts encompasses good formability in both hot and cold processes.

Copper, renowned for its electrical and thermal conductivity, plays a pivotal role in modern manufacturing and is a common material used in CNC machining. This guide delves deep into the world of copper machining, unraveling its intricacies, techniques, and applications.Let’s look at all the essential details you need for your next CNC machining project, from the different alloys to critical considerations when machining this material. A copper part made with CNC machining.You can efficiently machine copper alloys with various methods, including CNC copper milling. This automated process employs computerized controls to manage multi-point rotary cutting tools. As these tools rotate and traverse the workpiece’s surface, they gradually shape it . To overcome these issues, manufacturers rely on advanced CNC machining techniques and choose specific copper alloys designed to improve machinability. In this guide, we’ll explore the properties that affect copper’s machinability, the best alloys to use, and effective CNC techniques to achieve optimal results.

Copper CNC machining refers to the process of using computer numerical control machine tools to process copper materials. The CNC machine automatically controls the movement of the tool according to pre-programmed instructions to accurately cut, engrave or shape the copper material.

turning copper speeds and feeds

pil metal box discogs

Auciello Iron Works, Inc. specializes in the fabrication of: • Custom Made Products in Steel, Stainless Steel, and Aluminum • Structural Steel and Architecturally Exposed Structural Steel (AESS) • Miscellaneous Metals

copper cnc machine|end mills for copper